содержание .. 1051 1052 1053 1054 ..

Nissan X-Trail 32. Manual - part 1053

CYLINDER BLOCK

EM-109

< UNIT DISASSEMBLY AND ASSEMBLY >

[MR20DD]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

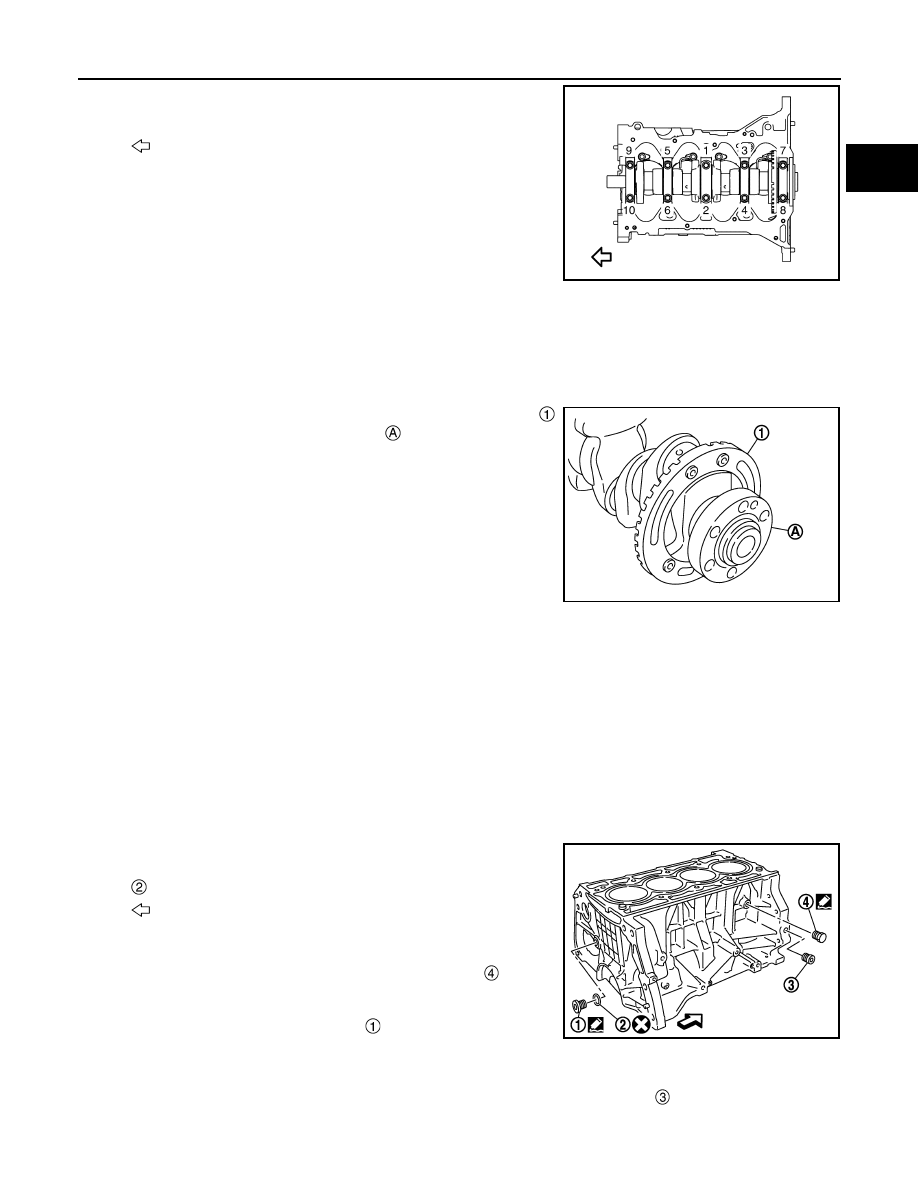

• Loosen and remove main bearing cap bolts in the order from

10 to 1 as shown in the figure.

• Use TORX socket.

11. Remove main bearing caps.

• Tap main bearing caps lightly with a plastic hammer for removal.

CAUTION:

Be careful not to damage the mounting surface.

12. Remove crankshaft.

CAUTION:

• Be careful not to damage or deform signal plate

mounted on rear end of crankshaft

.

• When setting crankshaft on a flat floor surface, use a

block of wood to avoid interference between signal plate

and the floor surface.

• Never remove signal plate unless it is necessary to do so.

NOTE:

When removing or installing signal plate, use TORX socket.

13. Pull rear oil seal out from rear end of crankshaft.

14. Remove main bearings and thrust bearings from cylinder block and main bearing caps.

CAUTION:

Identify installation positions, and store them without mixing them up.

ASSEMBLY

CAUTION:

Do not reuse O-rings or washers.

1.

Fully air-blow engine coolant and engine oil passages in cylinder block, cylinder bore and crankcase to

remove any foreign material.

CAUTION:

Use a goggles to protect your eye.

2.

Install each plug to cylinder block as shown in the figure.

CAUTION:

Do not reuse washer.

• Apply liquid gasket to the thread of water drain plug

.

Use Genuine Liquid Gasket (Three Bond 1215) or equiva-

lent.

• Apply sealant to the thread of plug

.

Use genuine high strength thread locking sealant (Three

Bond 1386B) or equivalent.

NOTE:

Do not apply liquid gasket or high strength thread locking sealant to the plug

.

• Tighten each plug as specified below.

: Engine front

JSBIA4604ZZ

PBIC3234J

: Washer

: Engine front

PBIC3999E