содержание .. 338 339 340 341 ..

Nissan X-Trail 32. Manual - part 340

DAS

CAMERA AIMING ADJUSTMENT

DAS-101

< BASIC INSPECTION >

[DRIVER ASSISTANCE SYSTEM]

C

D

E

F

G

H

I

J

K

L

M

B

N

P

A

• Notice that the cross of the target is horizontal and vertical.

>> Proceed to

DAS-101, "Work Procedure (Target Setting)"

Work Procedure (Target Setting)

INFOID:0000000010917462

CAUTION:

• Be sure to place the target correctly according to work procedures because the system may not

operate normally.

• Perform this operation in a horizontal position where there is a clear view for 5 m (16.4 ft) forward

and 3 m (9.84 ft) wide.

• Place the target in a well-lighted location. (Poor lighting may make it hard to adjust.)

• The target may not be detected when there is a light source within 1.5 m (4.92 ft) from either side and

within 1 m (3.28 ft) upward/downward from the target.

• Check the location of the sun. (Sunlight should not shine directly on the front of the vehicle.)

• The target may not be detected when there is the same pattern of black and white as the target when

the pattern is within 1 m (3.28 ft) from either side and upward/downward position from the target. (It

is desirable that the vehicle is positioned on the opposite side of a single-color wall.)

1.

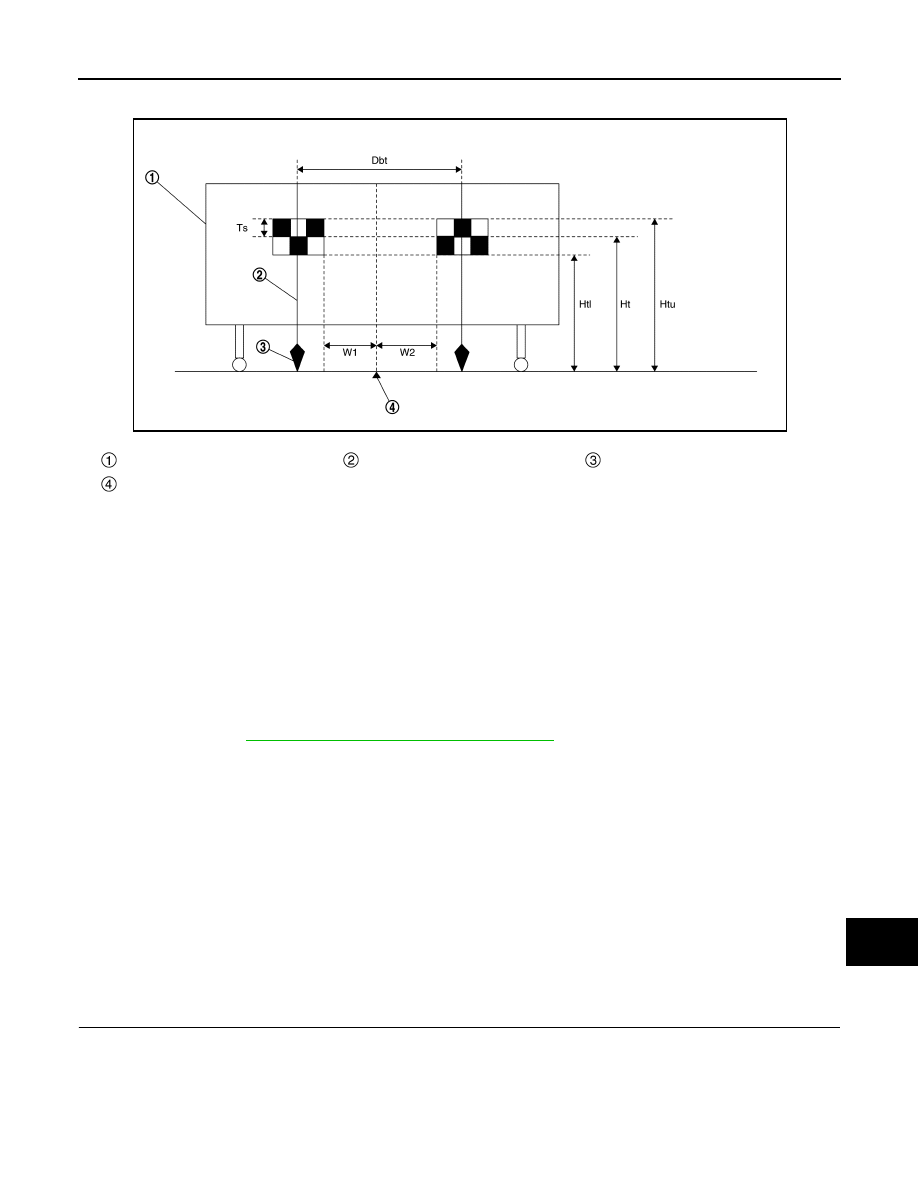

TARGET SETTING

Board

String

Cone

Center between two targets

Side of a target (Ts)

: 120 mm (4.72 in)

Height of a target lower end (Hti)

: 1180 mm (46.46 in)

Height of a target center (Ht)

: 1300 mm (51.18 in)

Height of a target upper end (Htu)

: 1420 mm (55.91 in)

Width between a right target cen-

ter from a left target center (Dbt)

: 720 mm (28.35 in)

W1

: 180 mm (7.09 in)

W2

: 180 mm (7.09 in)

JSOIA1661ZZ