Nissan Murano Z50 (2003 year). Manual - part 128

TIMING CHAIN

EM-57

C

D

E

F

G

H

I

J

K

L

M

A

EM

Revision; 2004 April

2003 Murano

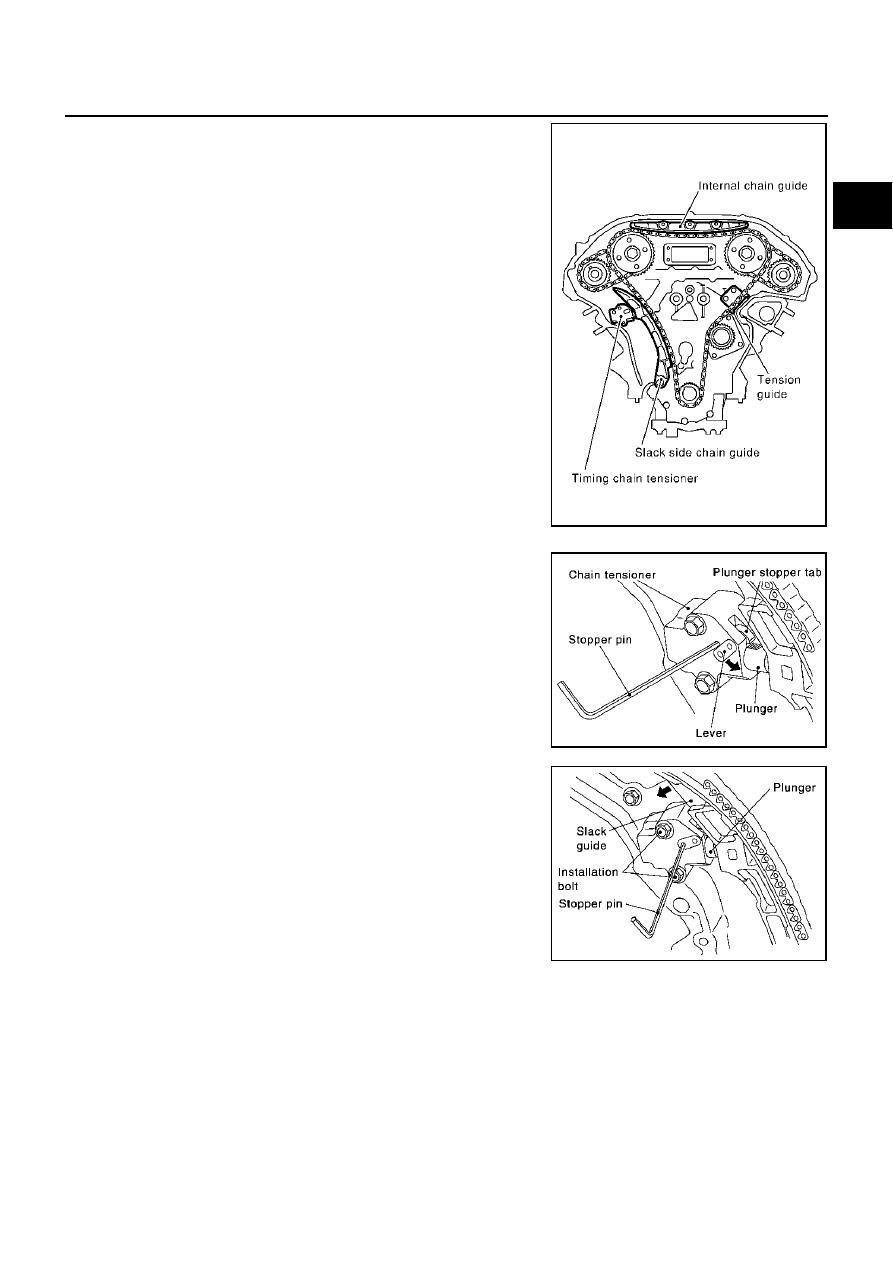

21. Remove internal chain guide, timing chain tensioner, tension

guide and slack guide.

●

Remove timing chain tensioner as follows:

a.

Pull lever down and release plunger stopper tab.

●

Plunger stopper tab can be pushed up to release (coaxial

structure with lever).

b.

Insert stopper pin into tensioner body hole to hold lever, and

keep the tab released.

NOTE:

An Allen wrench [2.5 mm (0.098 in)] is used for a stopper pin as

an example.

c.

Insert plunger into tensioner body by pressing the slack guide.

d.

Keep the slack guide pressed and hold it by pushing the stopper

pin through the lever hole and body hole.

e.

Remove the mounting bolts and remove the timing chain ten-

sioner.

22. Remove timing chain (primary) and crankshaft sprocket.

CAUTION:

●

After removing timing chain, do not turn the crankshaft and camshaft separately, or the valves

will strike the piston heads.

SEM731G

SEM732G

SEM733G