содержание .. 804 805 806 807 ..

Nissan Murano. Manual - part 806

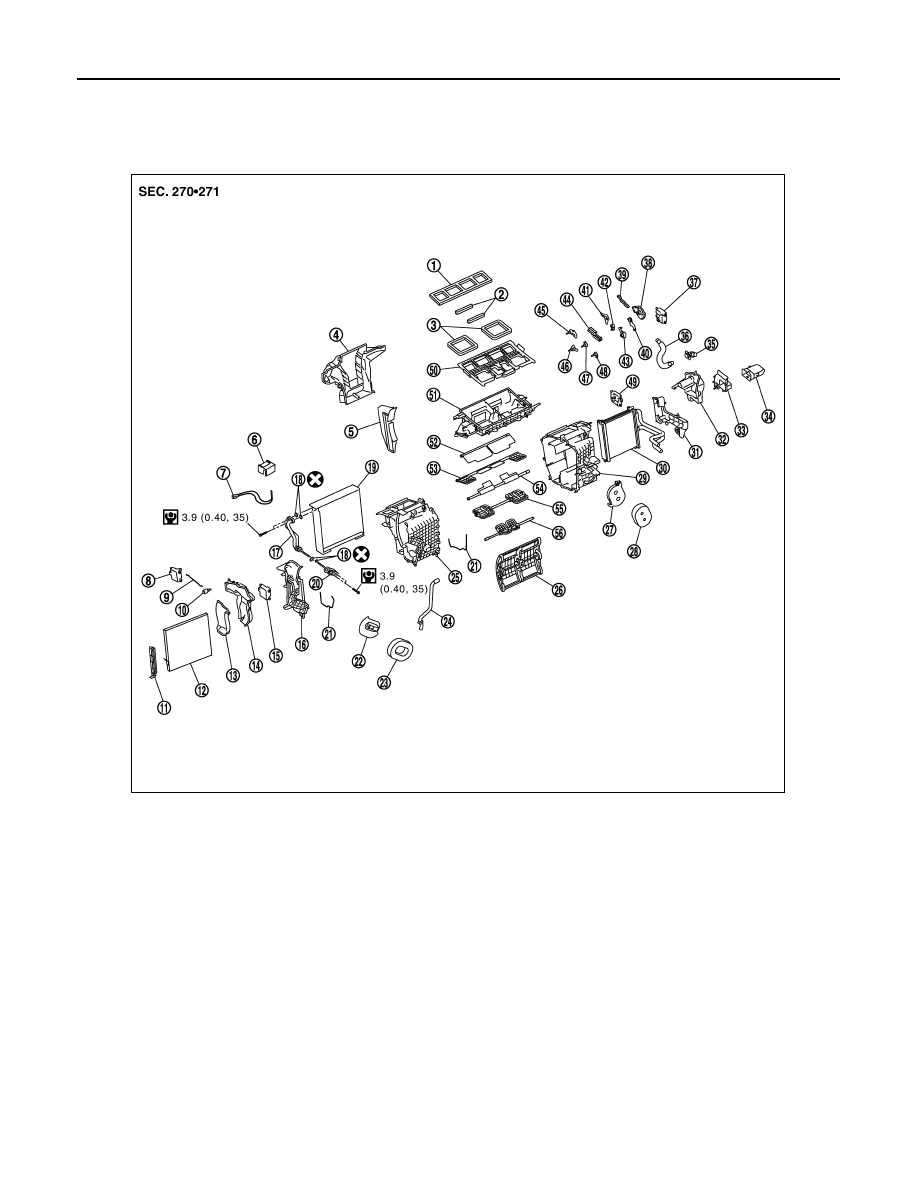

HA-60

< REMOVAL AND INSTALLATION >

EXPANSION VALVE

EXPANSION VALVE

Exploded View

INFOID:0000000009718662

1.

Ventilator seal

2.

Upper ventilator seal

3.

Defroster seal

4.

Adapter case

5.

Center case

6.

Intake sensor bracket

7.

Intake sensor

8.

Upper ventilator door motor

9.

Upper ventilator door rod

10. Upper ventilator door lever

11.

Filter cover

12.

In-cabin microfilter

13. Foot duct 1 RH

14.

Foot duct 2 RH

15.

Air mix door motor (Passenger side)

16. Heater & cooling unit case cover

17.

Evaporator pipe assembly

18.

O-ring

19. Evaporator

20.

Expansion valve

21.

Case packing

22. Grommet

23.

Cooler pipe grommet

24.

Drain hose

25. Heater & cooling unit case RH

26.

Air mix door (Slide door)

27.

Heater pipe support

28. Heater pipe grommet

29.

Heater & cooling unit case LH

30.

Heater core

31. Heater pipe cover

32.

Foot duct 2 LH

33.

Foot duct 1 LH

34. Heater duct

35.

Aspirator

36.

Aspirator hose

37. Mode door motor

38.

Main link

39.

Rod link

40. Max. cool door link

41.

Ventilator door link

42.

Foot door link

43. Mode door lever

44.

Defroster door link

45.

Ventilator door lever

46. Foot door lever

47.

Defroster door lever

48.

Max. cool door lever

JPIIA0454GB