Nissan Murano Z50 (2005 year). Manual - part 215

AUTOMATIC DRIVE POSITIONER

SE-81

C

D

E

F

G

H

J

K

L

M

A

B

SE

Revision: 2005 August

2005 Murano

2.

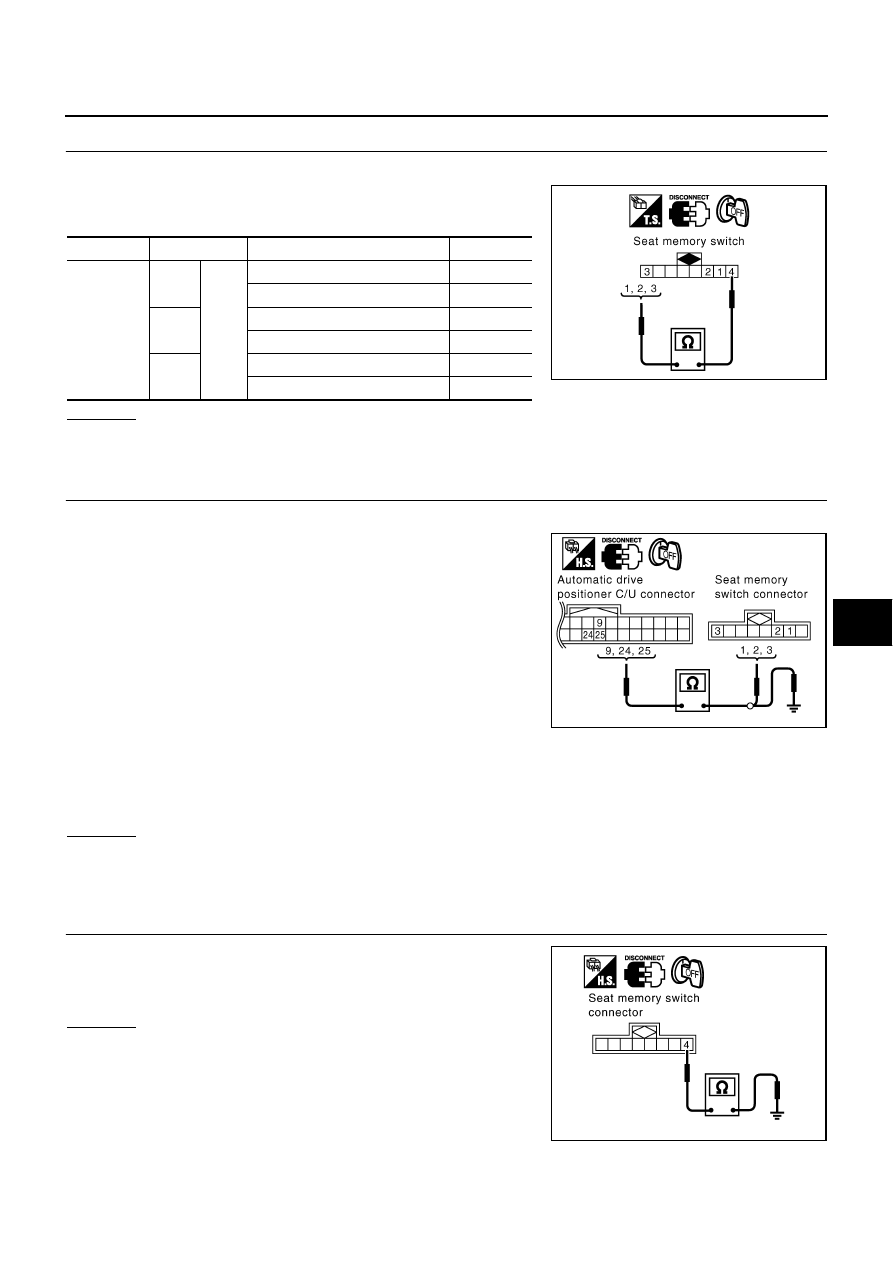

CHECK SEAT MEMORY SWITCH

1.

Turn ignition switch OFF.

2.

Disconnect seat memory switch connector.

3.

Check continuity between seat memory switch as follows.

OK or NG

OK

>> GO TO 3.

NG

>> Replace seat memory switch.

3.

CHECK HARNESS CONTINUITY

1.

Disconnect automatic drive positioner control unit connector.

2.

Check continuity between automatic drive positioner control unit

connector M19 terminals 9 (LG/B), 24 (R/Y), 25 (P/L) and seat

memory switch connector D3 terminals 1 (LG/B), 2 (P/L), 3 (R/

Y).

3.

Check continuity between automatic drive positioner control unit

connector M19 terminals 9 (LG/B), 24 (R/Y), 25 (P/L) and

ground.

OK or NG

OK

>> GO TO 4.

NG

>> Repair or replace harness between automatic drive positioner control unit and seat memory

switch.

4.

CHECK SEAT MEMORY SWITCH GROUND CIRCUIT

Check continuity between seat memory switch D3 terminal 4 (B) and

ground.

OK or NG

OK

>> Replace automatic drive positioner control unit.

NG

>> Repair or replace harness between seat memory switch

and ground.

Connector

Terminal

Condition

Continuity

D3

1

4

Memory switch 1 ON

Yes.

Memory switch 1: OFF

No.

2

Memory switch 2: ON

Yes.

Memory switch 2: OFF

No.

3

Set switch: ON

Yes.

Set switch: OFF

No.

PIIA4575E

9 (LG/B) – 1 (LG/B)

: Continuity should exist.

24 (R/Y) – 3 (R/Y)

: Continuity should exist.

25 (P/L) – 2 (P/L)

: Continuity should exist.

9 (LG/B) – Ground

: Continuity should not exist.

24 (R/Y) – Ground

: Continuity should not exist.

25 (P/L) – Ground

: Continuity should not exist.

PIIA4576E

4 (B) – Ground

: Continuity should exist.

PIIA4821E