содержание .. 2059 2060 2061 2062 ..

Nissan X-Trail 32. Manual - part 2061

TM-202

< UNIT DISASSEMBLY AND ASSEMBLY >

[6MT: RS6F52A]

MAINSHAFT AND GEAR

3.

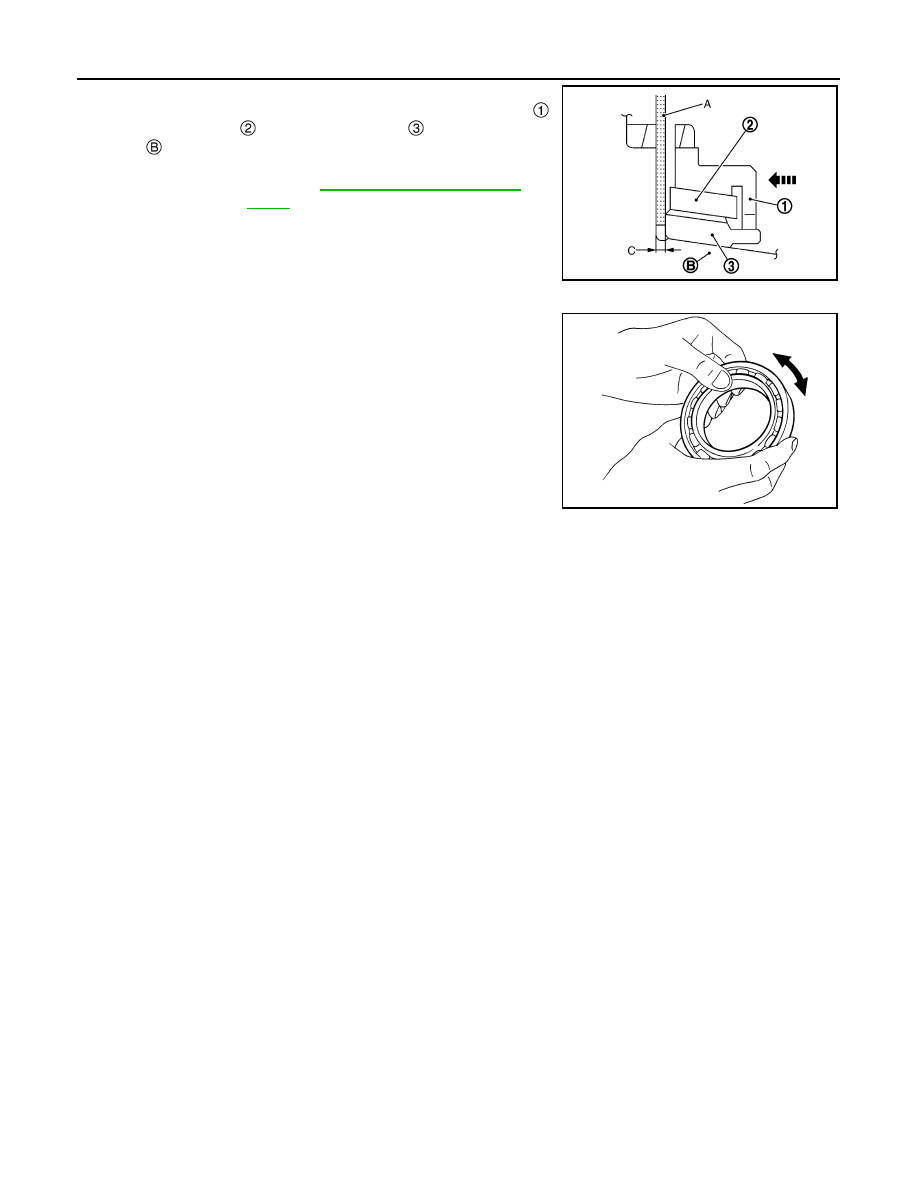

Measure the clearance (C) at 2 points or more diagonally oppo-

site using a feeler gauge (A) when pressing outer baulk ring

,

synchronizer cone

, and inner baulk ring

toward gear taper

cone

. And then calculate mean value.

BEARING

Check for bearing damage and rough rotation. If necessary, replace

with a new one.

Clearance (C)

: Refer to

JPDIC0035ZZ

MTF0041D