содержание .. 1064 1065 1066 1067 ..

Nissan X-Trail 32. Manual - part 1066

CAMSHAFT VALVE CLEARANCE

EM-161

< BASIC INSPECTION >

[QR25DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

1.

Remove camshaft. Refer to

2.

Remove valve lifters at the locations that are out of the standard.

3.

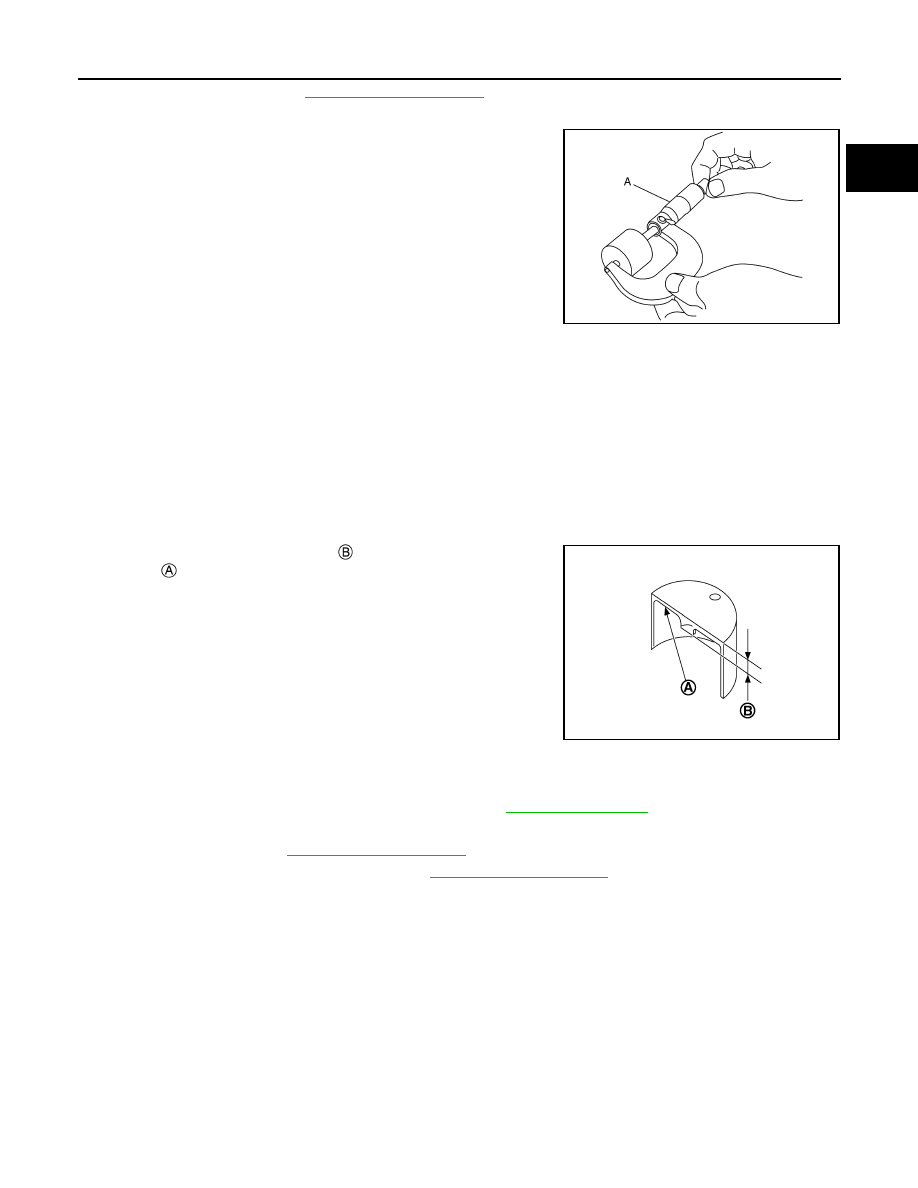

Measure the center thickness of the removed valve lifters with a

micrometer (A).

4.

Use the equation below to calculate valve lifter thickness for replacement.

• Thickness of new valve lifter

can be identified by stamp

mark

on the reverse side (inside the cylinder).

• Stamp mark “300” indicates 3.00 mm (0.1181 in) in thickness.

NOTE:

Available thickness of valve lifter: 26 sizes range 3.00 to 3.50 mm (0.1181 to 0.1378 in) in steps of 0.02

mm (0.0008 in) (when manufactured at factory). Refer to

5.

Install the selected valve lifter.

6.

Install camshaft. Refer to

7.

Install timing chain and related parts. Refer to

8.

Manually rotate crankshaft pulley a few rotations.

9.

Check that the valve clearances is within the standard. Refer to “INSPECTION”.

10. Install remaining parts in the reverse order of removal.

11. Warm up the engine, and check for unusual noise and vibration.

JSBIA2416ZZ

Valve lifter thickness calculation:

t = t

1

+ (C

1

– C

2

)

t

= Valve lifter thickness to be replaced

t

1

= Removed valve lifter thickness

C

1

= Measured valve clearance

C

2

= Standard valve clearance:

Intake

: 0.28 mm (0.011 in)

Exhaust

: 0.30 mm (0.012 in)

PBIC3196J