Nissan Murano Z50 (2003 year). Manual - part 127

FUEL INJECTOR AND FUEL TUBE

EM-41

C

D

E

F

G

H

I

J

K

L

M

A

EM

Revision; 2004 April

2003 Murano

●

When installing O-ring, be careful not to scratch it with tool or fingernails. Also be careful not

to twist or stretch O-ring. If O-ring was stretched while it was being attached, do not insert it

quickly into fuel tube.

●

Insert fuel damper straight into fuel tube.

●

Tighten mounting bolts evenly in turn.

●

After tightening mounting bolts, make sure that there is no gap between flange and fuel tube.

2.

Install O-rings to fuel injector paying attention to the items below.

CAUTION:

●

Upper and lower O-ring are different. Be careful not to confuse them.

●

Handle O-ring with bare hands. Never wear gloves.

●

Lubricate O-ring with new engine oil.

●

Do not clean O-ring with solvent.

●

Make sure that O-ring and its mating part are free of foreign material.

●

When installing O-ring, be careful not to scratch it with tool or fingernails. Also be careful not to

twist or stretch O-ring. If O-ring was stretched while it was being attached, do not insert it

quickly into fuel tube.

●

Insert O-ring straight into fuel tube. Do not decenter or twist it.

3.

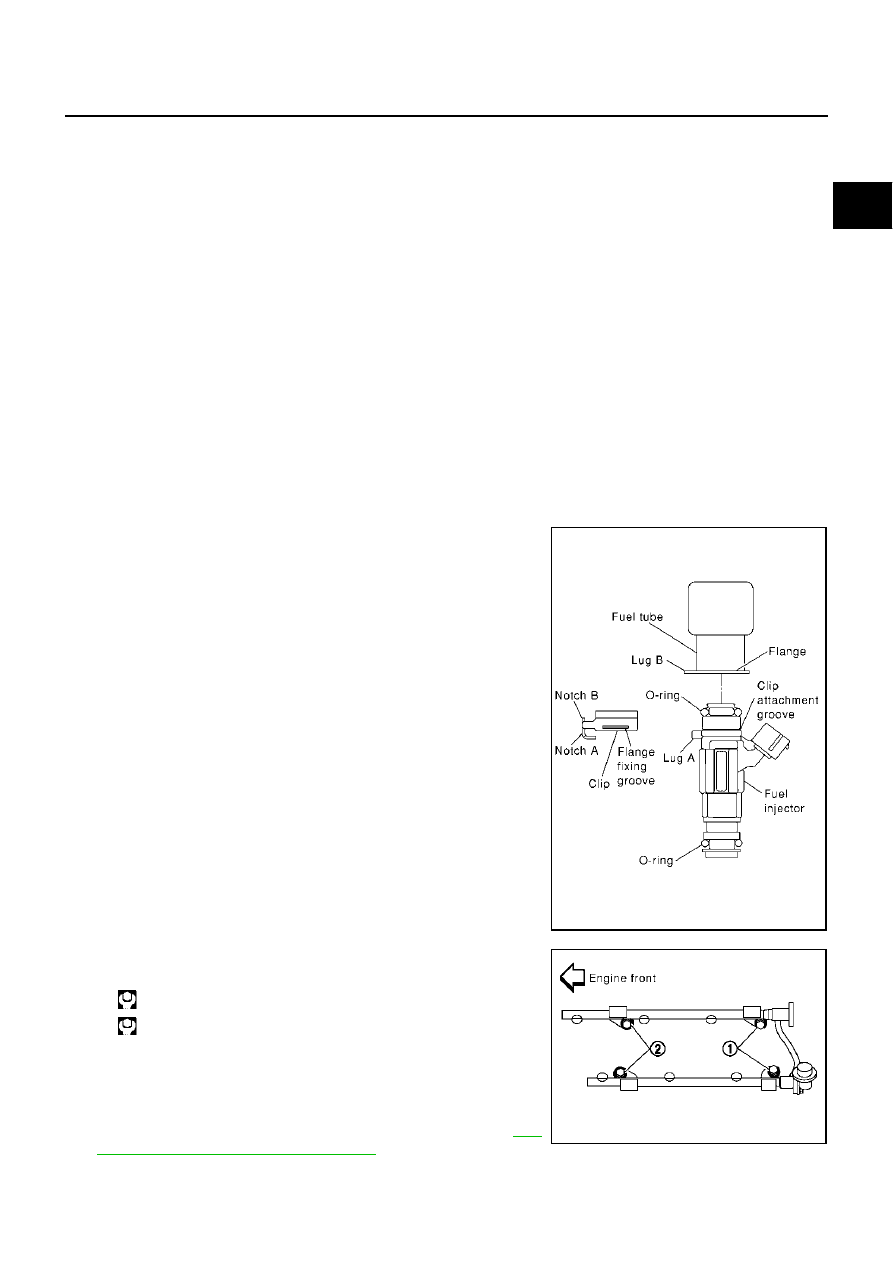

Install fuel injector to fuel tube with the following procedure.

a.

Insert clip into clip mounting groove on fuel injector.

●

Insert clip so that lug “A” of fuel injector matches notch “A” of

the clip.

CAUTION:

●

Do not reuse clip. Replace it with a new one.

●

Be careful to keep clip from interfering with O-ring. If

interference occurs, replace O-ring.

b.

Insert fuel injector into fuel tube with clip attached.

●

Insert it while matching it to the axial center.

●

Insert fuel injector so that lug “B” of fuel tube matches notch

“B” of the clip.

●

Make sure that fuel tube flange is securely fixed in flange fix-

ing groove on clip.

c.

Make sure that installation is complete by checking that fuel

injector does not rotate or come off.

4.

Tighten mounting bolts in two steps in numerical order shown in

figure.

CAUTION:

Be careful not to let tip of injector nozzle come in contact

with other parts.

5.

Connect fuel injector harness.

6.

Install intake manifold collector (upper and lower). Refer to

16, "INTAKE MANIFOLD COLLECTOR"

.

Fuel tube side

: Black

Nozzle side

: Green

PBIC1021E

1st step : 9.3 - 10.8 N·m (0.95 - 1.1 kg-m, 6.9 - 7.9 ft-lb)

2nd step : 20.6 - 26.5 N·m (2.1 - 2.7 kg-m, 16 - 19 ft-lb)

SEC999C