содержание .. 2058 2059 2060 2061 ..

Nissan X-Trail 32. Manual - part 2060

TM-198

< UNIT DISASSEMBLY AND ASSEMBLY >

[6MT: RS6F52A]

MAINSHAFT AND GEAR

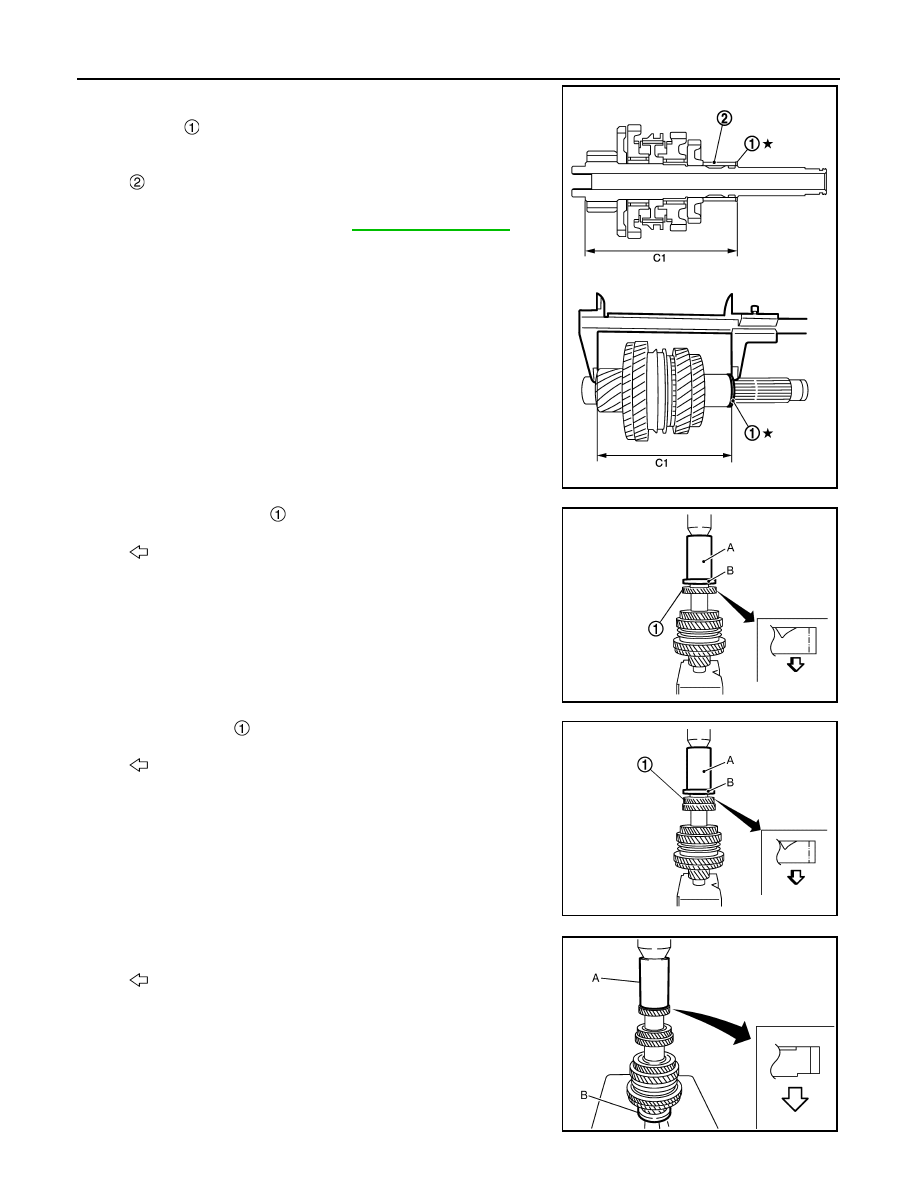

11. Select 4th main gear adjusting shim so that dimension (C1) sat-

isfies the standard value below and install 4th main gear adjust-

ing shim

onto mainshaft. For selecting 4th main gear

adjusting shim, refer to the latest parts information.

CAUTION:

Only one adjusting shim can be selected.

12. Press-fit 4th main gear

using the drifts (A and B).

CAUTION:

• Be careful with the orientation of 4th main gear.

• Never reuse 4th main gear.

13. Press-fit 5th main

gear using the drifts (A and B).

CAUTION:

• Be careful with the orientation of 5th main gear.

• Never reuse 5th main gear.

14. Install 5th-6th mainshaft spacer.

15. Press-fit 6th main gear using the drifts (A and B).

CAUTION:

• Be careful with the orientation of 6th main gear.

• Never reuse 6th main gear.

: 3rd-4th mainshaft spacer

Dimension (C1)

: Refer to

JPDIC0359ZZ

: Transaxle front side

A

: Drift (SST: ST33200000)

B

: Drift (SST: ST30901000)

JSDIA6506ZZ

: Transaxle front side

A

: Drift (SST: ST33200000)

B

: Drift (SST: ST30901000)

JSDIA6507ZZ

: Transaxle front side

A

: Drift (SST: ST33200000)

B

: Drift (SST: ST30901000)

JPDIC0372ZZ