содержание .. 1263 1264 1265 1266 ..

Nissan X-Trail 32. Manual - part 1265

FAX-52

< REMOVAL AND INSTALLATION >

[2WD]

FRONT DRIVE SHAFT

11. Remove drive shaft from wheel hub and bearing assembly.

CAUTION:

• Never place drive shaft joint at an extreme angle.

• Be careful not to overextend slide joint.

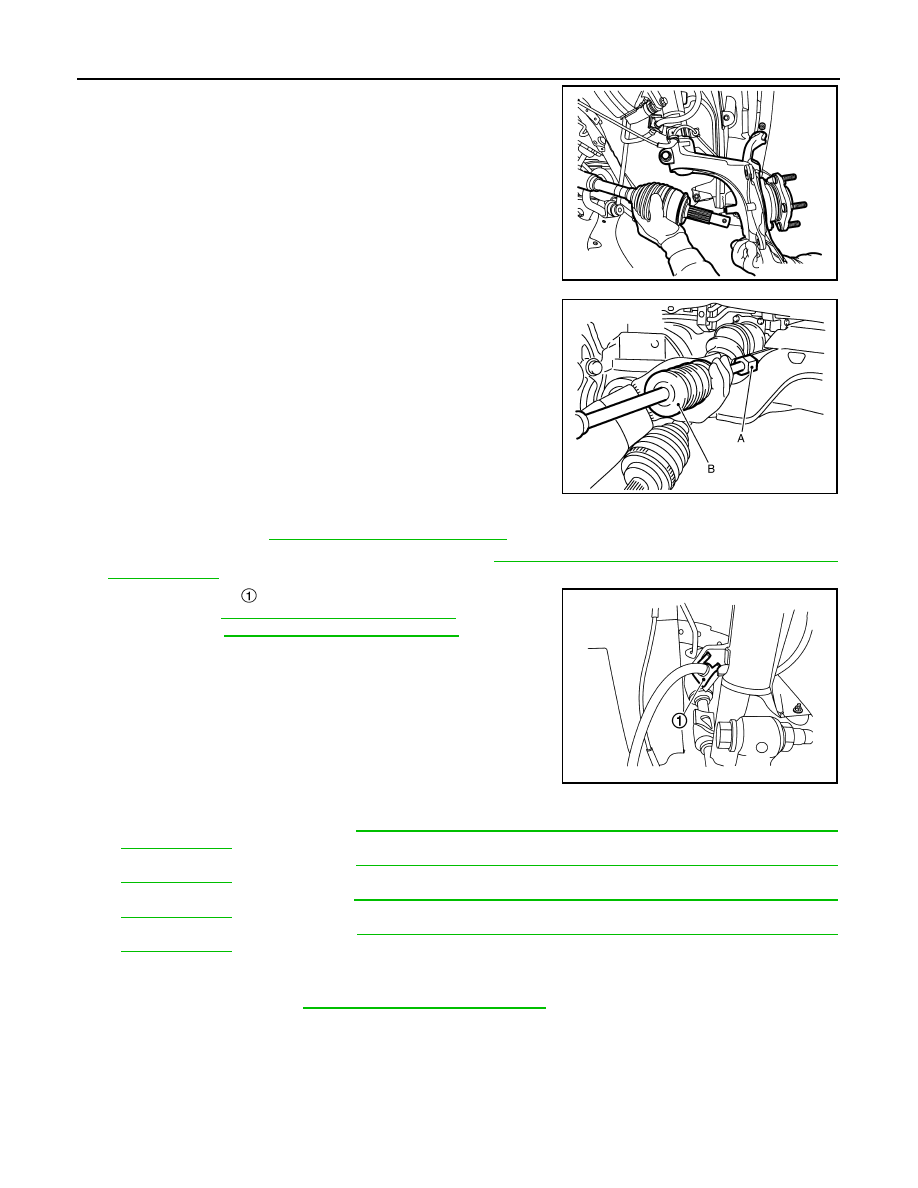

12. Remove drive shaft from transaxle assembly.

• Use the drive shaft attachment (A) (SST: KV40107500) and a

sliding hammer (B) (commercial service tool) while inserting

tip of the drive shaft attachment between housing and tran-

saxle assembly.

CAUTION:

• Never place drive shaft joint at an extreme angle when

removing drive shaft. Also be careful not to overextend

slide joint.

• Confirm that the circular clip is attached to the drive

shaft.

Right Side

1.

Remove tires. Refer to

WT-61, "Removal and Installation"

.

2.

Remove wheel sensor from steering knuckle. Refer to

BRC-212, "FRONT WHEEL SENSOR : Removal

3.

Remove lock plate

from strut assembly.

• LHD: Refer to

BR-24, "FRONT : Exploded View"

.

• RHD: Refer to

BR-88, "FRONT : Exploded View"

4.

Remove caliper assembly. Hang caliper assembly in a place where it will not interfere with work.

• LHD (1 PISTON TYPE): Refer to

BR-51, "BRAKE CALIPER ASSEMBLY (1 PISTON TYPE) : Removal

• LHD (2 PISTON TYPE): Refer to

BR-56, "BRAKE CALIPER ASSEMBLY (2 PISTON TYPE) : Removal

• RHD (1 PISTON TYPE): Refer to

BR-111, "BRAKE CALIPER ASSEMBLY (1 PISTON TYPE) : Removal

• RHD (2 PISTON TYPE): Refer to

BR-56, "BRAKE CALIPER ASSEMBLY (2 PISTON TYPE) : Removal

CAUTION:

Never depress brake pedal while brake caliper is removed.

5.

Remove disc rotor. Refer to

FAX-11, "Removal and Installation"

.

JSDIA5562ZZ

JPDIF0004ZZ

JSDIA3795ZZ