содержание .. 1044 1045 1046 1047 ..

Nissan X-Trail 32. Manual - part 1046

CAMSHAFT

EM-81

< UNIT DISASSEMBLY AND ASSEMBLY >

[MR20DD]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

Removal and Installation

INFOID:0000000010783720

CAUTION:

The rotating direction in the text indicates all directions seen from the engine front.

REMOVAL

1.

Remove the following parts.

• Intake manifold: Refer to

• Rocker cover: Refer to

• Front cover and timing chain related parts: Refer to

NOTE:

Removal of oil pump drive related part is not necessary.

2.

Remove camshaft position sensor (PHASE) and exhaust valve timing control position sensor from cam-

shaft bracket.

CAUTION:

• Handle camshaft position sensor (PHASE) and exhaust valve timing control position sensor

carefully and avoid impacts.

• Never disassemble camshaft position sensor (PHASE) and exhaust valve timing control position

sensor.

• Never place sensor where it is exposed to magnetism.

3.

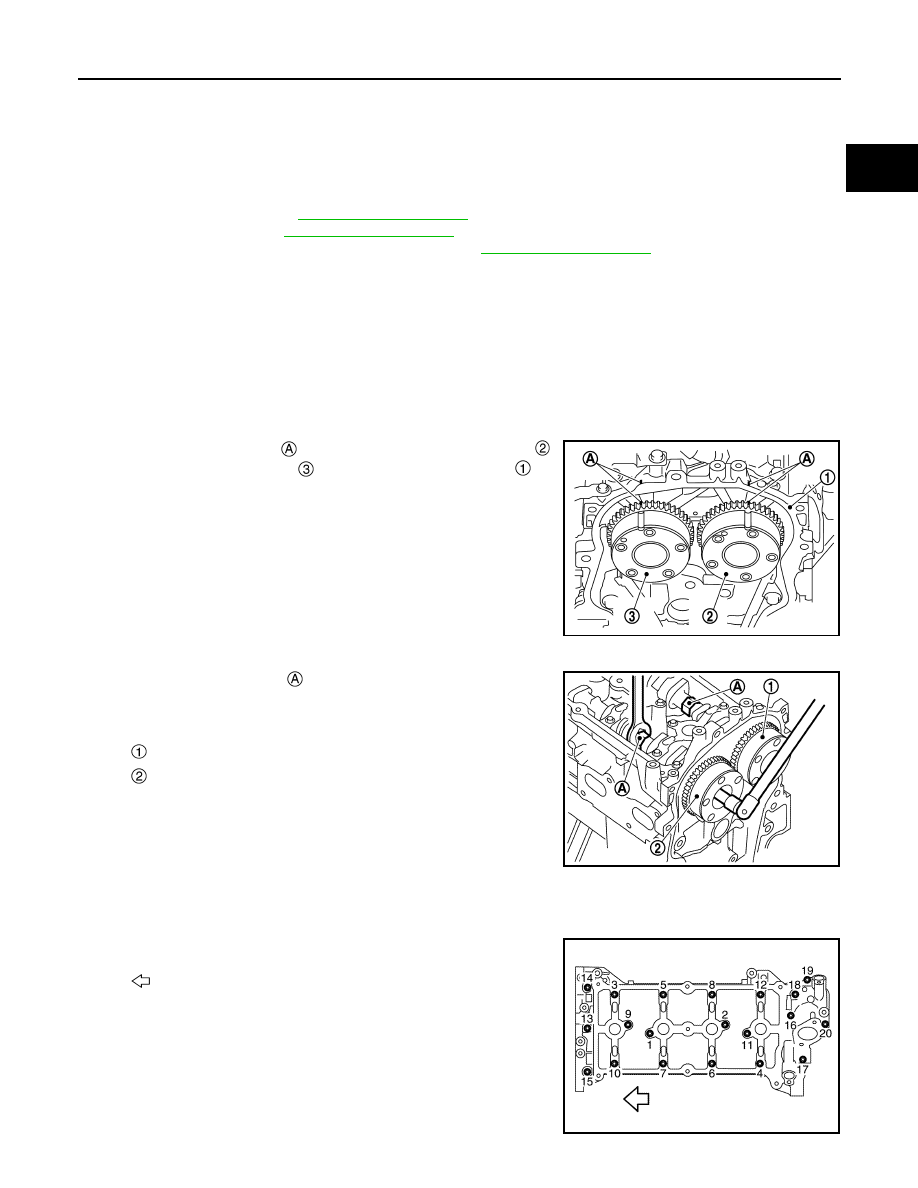

Put the matching mark

on the camshaft sprocket (INT)

,

camshaft sprocket (EXH)

and the camshaft bracket

as

shown in the figure.

NOTE:

It prevents the knock pin of the camshaft (INT) from engaging

with the incorrect pin hole when installing the camshaft sprocket

(INT).

4.

Remove camshaft sprockets (INT and EXH).

• Secure hexagonal part

of camshaft with a wrench. Loosen

camshaft sprocket mounting bolts and remove camshaft

sprocket.

CAUTION:

• Never rotate crankshaft or camshaft while timing chain

is removed. It causes interference between valve and

piston.

• Never loosen the mounting bolts with securing anything

other than the camshaft hexagonal part or with tensioning the timing chain.

5.

Remove camshaft bracket with the following procedure:

a.

Loosen mounting bolts in reverse order as shown in the figure.

JPBIA4404ZZ

: Camshaft sprocket (INT)

: Camshaft sprocket (EXH)

JPBIA4405ZZ

: Engine front

JPBIA4406ZZ