содержание .. 200 201 202 203 ..

Nissan Murano. Manual - part 202

BR-18

< PERIODIC MAINTENANCE >

REAR DISC BRAKE

REAR DISC BRAKE

BRAKE PAD

BRAKE PAD : Inspection and Adjustment

INFOID:0000000009722311

INSPECTION

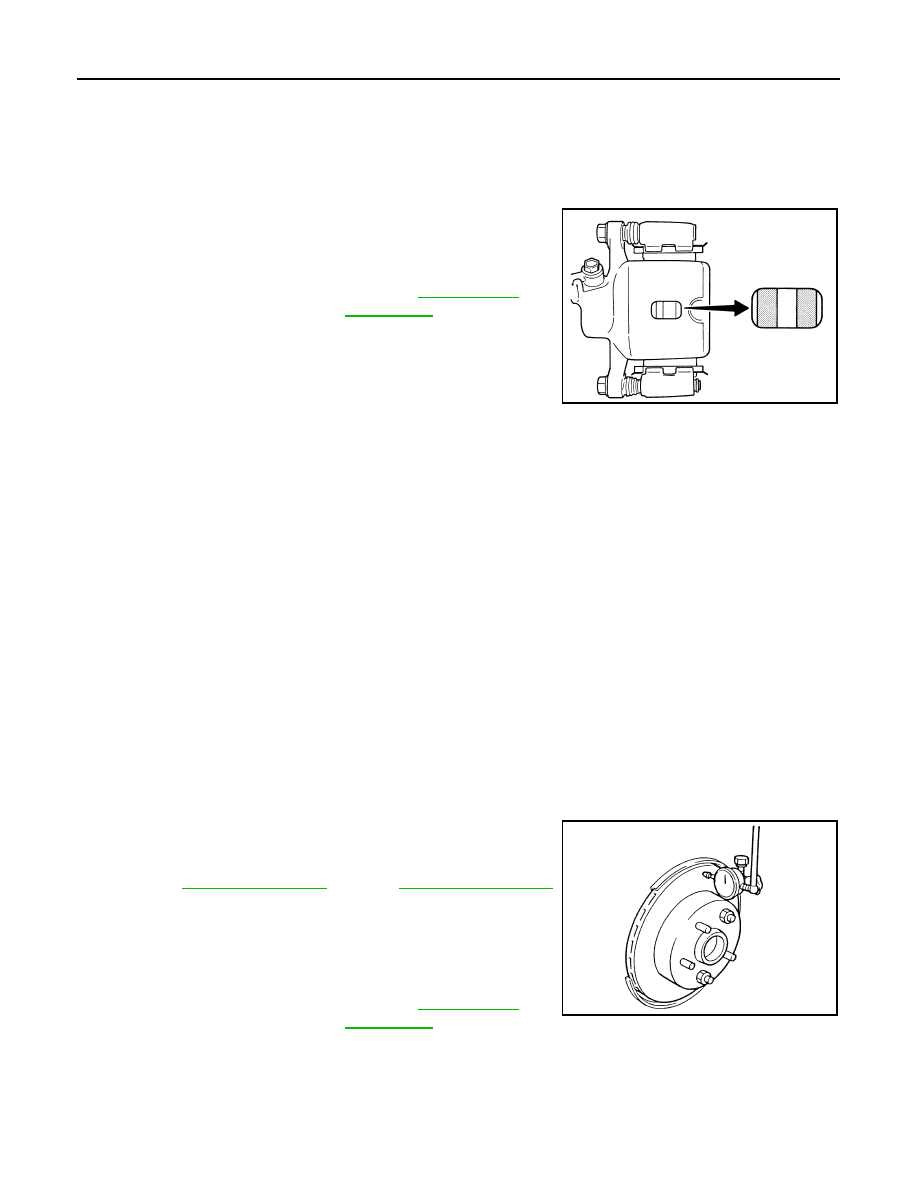

Check brake pad wear thickness from an inspection hole on cylinder

body. Check using a scale if necessary.

ADJUSTMENT

CAUTION:

• Burnish contact surfaces between pads according to the following procedure after refinishing or

replacing pads, or if a soft pedal occurs at very low mileage.

• Be careful of vehicle speed because the brake does not operate firmly/securely until pads and disc

rotor are securely fitted.

• Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1.

Drive vehicle on straight, flat road.

2.

Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3.

Drive without depressing brake for a few minutes to cool the brake.

4.

Repeat steps 1 to 3 until pad and disc rotor are securely fitted.

DISC ROTOR

DISC ROTOR : Inspection and Adjustment

INFOID:0000000009722312

INSPECTION

Appearance

Check surface of disc rotor for uneven wear, cracks, and serious damage. Replace if there are any abnormal

conditions.

Runout

1.

Fix the disc rotor to the wheel hub and bearing assembly with

wheel nuts (2 points at least).

2.

Check the wheel bearing axial end play before the inspection.

Refer to

(AWD).

3.

Inspect the runout with a dial gauge to measured at 10 mm (0.39

in) inside the disc edge.

4.

Find the installation position with a minimum runout by shifting the disc rotor-to-wheel hub and bearing

assembly installation position by one hole at a time if the runout exceeds the limit value.

5.

Refinish the disc rotor if the runout is outside the limit even after performing the above operation. [When

refinishing, use the Pro-Cut PEM On-Car brake Lathe (Tool No. 38-PFM90.5) or equivalent.]

CAUTION:

Limit

Wear thickness

: Refer to

.

BRA0010D

Limit

Runout

: Refer to

.

SBR019B