содержание .. 1065 1066 1067 1068 ..

Nissan X-Trail 32. Manual - part 1067

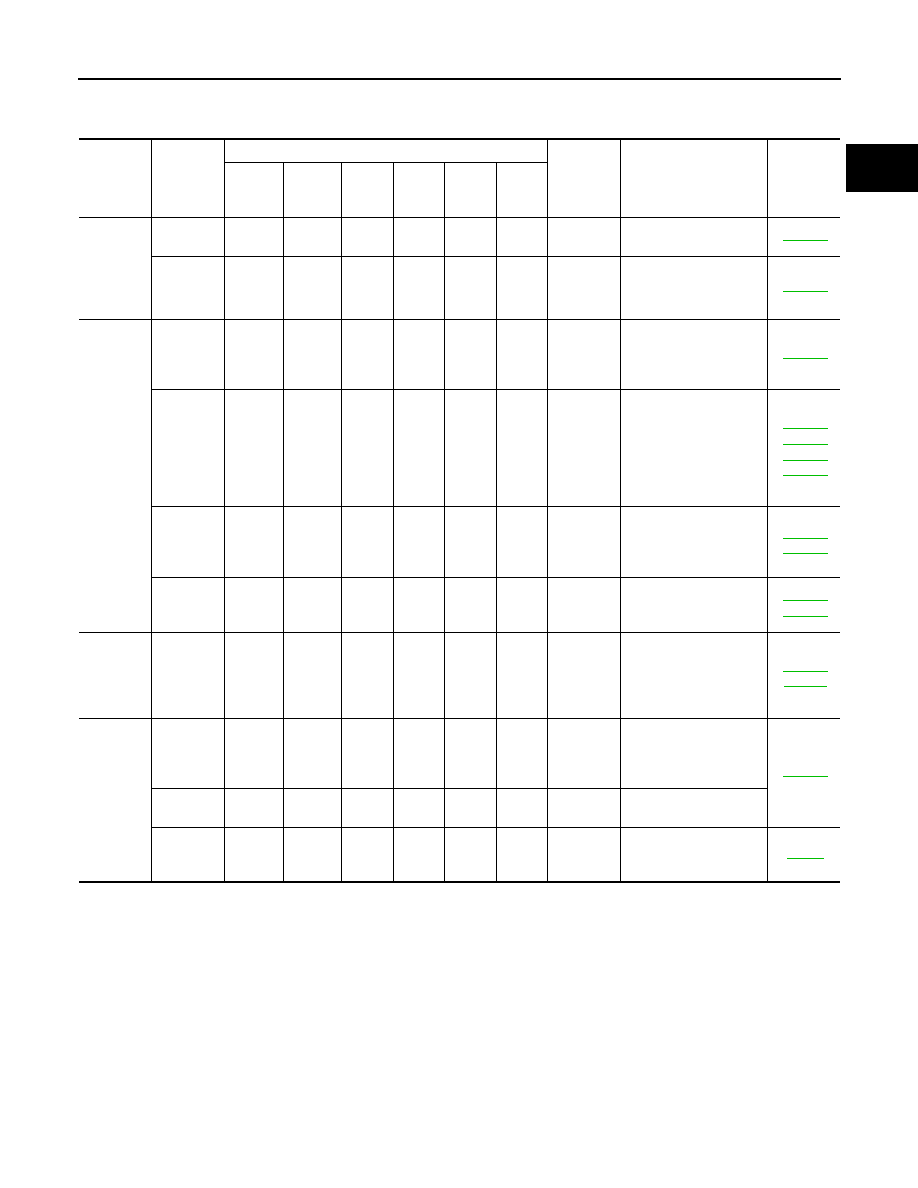

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

EM-165

< SYMPTOM DIAGNOSIS >

[QR25DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

4.

Check specified noise source.

If necessary, repair or replace these parts.

A: Closely related

B: Related

C: Sometimes related

—: Not related

Location

of noise

Type of

noise

Operating condition of engine

Source of

noise

Check item

Refer-

ence page

Before

warm-

up

After

warm-

up

When

start-

ing

When

idling

When

racing

While

driving

Top of en-

gine

Rocker

cover

Cylinder

head

Ticking or

clicking

C

A

—

A

B

—

Tappet

noise

Valve clearance

Rattle

C

A

—

A

B

C

Camshaft

bearing

noise

Camshaft journal oil

clearance

Camshaft runout

Crank-

shaft pul-

ley

Cylinder

block

(Side of

engine)

Oil pan

Slap or

knock

—

A

—

B

B

—

Piston pin

noise

Piston to piston pin oil

clearance

Connecting rod bushing

oil clearance

Slap or

rap

A

—

—

B

B

A

Piston

slap noise

Piston to cylinder bore

clearance

Piston ring side clear-

ance

Piston ring end gap

Connecting rod bend

and torsion

Knock

B

A

C

B

B

B

Connect-

ing rod

bearing

noise

Connecting rod bushing

oil clearance

Connecting rod bearing

oil clearance

Knock

B

A

—

A

B

C

Main bear-

ing noise

Main bearing oil clear-

ance

Crankshaft runout

Front of

engine

Front cov-

er

Tapping or

ticking

A

A

—

B

B

B

Timing

chain and

chain ten-

sioner

noise

Timing chain cracks

and wear

Timing chain tensioner

operation

Front of

engine

Squeak-

ing or fizz-

ing

A

B

—

B

B

B

Drive belt

(Sticking

or slip-

ping)

Drive belt deflection

Creaking

A

B

A

B

A

B

Drive belt

(Slipping)

Idler pulley bearing op-

eration

Squall

Creak

A

B

—

B

A

B

Water

pump

noise

Water pump operation