содержание .. 730 731 732 733 ..

Nissan X-Trail 32. Manual - part 732

SYSTEM

EC-57

< SYSTEM DESCRIPTION >

[MR20DD]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

• When deceleration (accelerator pedal ON

→

OFF), ECM controls the engine speed by optimizing throttle

opening to minimize shift shock and exhaust gas emission.

COOLING FAN CONTROL

COOLING FAN CONTROL : System Description

INFOID:0000000010775041

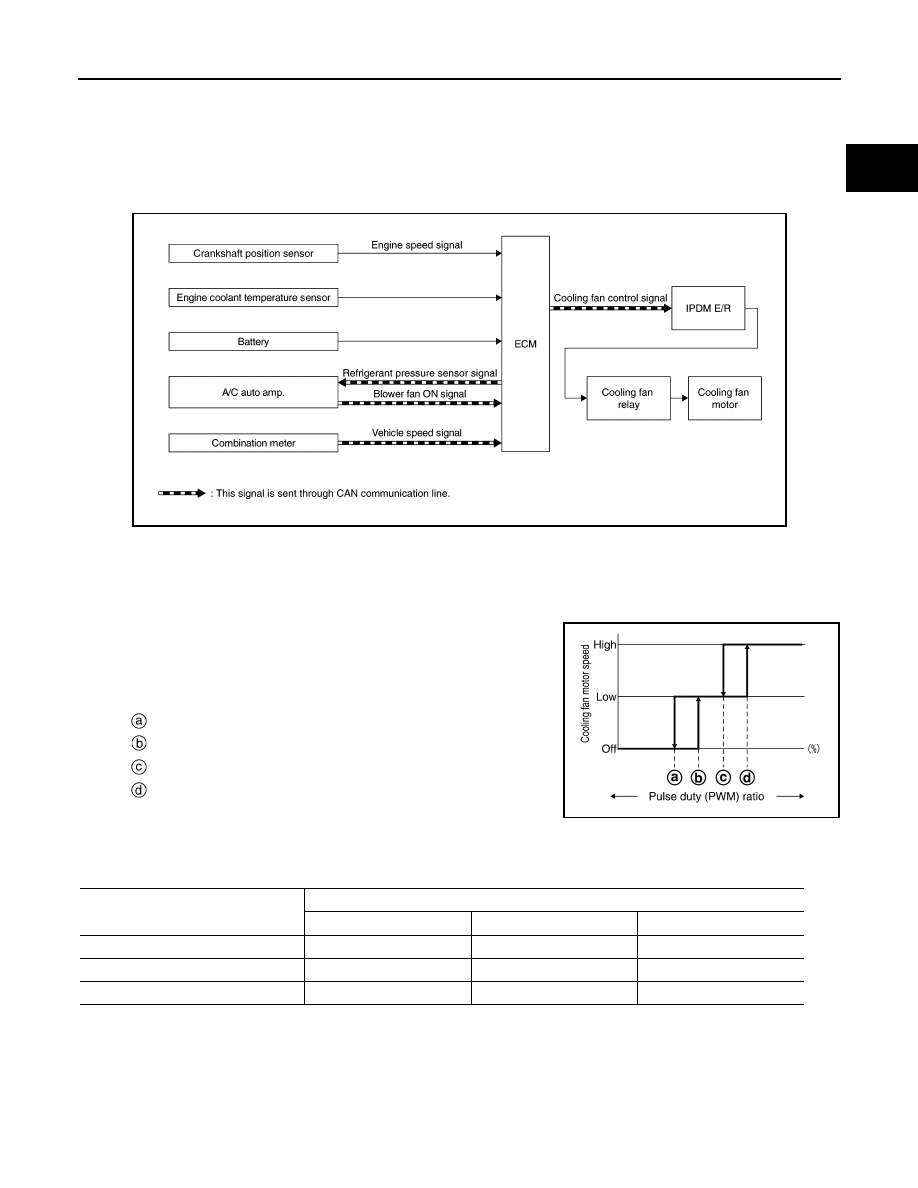

System Diagram

SYSTEM DESCRIPTION

ECM controls cooling fan speed corresponding to vehicle speed, engine coolant temperature, refrigerant pres-

sure, air conditioner ON signal. Then control system has 3-step control [ HIGH/LOW/OFF ].

Cooling Fan Operation

ECM transmits a pulse duty (PWM) signal to IPDM E/R.

IPDM E/R has threshold value to the pulse duty (PWM) signal and

operates cooling fan motor with three phases of [HI (high-speed) /

LOW (low-speed) /OFF].

Cooling Fan Relay Operation

The ECM controls cooling fan relays in IPDM E/R through CAN communication line.

INTAKE VALVE TIMING CONTROL

JSBIA5006GB

: Less than 30% (OFF

←

low-speed)

: More than 40% (OFF

→

low-speed)

: Less than 50% (low-speed

←

high-speed)

: More than 60% (low-speed

→

high-speed)

JSBIA5007GB

Cooling fan speed

Cooling fan relay

1

2

3

Stop (OFF)

OFF

OFF

OFF

Low (LOW)

OFF

ON

OFF

High (HI)

ON

OFF

ON