Nissan Murano Z51 (2008 year). Manual - part 247

IP-16

< ON-VEHICLE REPAIR >

INSTRUMENT PANEL ASSEMBLY

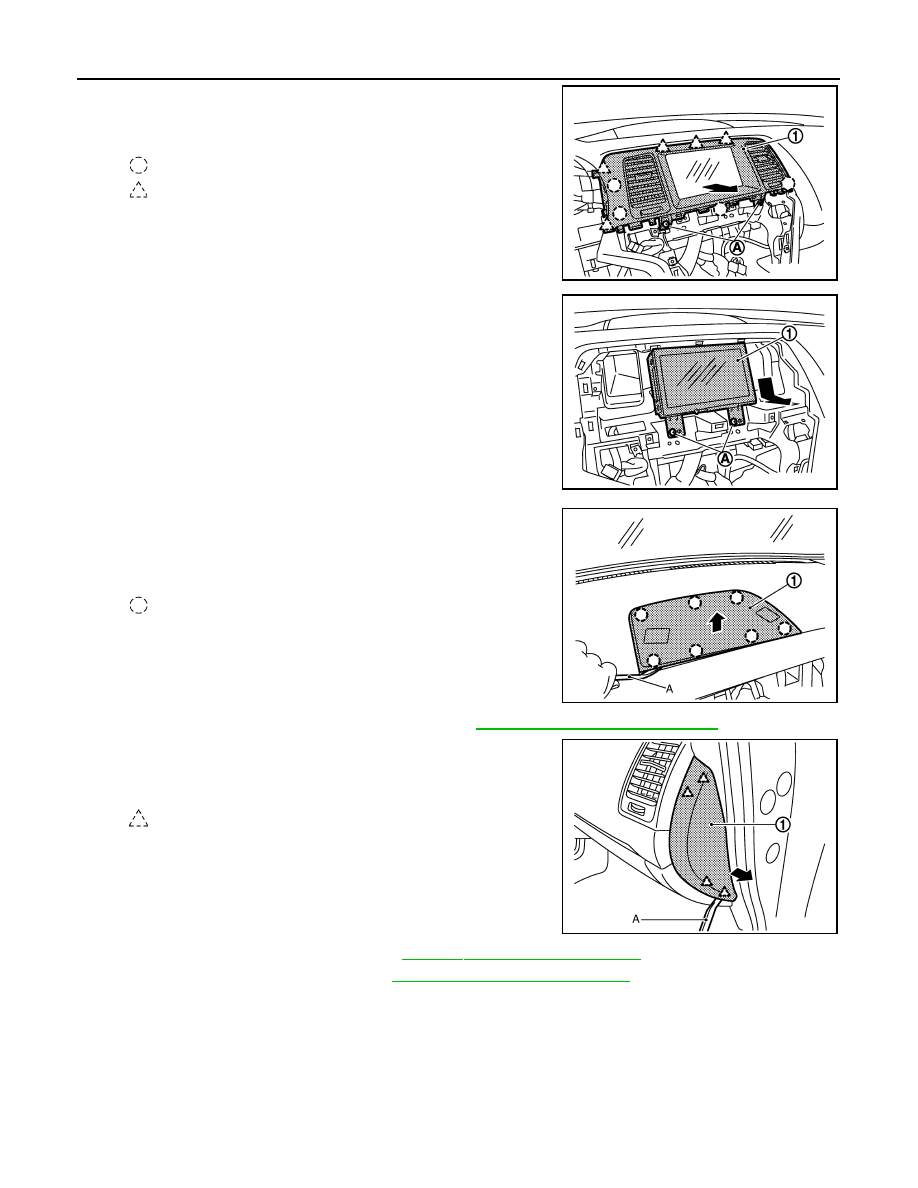

21. Remove center ventilator assembly.

• Remove center ventilator assembly (1) fixing screws (A).

• Pull back center ventilator assembly.

22. Remove display unit.

• Remove display unit (1) fixing screws (A).

• Pull toward the arrow direction.

• Disconnect harness connector.

23. Remove center speaker grille.

• Disengage center speaker grille (1) fixing clips with remover

tool (A).

• Pull up center speaker grille.

24. Remove center speaker. (with BOSE audio) Refer to

AV-531, "Removal and Installation"

.

25. Remove instrument side finisher RH.

• Insert a remover tool (A) into lower space.

• Pull the instrument side finisher RH (1) crosswise.

26. Remove front body side welt RH. Refer to

INT-19, "Removal and Installation"

27. Remove front pillar garnish RH. Refer to

INT-19, "Removal and Installation"

.

: Clip

: Pawl

JMJIA1325ZZ

JMJIA1326ZZ

: Clip

JMJIA1327ZZ

: Pawl

JMJIA1328ZZ

Revision: 2008 October

2009 Murano