содержание .. 1047 1048 1049 1050 ..

Nissan X-Trail 32. Manual - part 1049

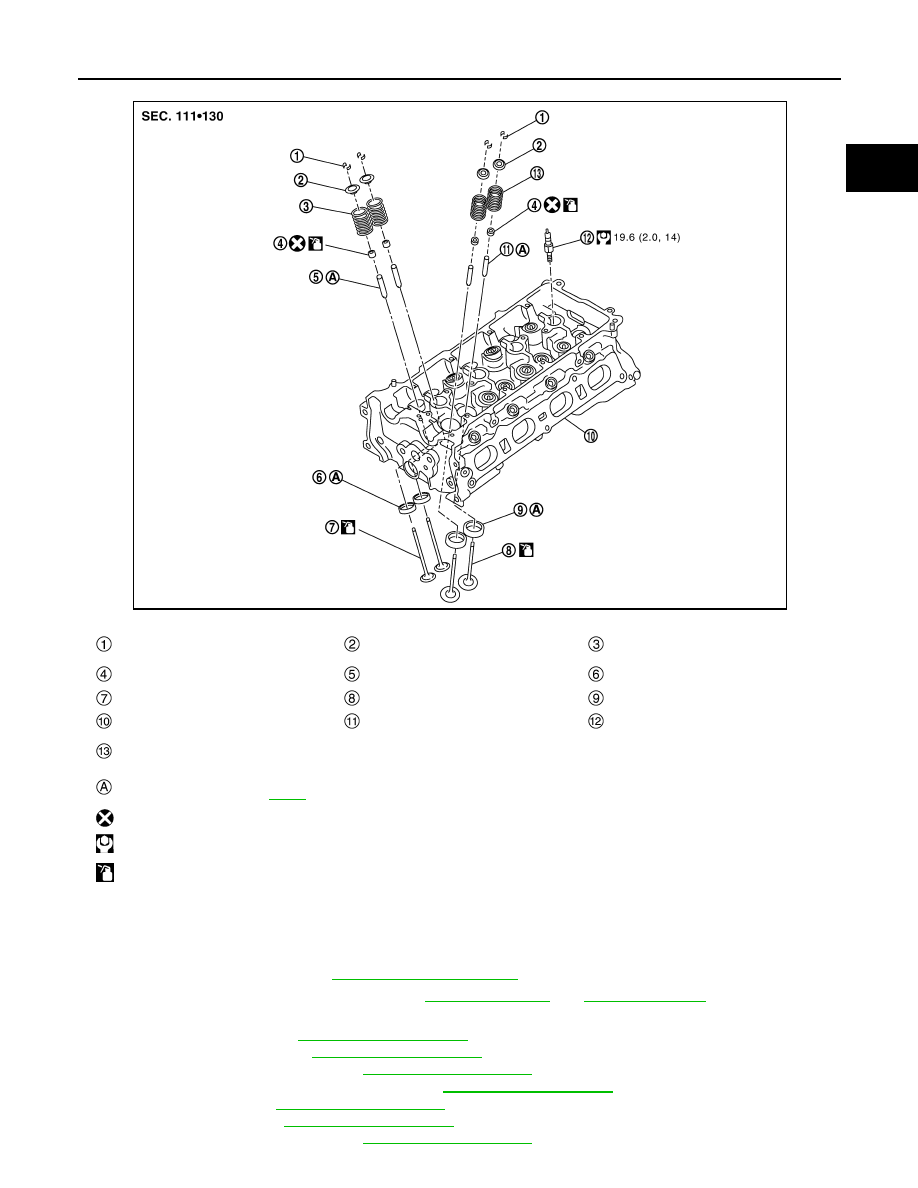

CYLINDER HEAD

EM-93

< UNIT DISASSEMBLY AND ASSEMBLY >

[MR20DD]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

Removal and Installation

INFOID:0000000010783726

REMOVAL

1.

Release fuel pressure. Refer to

2.

Drain engine coolant and engine oil. Refer to

3.

Remove the following components and related parts.

• Intake manifold: Refer to

• Exhaust manifold: Refer to

• High pressure fuel pump: Refer to

.

• Fuel tube and fuel injector assembly: Refer to

• Water outlet: Refer to

.

• Rocker cover: Refer to

• Front cover, timing chain: Refer to

.

Valve collet

Valve spring retainer

Valve spring

(with valve spring seat) (EXH)

Valve oil seal

Valve guide (EXH)

Valve seat (EXH)

Valve (EXH)

Valve (INT)

Valve seat (INT)

Cylinder head

Valve guide (INT)

Spark plug

Valve spring

(with valve spring seat) (INT)

Comply with the installation procedure

when tightening. Refer to

: Always replace after every disassembly.

: N·m (kg-m, ft-lb)

: Should be lubricated with oil.

JPBIA1753GB