содержание .. 1569 1570 1571 1572 ..

Nissan X-Trail 32. Manual - part 1571

MA-74

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

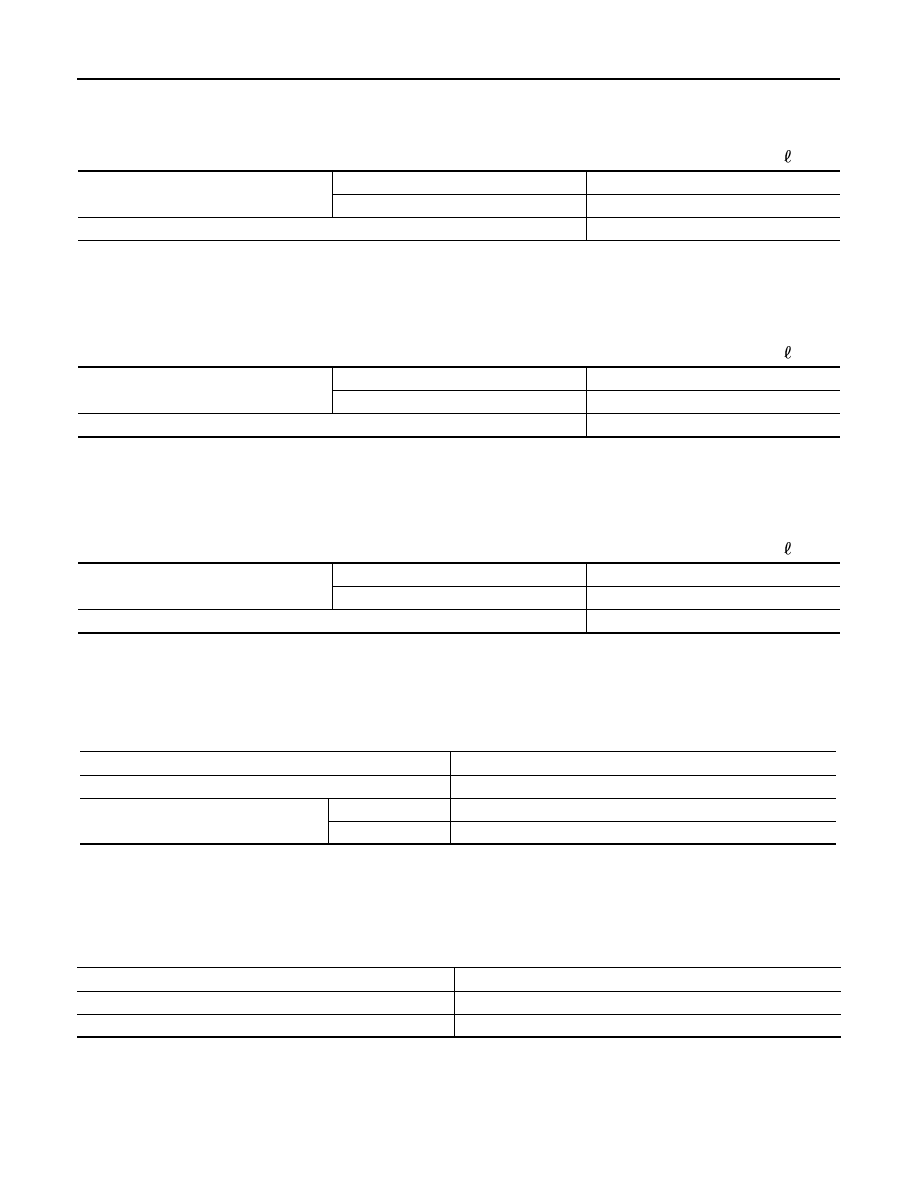

ENGINE OIL (MR20DD) : Periodical Maintenance Specification

INFOID:0000000011009249

ENGINE OIL CAPACITY (APPROXIMATE)

Unit:

(lmp qt)

ENGINE OIL (QR25DE)

ENGINE OIL (QR25DE) : Periodical Maintenance Specification

INFOID:0000000011009253

ENGINE OIL CAPACITY (APPROXIMATE)

Unit:

(lmp qt)

ENGINE OIL (R9M)

ENGINE OIL (R9M) : Periodical Maintenance Specification

INFOID:0000000010828056

ENGINE OIL CAPACITY (APPROXIMATE)

Unit:

(lmp qt)

SPARK PLUG (MR20DD)

SPARK PLUG (MR20DD) : Spark Plug

INFOID:0000000011009242

SPARK PLUG

Unit: mm (in)

SPARK PLUG (QR25DE)

SPARK PLUG (QR25DE) : Spark Plug

INFOID:0000000011009247

SPARK PLUG

Unit: mm (in)

ROAD WHEEL

ROAD WHEEL : Road Wheel

INFOID:0000000010828077

ALUMINUM WHEEL

Drain and refill

With oil filter change

3.8 (3-3/8)

Without oil filter change

3.6 (3-1/8)

Dry engine (Overhaul)

4.4 (3-7/8)

Drain and refill

With oil filter change

4.6 (4)

Without oil filter change

4.3 (3-3/4)

Dry engine (Overhaul)

5.3 (4-5/8)

Drain and refill

With oil filter change

5.5 (4-7/8)

Without oil filter change

5.1 (4-1/2)

Dry engine (Overhaul)

6.6 (5-7/8)

Make

NGK

Standard type

DILKAR7D11H

Gap (Nominal)

Standard

1.1 (0.043)

Limit

1.3 (0.051)

Make

DENSO

Standard type

FXE20HE11

Spark plug gap (Nominal)

1.1 (0.043)