содержание .. 1358 1359 1360 1361 ..

Nissan Murano. Manual - part 1360

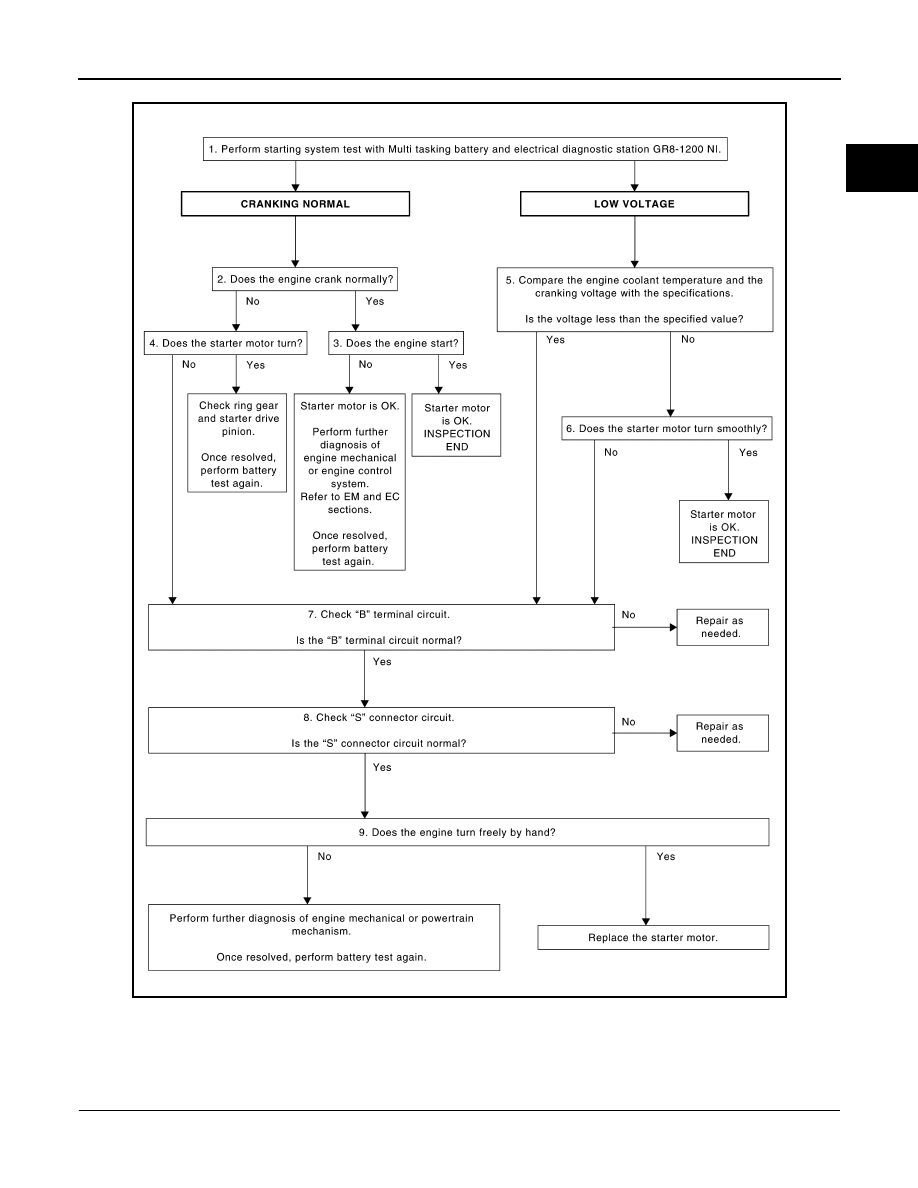

DIAGNOSIS AND REPAIR WORK FLOW

STR-3

< BASIC INSPECTION >

C

D

E

F

G

H

I

J

K

L

M

A

STR

N

P

O

OVERALL SEQUENCE

DETAILED FLOW

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter motor and alternator test segments must be

done as a set from start to finish.

1.

DIAGNOSIS WITH MULTITASKING BATTERY AND ELECTRICAL DIAGNOSTIC STATION GR8-1200 NI

JMBIA4453GB