Nissan Murano Z51 (2013 year). Manual - part 88

ENGINE SPEED SIGNAL CIRCUIT

STC-9

< DTC/CIRCUIT DIAGNOSIS >

C

D

E

F

H

I

J

K

L

M

A

B

STC

N

O

P

ENGINE SPEED SIGNAL CIRCUIT

Description

INFOID:0000000008455035

ECM sends engine speed signal to power steering control unit.

Diagnosis Procedure

INFOID:0000000008455036

1.

PERFORM ECM SELF-DIAGNOSIS

With CONSULT

1.

Turn the ignition switch ON.

CAUTION:

Never start the engine

2.

Perform “ENGINE” self-diagnosis. Refer to

Is any DTC detected?

YES

>> Check the DTC.

NO

>> GO TO 2.

2.

CHECK HARNESS BETWEEN ECM AND POWER STEERING CONTROL UNIT

1.

Turn the ignition switch OFF.

2.

Disconnect ECM harness connectors.

3.

Disconnect power steering control unit harness connector.

4.

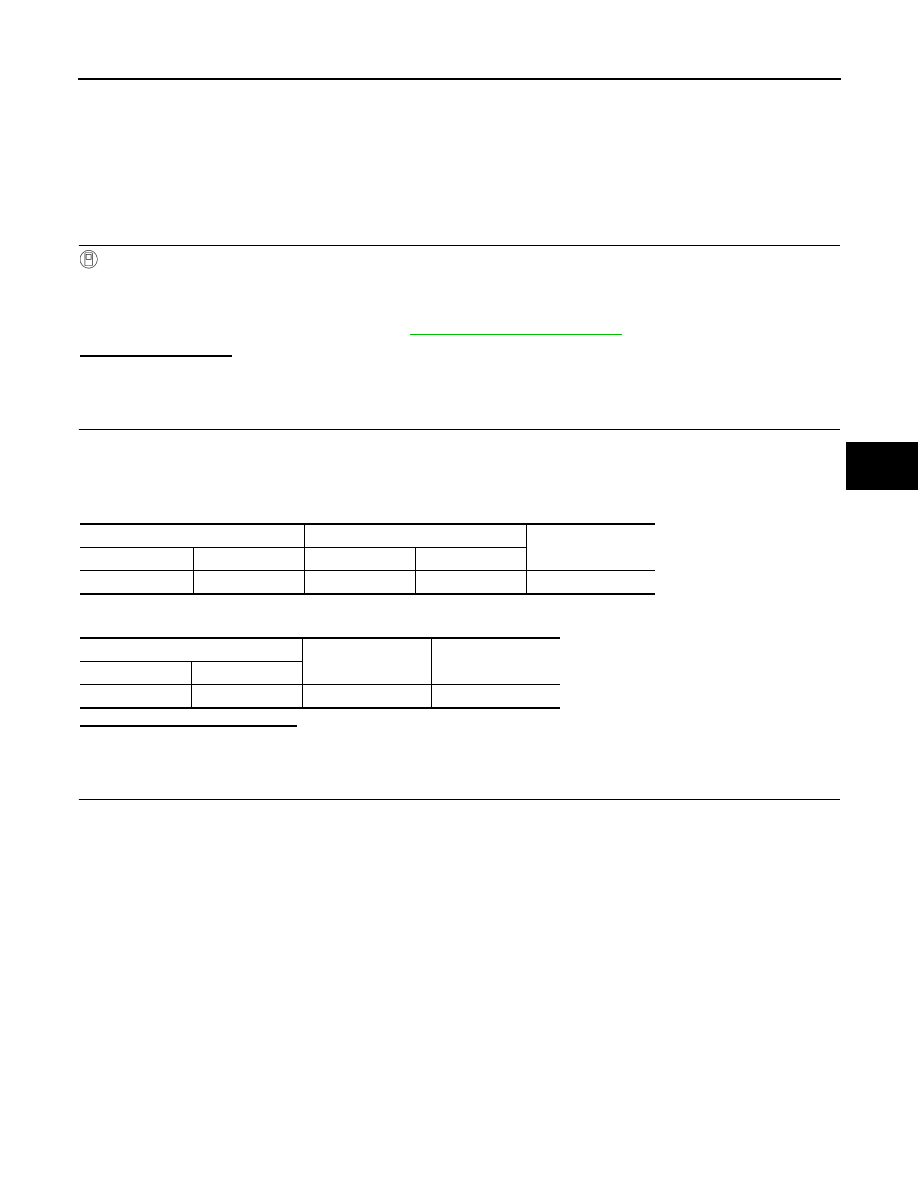

Check continuity between ECM harness connector and power steering control unit harness connector.

5.

Check continuity between power steering control unit harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair or replace damaged parts.

3.

CHECK ENGINE SPEED SIGNAL (1)

1.

Connect ECM harness connectors.

2.

Check signal between ECM harness connector and ground with oscilloscope.

ECM

Power steering control unit

Continuity

Connector

Terminal

Connector

Terminal

E16

94

M61

10

Existed

Power steering control unit

—

Continuity

Connector

Terminal

M61

10

Ground

Not existed

Revision: 2012 September

2013 MURANO