содержание .. 1004 1005 1006 1007 ..

Nissan Murano Z51. Manual - part 1006

ENGINE MAINTENANCE

MA-19

< PERIODIC MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

M

B

MA

N

O

A

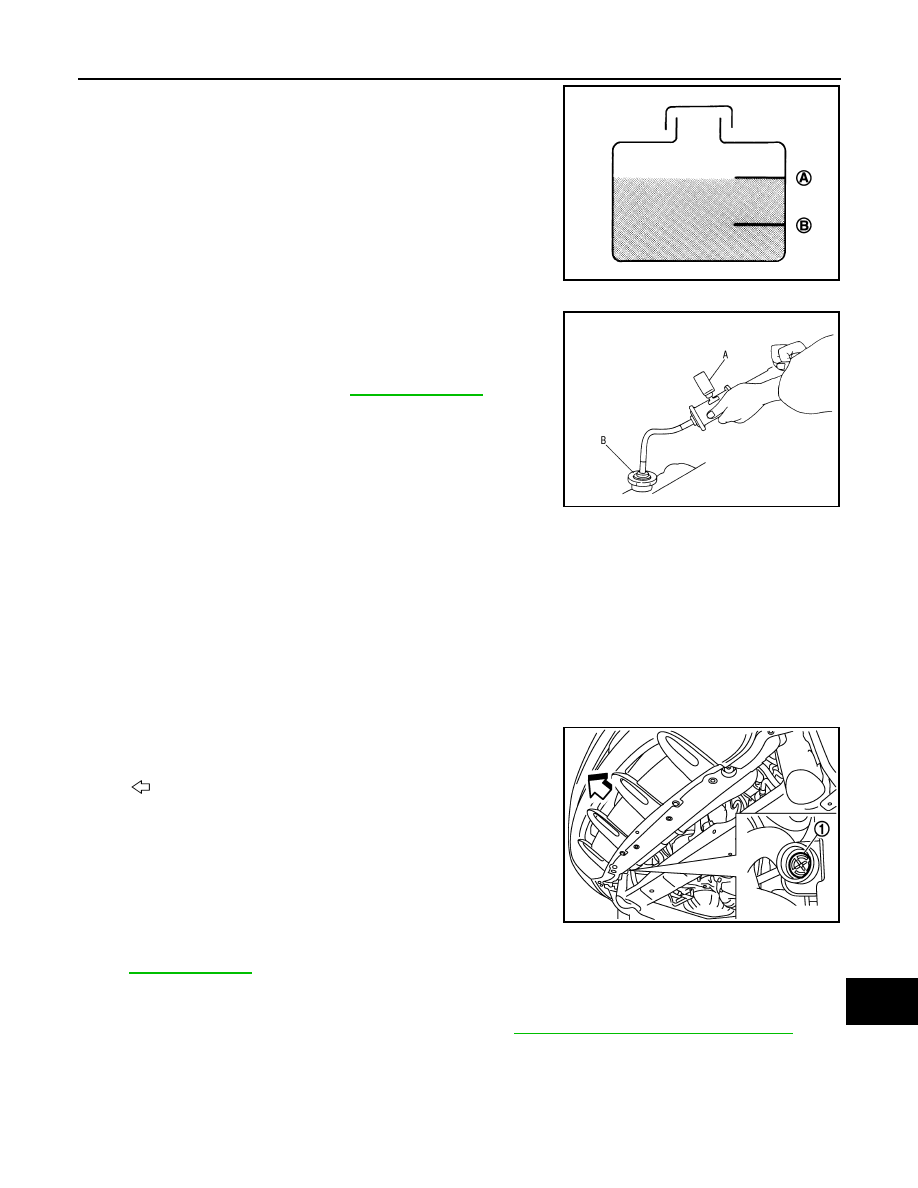

• Check if the reservoir tank engine coolant level is within the “MIN”

to “MAX” when the engine is cool.

• Adjust the engine coolant level if necessary.

LEAKAGE

• To check for leakage, apply pressure to the cooling system with the

radiator cap tester (commercial service tool) (A) and radiator cap

tester adapter (commercial service tool) (B).

WARNING:

Never remove radiator cap when engine is hot. Serious burns

could occur from high-pressure engine coolant escaping from

radiator.

CAUTION:

Higher test pressure than specified may cause radiator dam-

age.

NOTE:

In a case that engine coolant decreases, replenish radiator with engine coolant.

• If anything is found, repair or replace damaged parts.

ENGINE COOLANT : Draining

INFOID:0000000005516144

WARNING:

• To avoid being scalded, never change engine coolant when the engine is hot.

• Wrap a thick cloth around radiator cap and carefully remove radiator cap. First, turn radiator cap a

quarter of a turn to release built-up pressure. Then turn radiator cap all the way.

1.

Remove engine under cover.

2.

Open radiator drain plug (1) at the bottom of radiator, and then

remove radiator cap.

When draining all of engine coolant in the system, open water drain plugs on cylinder block. Refer

to

.

3.

Remove reservoir tank if necessary, and drain engine coolant and clean reservoir tank before installing.

4.

Check drained engine coolant for contaminants such as rust, corrosion or discoloration.

If contaminated, flush the engine cooling system. Refer to

MA-21, "ENGINE COOLANT : Flushing"

ENGINE COOLANT : Refilling

INFOID:0000000005516145

1.

Install reservoir tank if removed and radiator drain plug.

CAUTION:

Be sure to clean drain plug and install with new O-ring.

A

: MAX

B

: MIN

JPBIA0102ZZ

Testing pressure

: Refer to

.

PBIC5121J

: Vehicle front

JPBIA1684ZZ