содержание .. 1612 1613 1614 1615 ..

Nissan X-Trail 32. Manual - part 1614

MWI-138

< DTC/CIRCUIT DIAGNOSIS >

FUEL LEVEL SENSOR SIGNAL CIRCUIT

2.

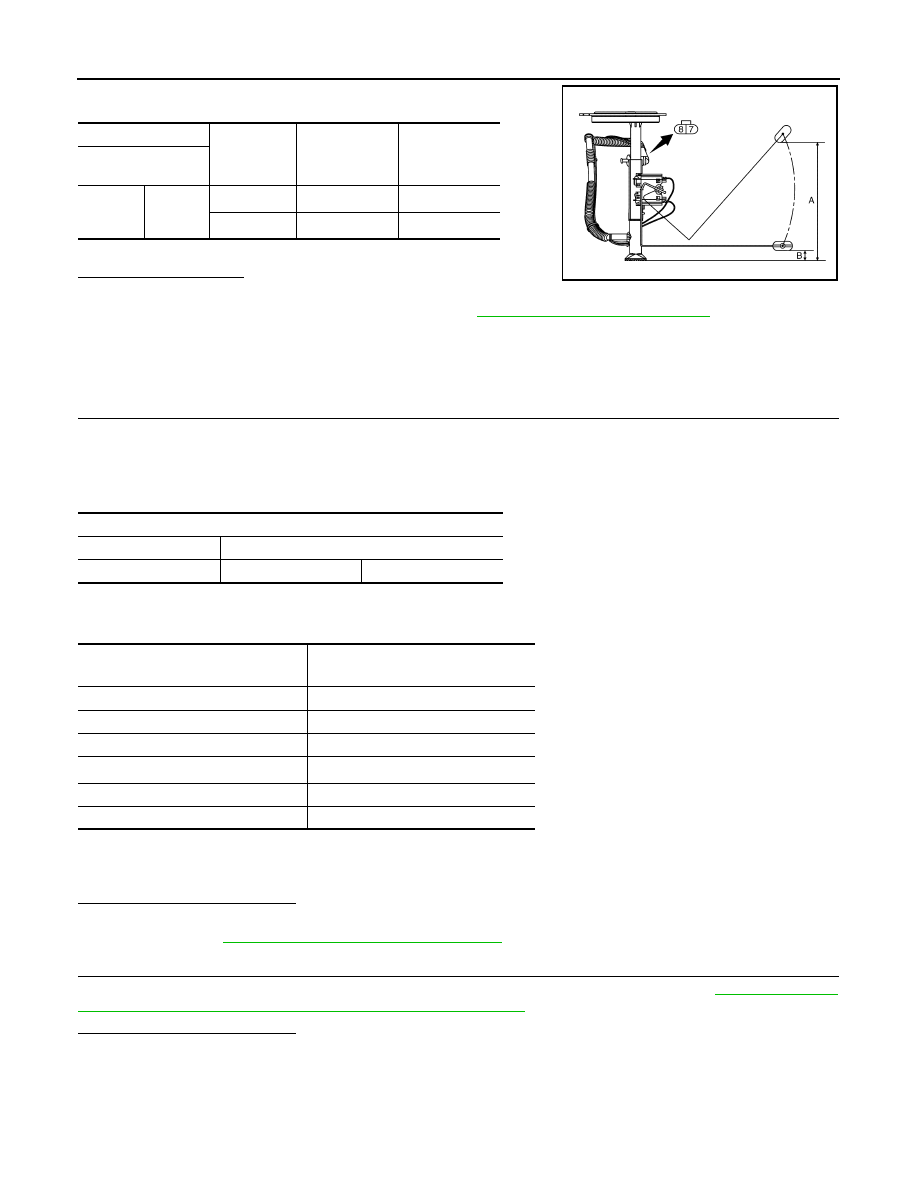

Check the resistance between fuel level sensor unit (sub).

*: When float rod is contact with stopper.

Is inspection result OK?

YES

>> INSPECTION END

NO

>> Replace fuel level sensor unit (sub). Refer to

FL-40, "Removal and Installation"

.

R9M

R9M : Component Function Check

INFOID:0000000010785100

1.

PERFORM COMPONENT FUNCTION CHECK (1)

1.

Turn ignition switch OFF.

2.

Disconnect fuel level sensor unit and fuel pump connector.

3.

Connect variable resistor between harness connector terminals located on the vehicle side of the fuel

level sensor unit.

4.

Set variable resistor according to the resistance value shown in the following table and turn ignition switch

ON.

*1: Reference resistance values used when the combination meter judges the indication position of the

fuel gauge.

*2: The inspection of 1/4 is not required.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Refer to

MWI-139, "R9M : Diagnosis Procedure"

.

2.

PERFORM COMPONENT FUNCTION CHECK (2)

Check the fuel level sensor unit and fuel pump, and fuel level sensor unit (sub). Refer to

Component Inspection [Fuel Level Sensor Unit (Main and Sub)]"

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace malfunctioning parts.

Terminals

Condition

Resistance (

Ω

)

(Approx.)

Height [mm (in)]

Fuel level sensor unit

(sub)

7

8

Full

*

(A)

6

204.9 (8.07)

Empty

*

(B)

141

16.8 (0.661)

JSNIA6747ZZ

Fuel level sensor unit

Connector

Terminals

B130

5

6

Resistance (

Ω

)

*1

(Approx.)

Fuel gauge indication position

Less than 93

Full

140

3/4

186

1/2

—

*2

1/4

255

1/8

More than 278

Empty