Nissan Murano Z51 (2008 year). Manual - part 220

HA-56

< ON-VEHICLE REPAIR >

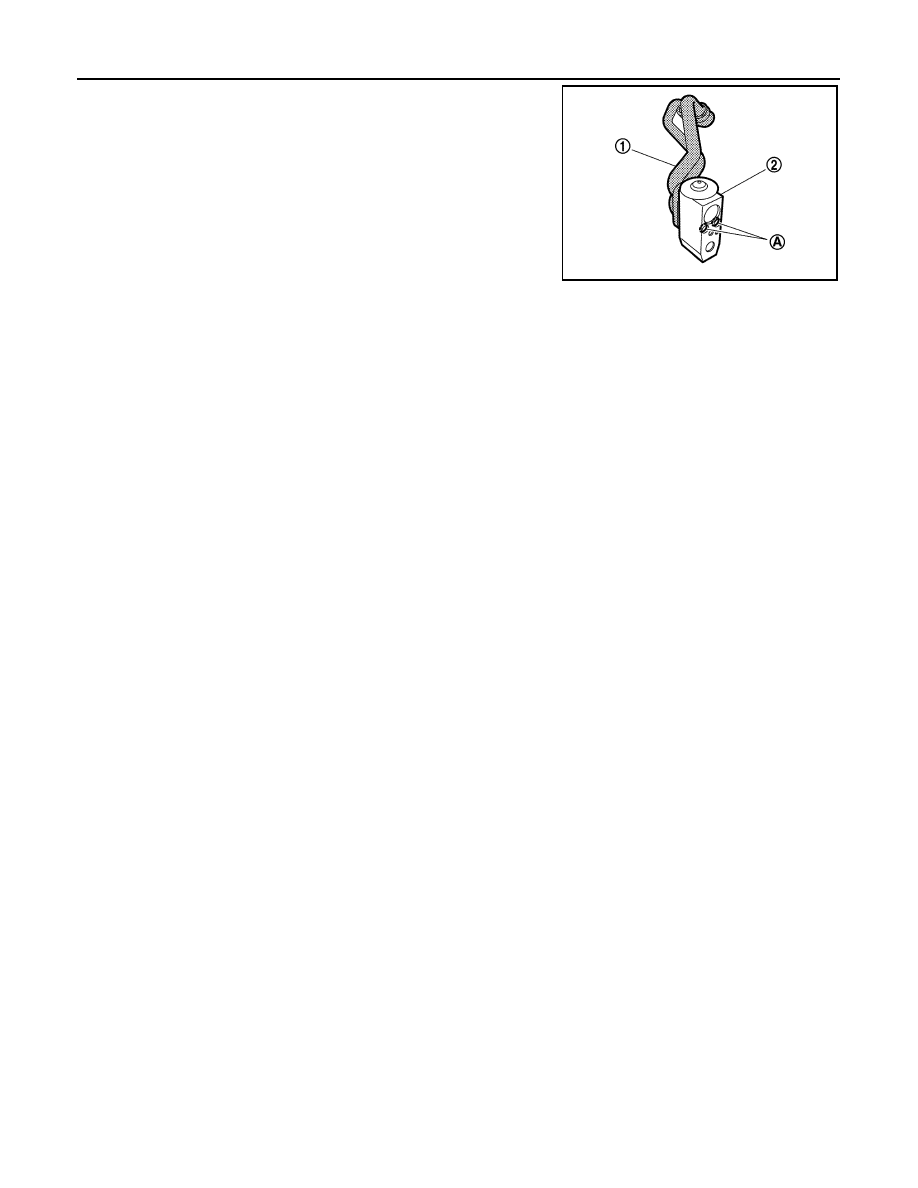

EVAPORATOR PIPE ASSEMBLY

10. Remove the mounting bolts (A), and then remove the evaporator

pipe (2) from the evaporator assembly (1).

CAUTION:

Cap or wrap the joint of the A/C piping and expansion valve

with suitable material such as vinyl tape to avoid the entry

of air.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

• Replace O-rings with new ones. Then apply compressor oil to them when installing.

• Check for leakages when recharging refrigerant.

JPIIA0547ZZ

Revision: 2008 October

2009 Murano