содержание .. 1052 1053 1054 1055 ..

Nissan X-Trail 32. Manual - part 1054

CYLINDER BLOCK

EM-113

< UNIT DISASSEMBLY AND ASSEMBLY >

[MR20DD]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

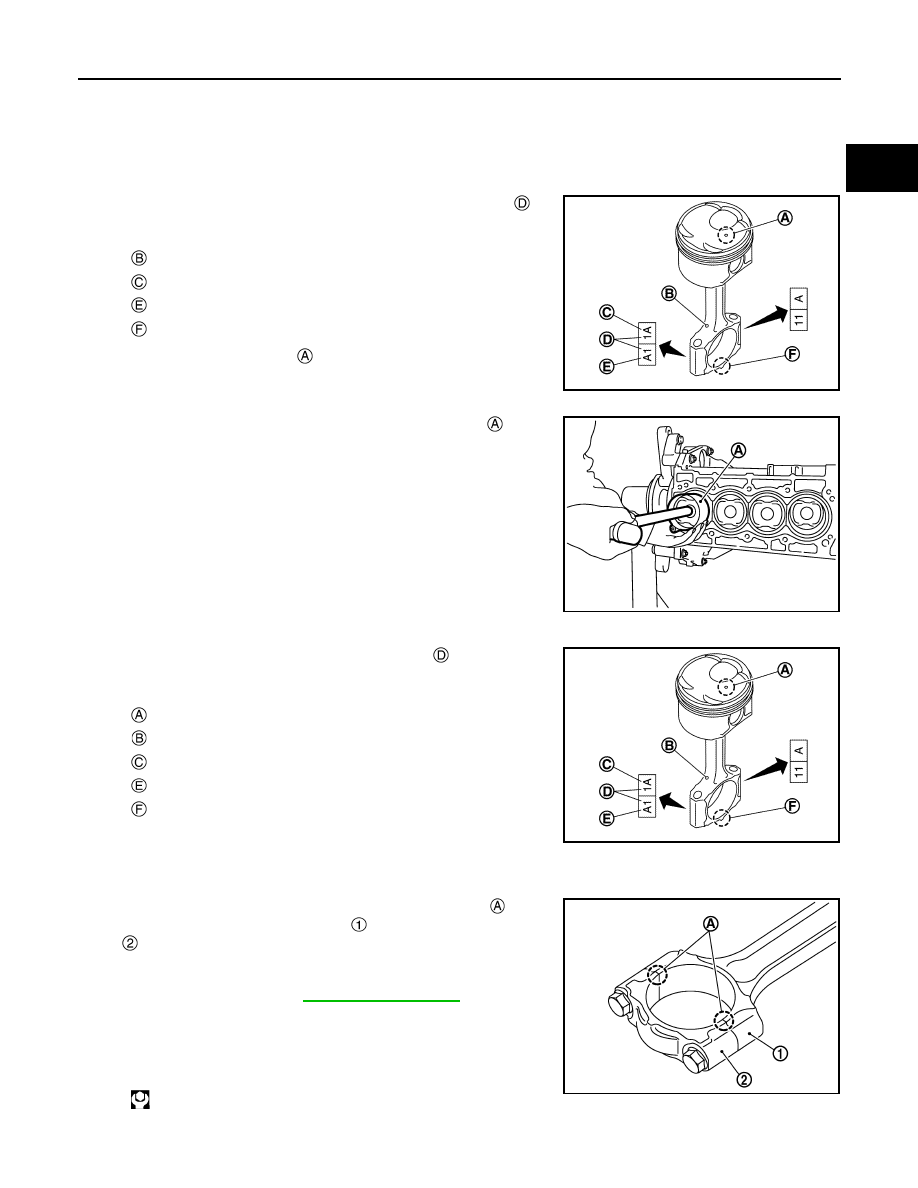

• Install the connecting rod bearings in the center of connecting rod and connecting rod cap as shown in

the figure. For service operation, the center position can be checked, visually.

10. Install piston and connecting rod assembly to crankshaft.

• Position crankshaft pin corresponding to connecting rod to be installed onto the bottom dead center.

• Apply new engine oil sufficiently to the cylinder bore, piston and crankshaft pin.

• Match the cylinder position with the cylinder number

on

connecting rod to install.

• Install so that front mark

on the piston head faces the front

of engine.

• Using a piston ring compressor [SST: EM03470000]

or suit-

able tool, install piston with the front mark on the piston head

facing the front of the engine.

CAUTION:

Be careful not to damage the cylinder wall and crankshaft

pin, resulting from an interference of the connecting rod

big end.

11. Install connecting rod cap.

• Match the stamped cylinder number marks

on connecting

rod with those on connecting rod cap to install.

12. Tighten connecting rod cap bolt with the following procedure:

CAUTION:

• Check that there is no gap in the thrust surface

of the

joint between connecting rod

and connecting rod cap

and that these parts are in the correct position. And

then, tighten the connecting rod cap bolts.

• If the connecting rod cap bolts are reused, measure the

outer diameter. Refer to

a.

Apply new engine oil to the threads and seats of connecting rod

cap bolts.

b.

Tighten connecting rod cap bolts.

c.

Completely loosen connecting rod cap bolts.

: Oil hole

: Management code

: Big end diameter grade

: Front mark (connecting rod cap)

JPBIA4434ZZ

PBIC3244J

: Front mark (piston)

: Oil hole

: Management code

: Big end diameter grade

: Front mark (connecting rod cap)

JPBIA4434ZZ

: 27.5 N·m (2.8 kg-m, 20 ft-lb)

PBIC3510J