содержание .. 1049 1050 1051 1052 ..

Nissan X-Trail 32. Manual - part 1051

CYLINDER HEAD

EM-101

< UNIT DISASSEMBLY AND ASSEMBLY >

[MR20DD]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

INSPECTION AFTER INSTALLATION

Inspection for Leakage

The following are procedures for checking fluids leakage, lubricates leakage, and exhaust gases leakage.

• Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to

MA-23, "Fluids and Lubricants"

.

• Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration.

• Warm up engine thoroughly to check there is no leakage of fuel, exhaust gases, or any oil/fluids including

engine oil and engine coolant.

• Bleed air from lines and hoses of applicable lines, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

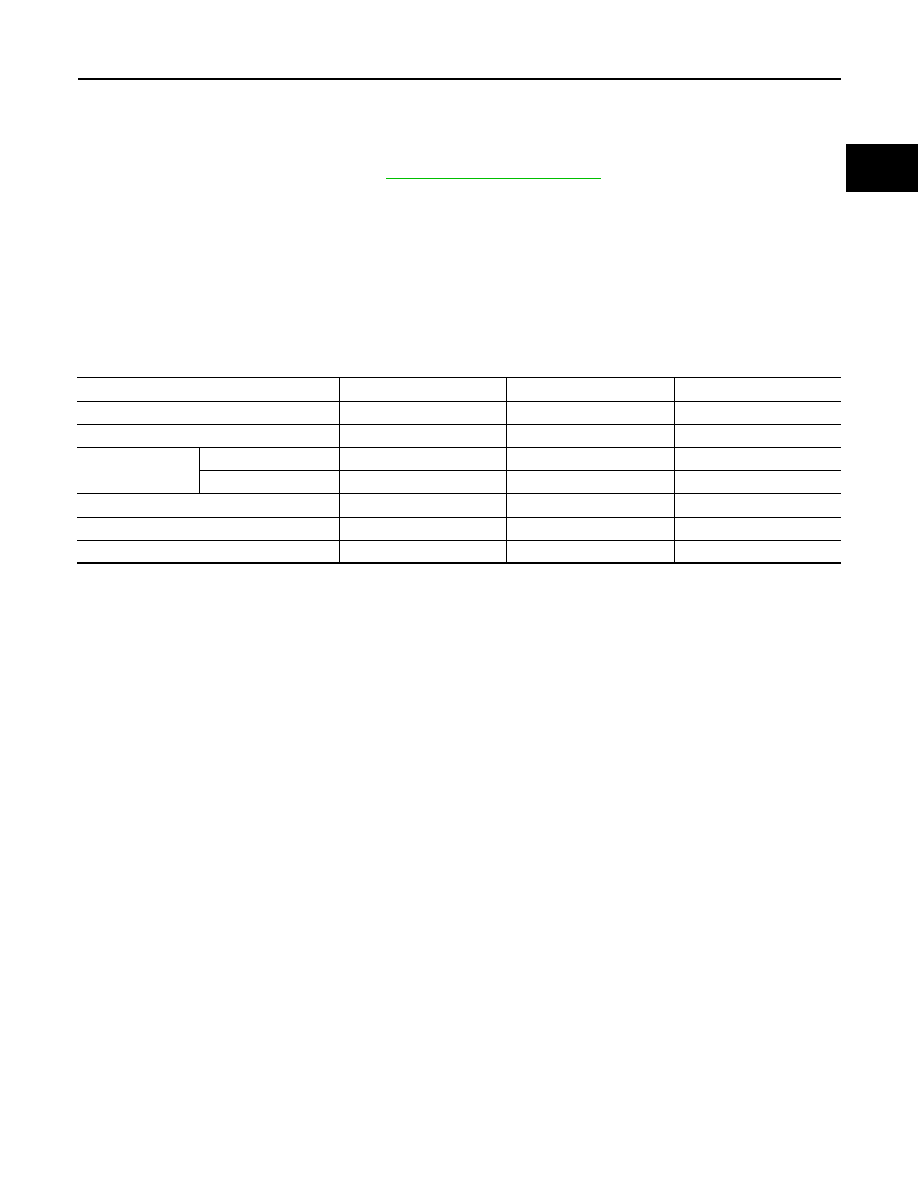

Summary of the inspection items:

*: Power steering fluid, brake fluid, etc.

Items

Before starting engine

Engine running

After engine stopped

Engine coolant

Level

Leakage

Level

Engine oil

Level

Leakage

Level

Transmission /

transaxle fluid

AT & CVT Models

Leakage

Level / Leakage

Leakage

MT Models

Level / Leakage

Leakage

Level / Leakage

Other oils and fluids*

Level

Leakage

Level

Fuel

Leakage

Leakage

Leakage

Exhaust gases

—

Leakage

—