Nissan Murano Z51 (2013 year). Manual - part 87

ST-100

< REMOVAL AND INSTALLATION >

[WITHOUT HEATED STEERING WHEEL]

POWER STEERING OIL PUMP

2.

Remove rear cover mounting bolts, and then remove rear cover from body assembly.

CAUTION:

• Fix oil pump with a vise if necessary.

• Use copper plates when fixing with a vise.

3.

Remove O-ring from body assembly.

4.

Remove rear side plate from cartridge, and then remove Teflon ring and O-ring from rear side plate.

5.

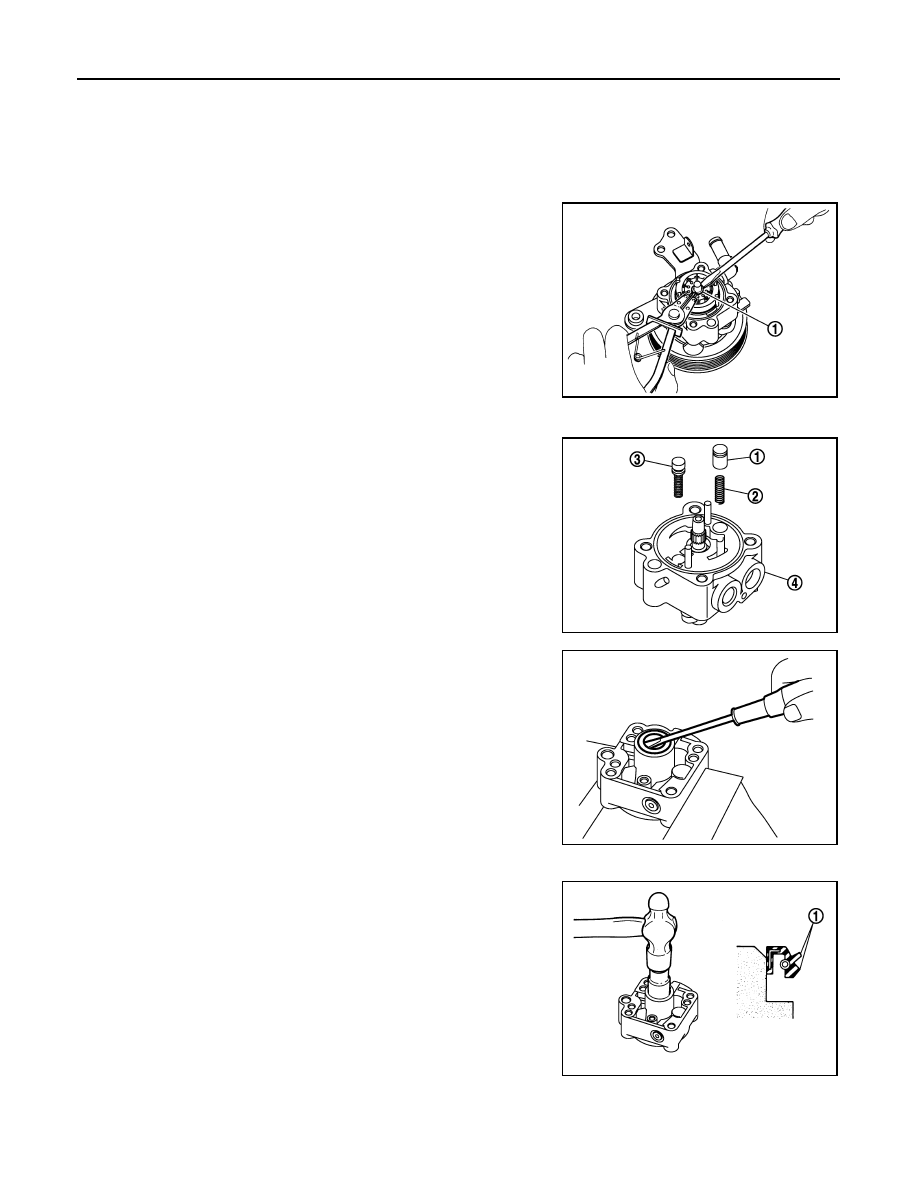

Remove rotor snap ring (1) using a snap ring pliers, and remove

cam ring, rotor and vane from body assembly.

CAUTION:

When removing the snap ring, never damage the pulley

shaft.

6.

Remove front side plate.

7.

Remove cartridge, flow control valve (1), flow control valve

spring (2) and flow control valve sub assembly (3) from body

assembly (4).

CAUTION:

Never drop and damage flow control valve and flow control

valve sub assembly when removing.

8.

Remove oil seal from body assembly.

9.

Remove mounting bolt of suction pipe, and then remove suction

pipe from body assembly.

10. Remove pulley from body assembly.

11. Remove front bracket from body assembly.

12. Remove oil seal from body assembly using a flat-bladed screw-

driver.

CAUTION:

Never damage the body assembly.

ASSEMBLY

1.

Apply recommended grease to oil seal lips (1). Apply recom-

mended fluid to around oil seal. Install oil seal to body assembly

using a drift (commercial service tool).

CAUTION:

• Never reuse the oil seal.

• Fix oil pump with a vise if necessary.

• Use copper plates when fixing with a vise.

2.

Install front bracket to body assembly.

3.

Install pulley to body assembly.

4.

If dowel pin has been removed, insert it into body assembly by

hand. If it cannot be inserted by hand, lightly tap with a hammer.

JSGIA0328ZZ

JSGIA0329ZZ

JSGIA0331ZZ

JSGIA0330ZZ

Revision: 2012 September

2013 MURANO