содержание .. 706 707 708 709 ..

Nissan X-Trail 32. Manual - part 708

ELECTRIC CONTROLLED COUPLING

DLN-243

< UNIT DISASSEMBLY AND ASSEMBLY >

[REAR FINAL DRIVE: R145]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

Disassembly and Assembly

INFOID:0000000011008626

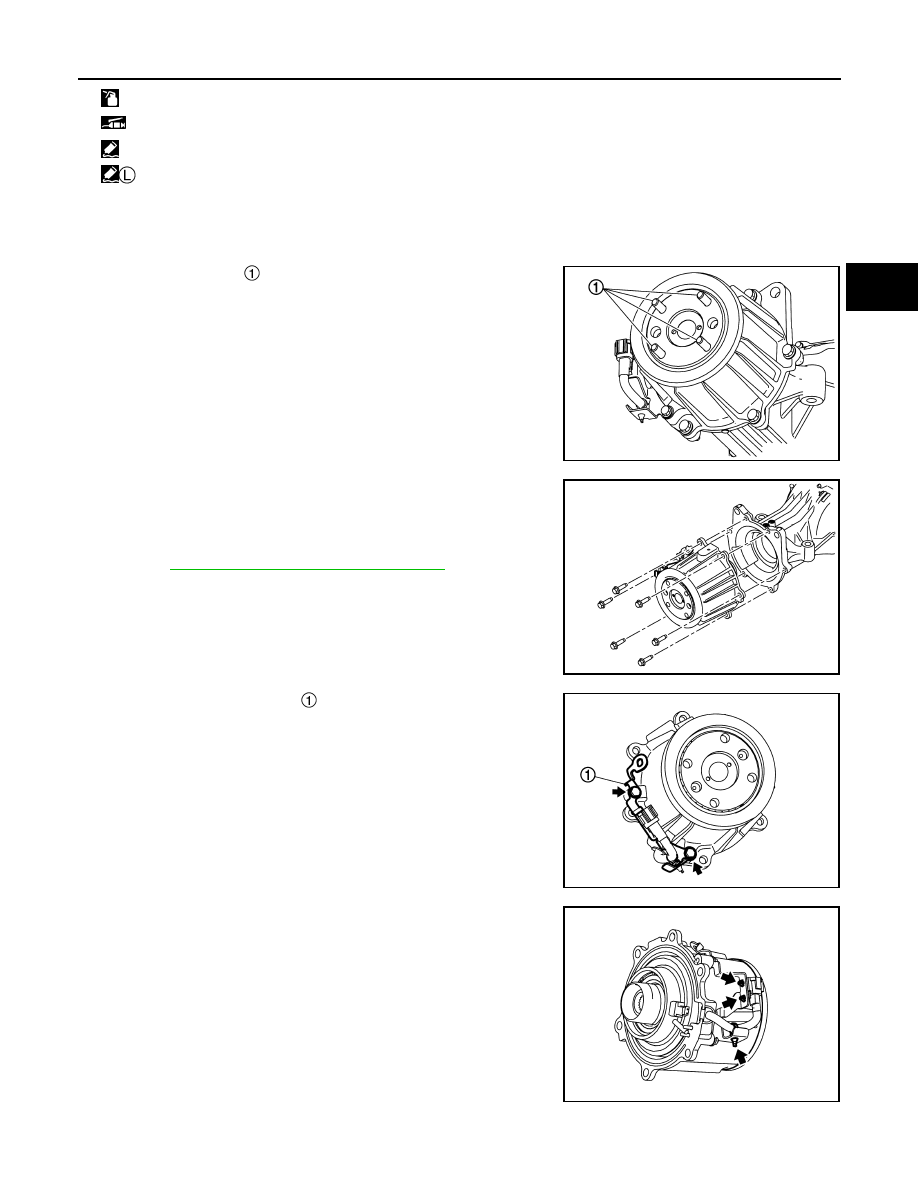

DISASSEMBLY

1.

Remove stud bolts

.

2.

Remove electric controlled coupling assembly from final drive

assembly.

3.

Remove wave spring.

4.

Remove drive pinion oil seal from the inside of gear carrier.

Refer to

DLN-258, "Disassembly and Assembly"

CAUTION:

When removing electric controlled coupling, replace drive

pinion oil seal.

5.

Remove connector bracket

from electric controlled coupling.

6.

Separate band clip and connector clip from connector bracket.

ASSEMBLY

*: Apply anti-corrosion oil.

: Apply multi purpose grease.

: Apply Genuine Liquid Gasket, Three Bond 1217 or equivalent.

: Apply Genuine High Strength Thread Locking Sealant, Loctite 270 or equivalent.

JSDIA5282ZZ

JSDIA5250ZZ

JSDIA5234ZZ

JSDIA5241ZZ