Nissan Murano Z50 (2003 year). Manual - part 129

CAMSHAFT

EM-73

C

D

E

F

G

H

I

J

K

L

M

A

EM

Revision; 2004 April

2003 Murano

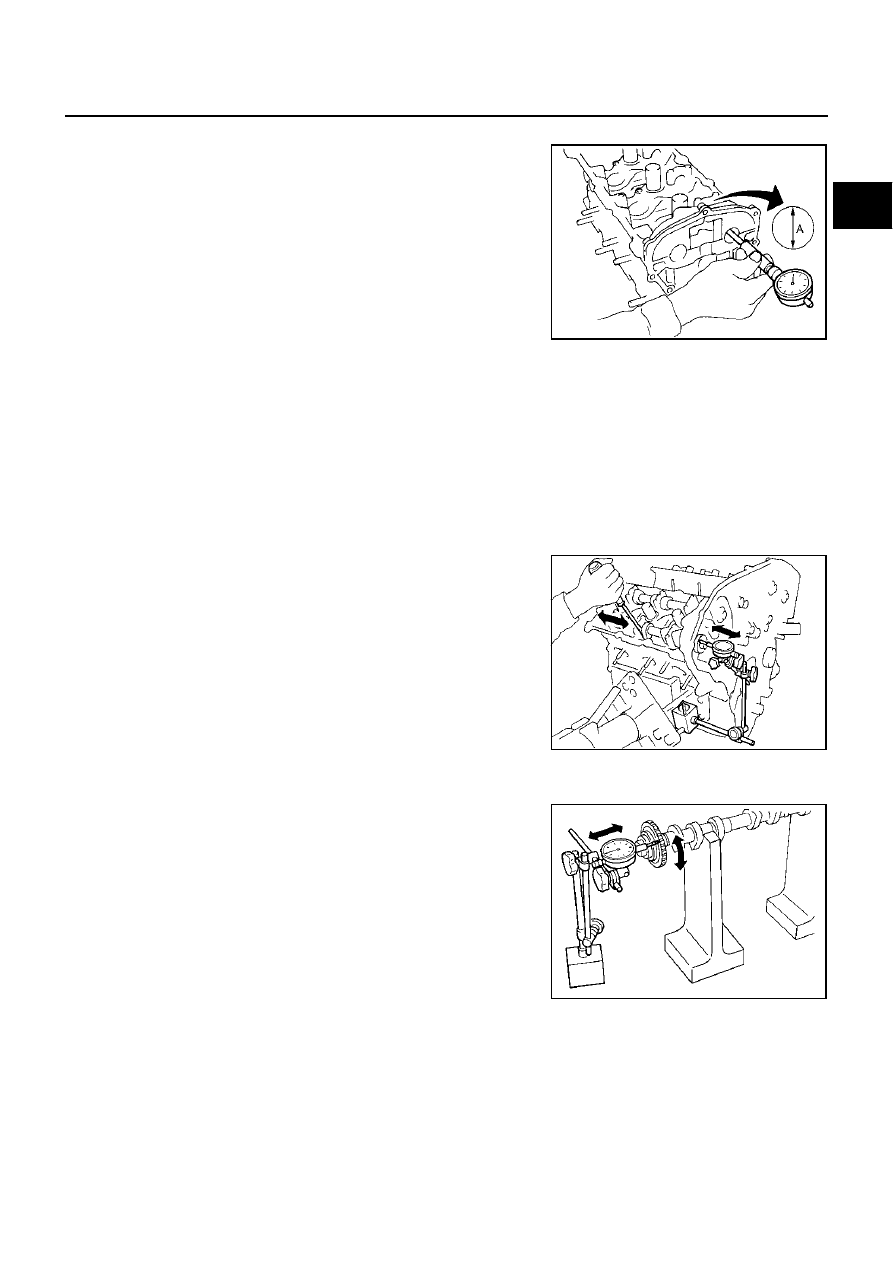

Inner Diameter of Camshaft Bracket

●

Tighten camshaft bracket bolt with specified torque.

●

Using inside micrometer, measure inner diameter “A” of cam-

shaft bracket.

Calculation of Camshaft Journal Clearance

●

(Journal clearance) = (inner diameter of camshaft bracket) –

(outer diameter of camshaft journal).

●

When out of the limit, replace either or both camshaft and cylinder head.

NOTICE:

Inner diameter of camshaft bracket is manufactured together with cylinder head. Replace the whole cylin-

der head assembly.

Camshaft End Play

●

Install dial gauge in thrust direction on front end of camshaft.

Measure end play of dial gauge when camshaft is moved for-

ward/backward (in direction to axis).

●

When out of the limit, replace with new camshaft and measure

again.

●

When out of the limit again, replace with new cylinder head.

Camshaft Sprocket Runout

1.

Put V block on precise flat bed, and support No. 2 and No. 4 journal of camshaft.

2.

Using dial gauge and measure camshaft sprocket runout. (Total

indicator reading)

●

If it exceeds the limit, replace camshaft sprocket.

Standard inner diameter:

No. 1

: 26.000 - 26.021 mm (1.0236 - 1.0244 in)

No. 2, 3, 4

: 23.500 - 23.521 mm (0.9252 - 0.9260 in)

Standard:

No. 1

: 0.045 - 0.086 mm (0.0018 - 0.0034 in)

No. 2, 3, 4

: 0.035 - 0.076 mm (0.0014 - 0.0030 in)

Limit

: 0.15 mm (0.0059 in)

PBIC1645E

Standard

: 0.115 - 0.188 mm (0.0045 - 0.0074 in)

Limit

: 0.24 mm (0.0094 in)

SEM864E

Limit

: 0.15 mm (0.0059 in)

PBIC0930E