содержание .. 2063 2064 2065 2066 ..

Nissan X-Trail 32. Manual - part 2065

TM-218

< UNIT DISASSEMBLY AND ASSEMBLY >

[6MT: RS6F52A]

FINAL DRIVE

4.

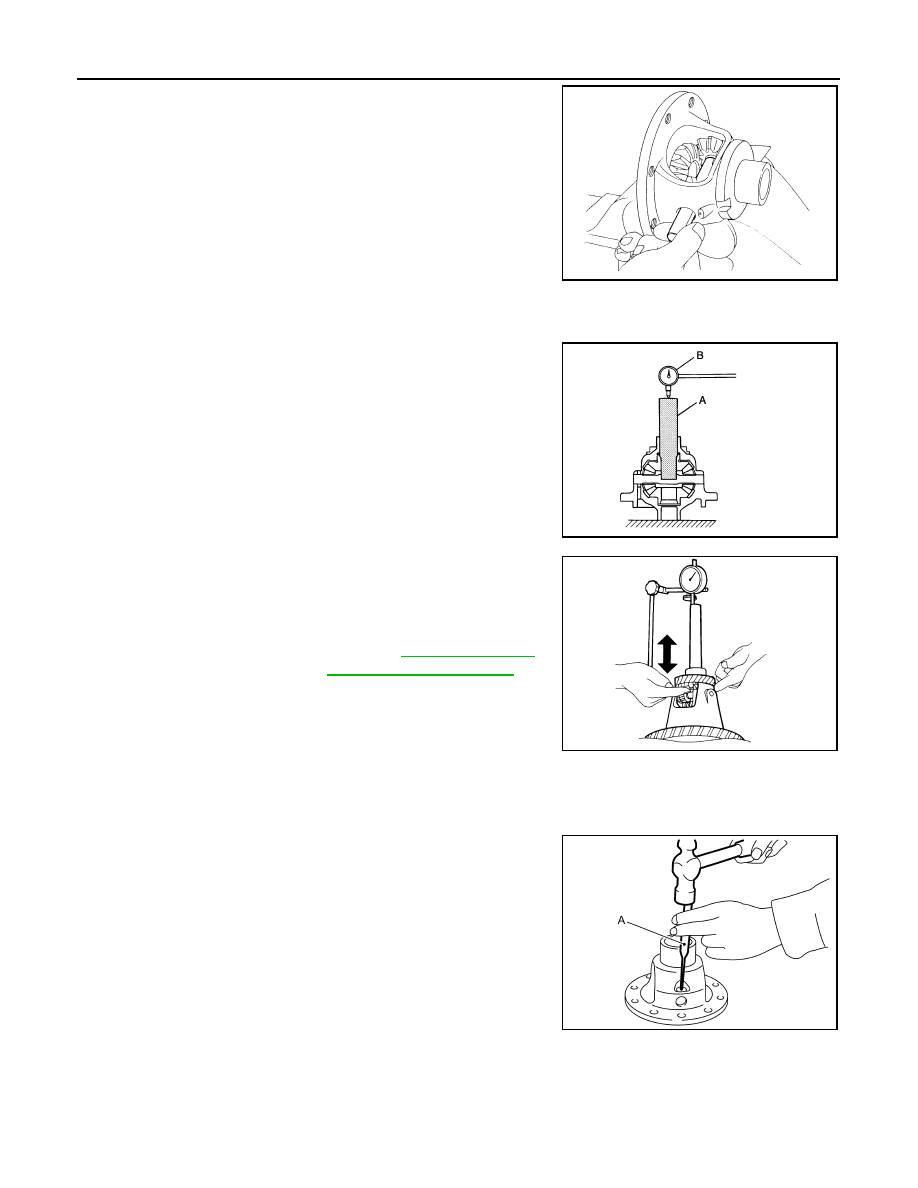

Insert pinion mate shaft into differential case.

CAUTION:

Be sure not to damage pinion mate thrust washers.

5.

Measure the end play of side gears, as per the following procedure. Then select side gear thrust washer.

a.

Put differential case vertically so that its side gear to be measured faces upward.

b.

Place the drift (A) (SST: ST15243000) and a dial indicator (B)

onto side gear.

c.

Move side gears up and down to measure the clearance and

select side gear thrust washer so that it satisfies the standard

value. For selecting side gear thrust washer, refer to the latest

parts information.

CAUTION:

• There should be no resistance and gears should rotate

freely.

• Place differential case upside down. Measure the end play for opposite side gears likewise

securely.

• Only one thrust washer can be selected.

6.

Install retaining pin into pinion mate shaft using a pin punch (A)

(commercial service tool).

CAUTION:

Never reuse retaining pin.

MTK0132D

JPDIC0360ZZ

Allowable Clearance be-

tween side gear and dif-

ferential case with thrust

washer

: Refer to

.

SMT611A

JSDIA6497ZZ