Nissan Murano Z51 (2008 year). Manual - part 246

INT-40

< ON-VEHICLE REPAIR >

BACK DOOR TRIM

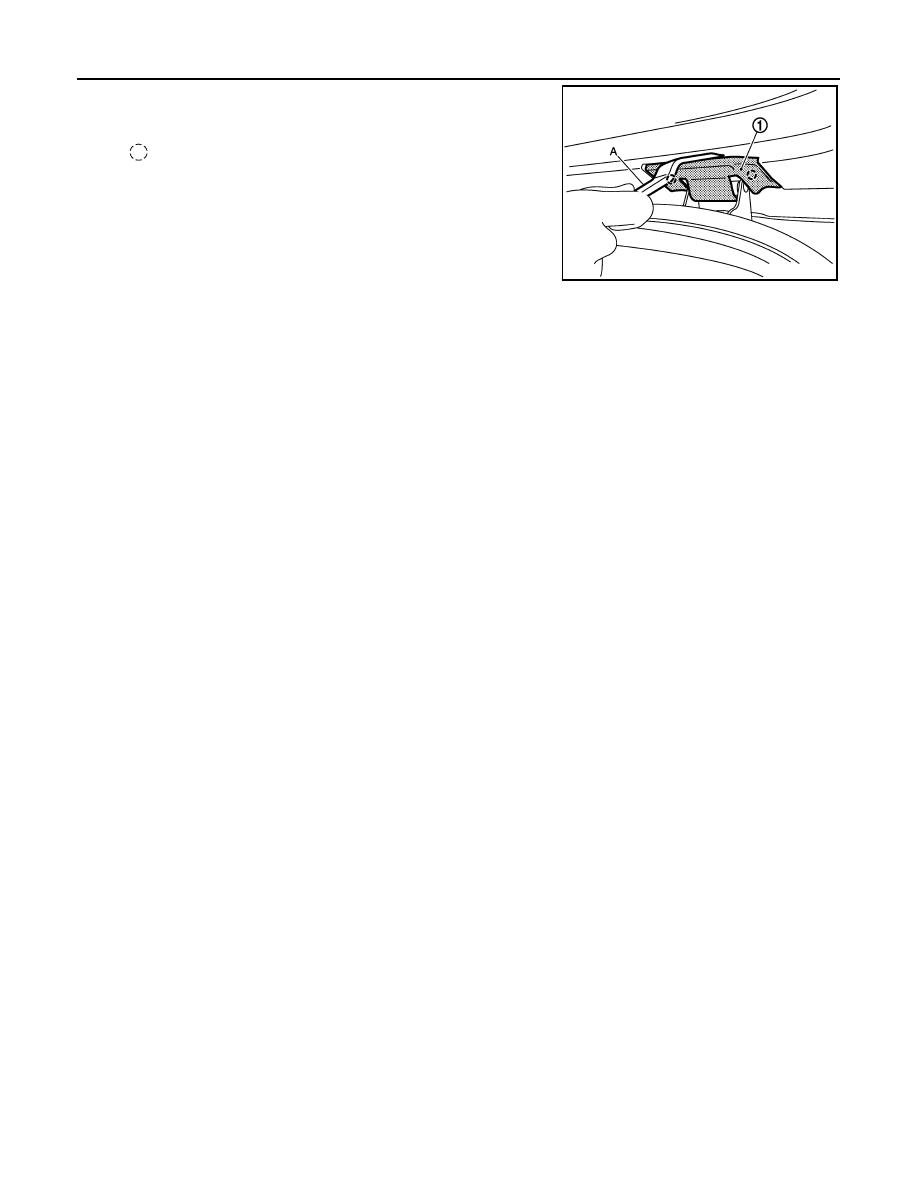

10. Disengage back door hinge cover (1) fixing clips with remover

tool (A) and then remove back door hinge cover(LH/RH).

INSTALLATION

Install in the reverse order of removal.

CAUTION:

When installing back door trim, check that clips are securely fitted in panel holes on body, and then

press them in.

: Clip

JMJIA1692ZZ

Revision: 2008 October

2009 Murano