Nissan Murano Z51 (2012 year). Manual - part 29

FRONT DRIVE SHAFT

FAX-43

< REMOVAL AND INSTALLATION >

[AWD]

C

E

F

G

H

I

J

K

L

M

A

B

FAX

N

O

P

FRONT DRIVE SHAFT

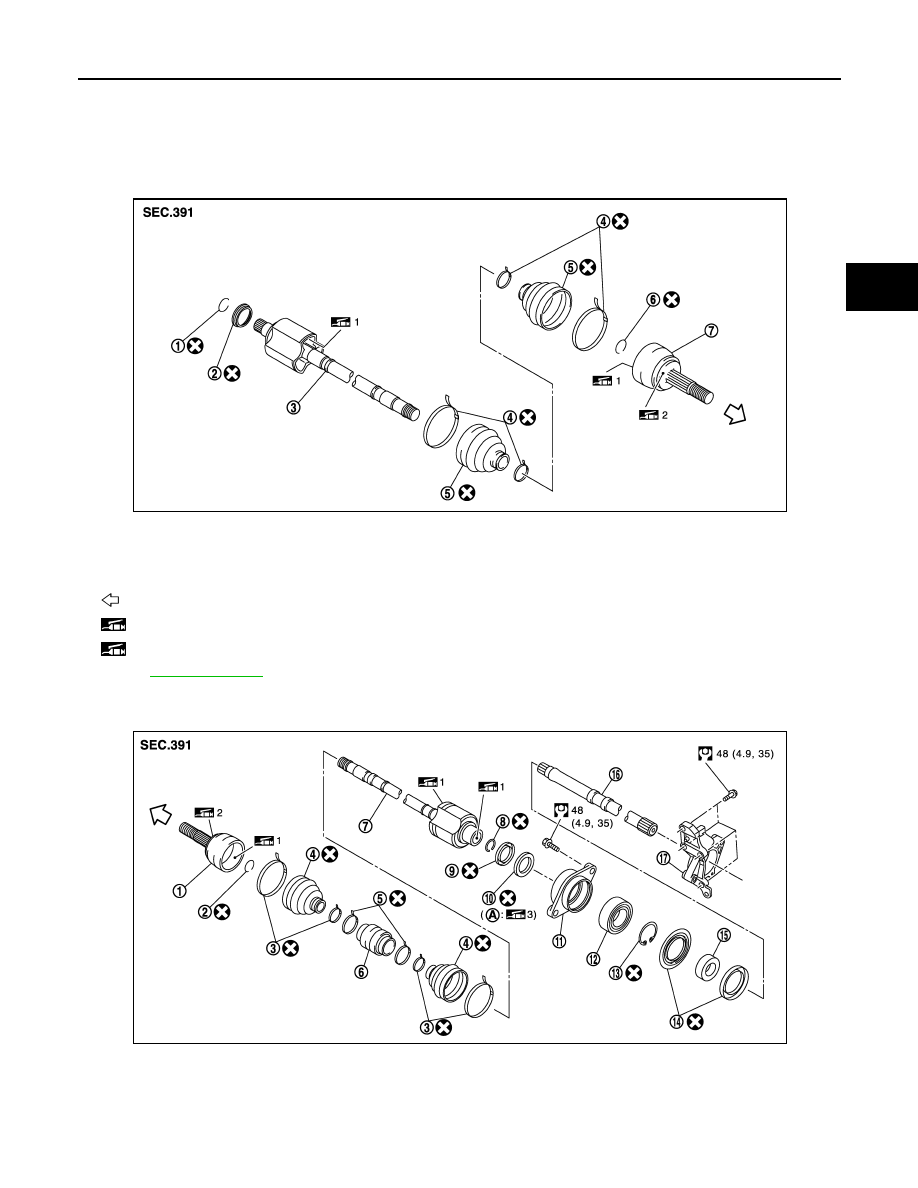

Exploded View

INFOID:0000000007541227

LEFT SIDE

RIGHT SIDE

1.

Circular clip

2.

Dust shield

3.

Housing assembly

4.

Boot band

5.

Boot

6.

Circular clip

7.

Joint sub-assembly

: Wheel side

1: Fill NISSAN Genuine grease or equivalent.

2: Apply paste [service parts (440037S000)].

Refer to

for symbols not described on the above.

JPDIF0243ZZ

1.

Joint sub-assembly

2.

Circular clip

3.

Boot band

4.

Boot

5.

Damper band

6.

Dynamic damper

7.

Housing assembly

8.

Circular clip

9.

Dust shield

10. Oil seal

11.

Bearing housing

12. Bearing bracket

JPDIF0241GB

Revision: 2013 February

2012 MURANO