Nissan Murano Z50 (2003 year). Manual - part 125

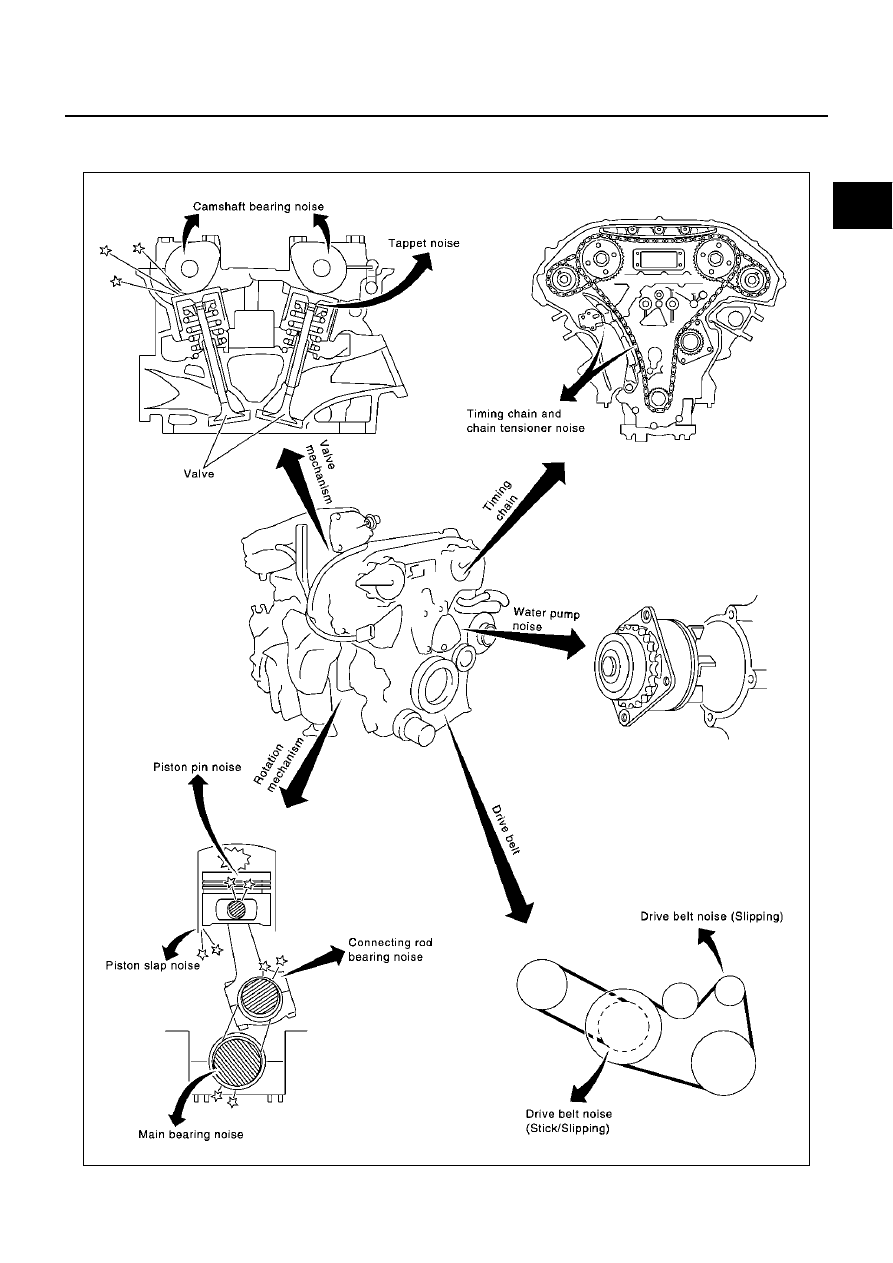

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

EM-9

C

D

E

F

G

H

I

J

K

L

M

A

EM

Revision; 2004 April

2003 Murano

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

PFP:00003

NVH Troubleshooting —Engine Noise

ABS00327

SEM706G