Nissan Murano Z51 (2008 year). Manual - part 209

FL-8

< ON-VEHICLE REPAIR >

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

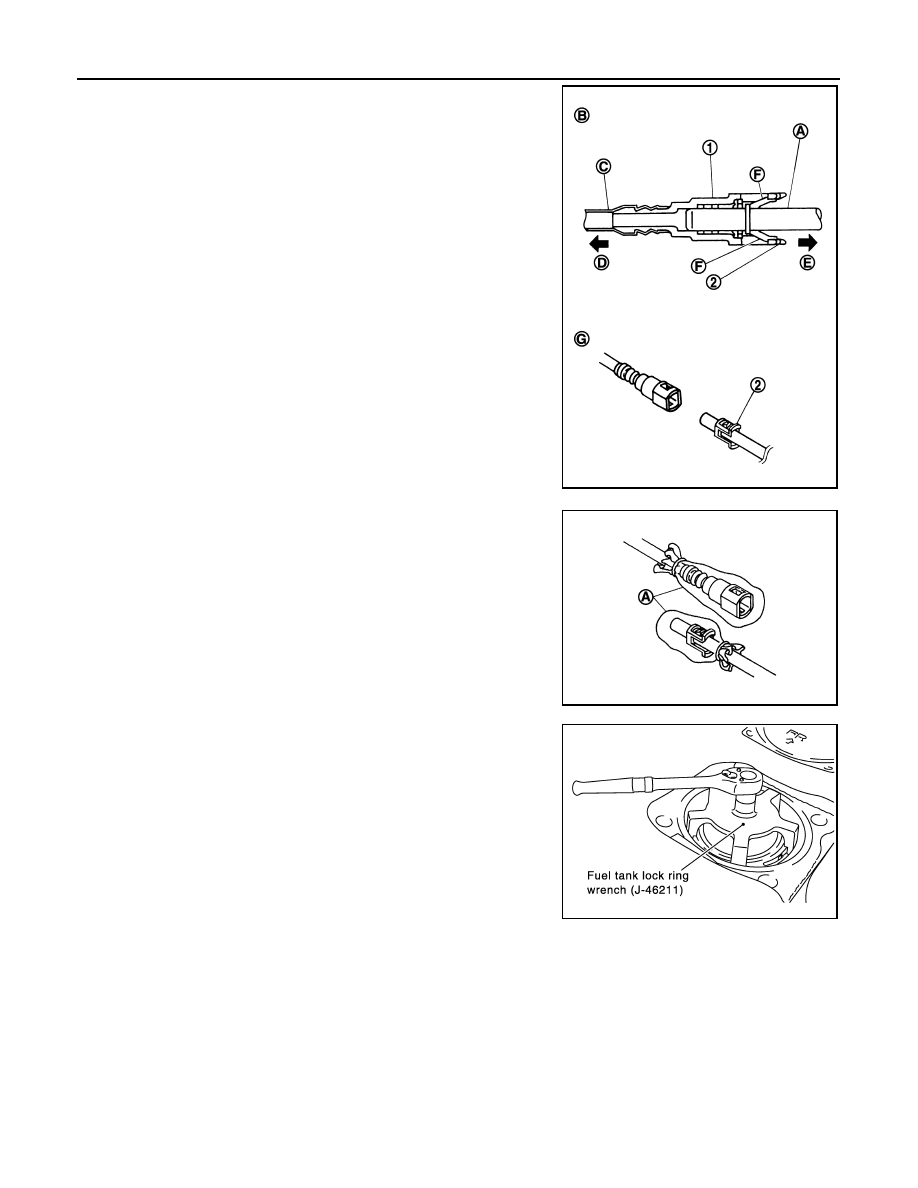

• Quick connector (1) can be disconnected when the tabs

(F) are completely depressed. Never twist it more than

necessary.

• Never use any tools to disconnected quick connector.

• Keep resin tube (C) away from heat. Be especially careful

when welding near the resin tube.

• Prevent acid liquid such as battery electrolyte, etc. from

getting on resin tube.

• Never bend or twist resin tube during installation and dis-

connection.

• Never remove the remaining retainer (2) on hard tube (or

the equivalent) (A) except when resin tube or retainer is

replaced.

• When resin tube or hard tube (or the equivalent) is

replaced, also replace retainer with new one.

• To keep the connecting portion clean and to avoid dam-

age and foreign materials, cover them completely with

plastic bags (A) or something similar.

8.

Remove retainer for main fuel level sensor unit, fuel filter and

fuel pump assembly and sub fuel level sensor unit with fuel tank

lock ring wrench (SST) by turning counterclockwise.

9.

Remove main fuel level sensor unit, fuel filter and fuel pump assembly, and sub fuel level sensor unit.

B

: Connection (cross-section)

D

: To under floor fuel line

E

: To fuel tank

G

: Disconnection

Retainer color: Green

JPBIA0130ZZ

JPBIA0135ZZ

SBIA0411E

Revision: 2008 October

2009 Murano