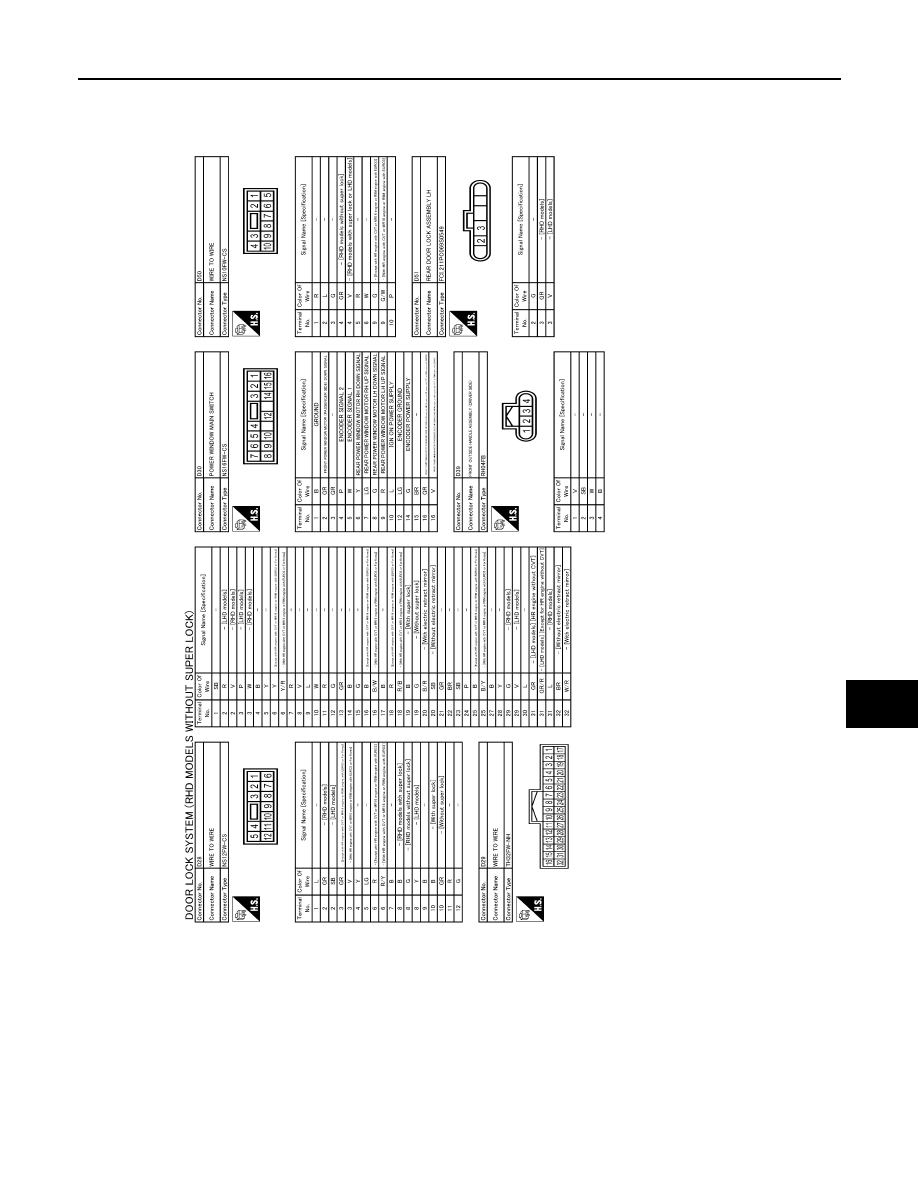

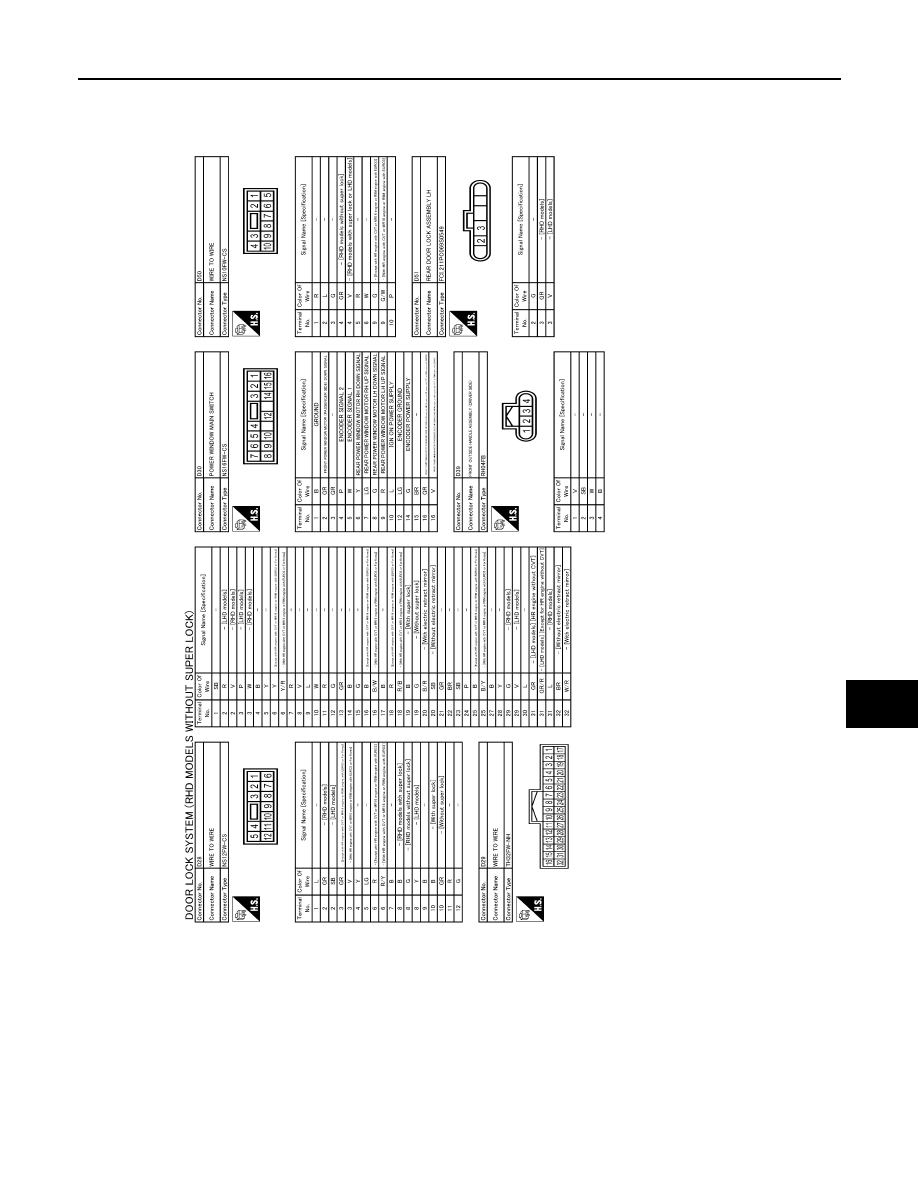

Qashqai J11. Door & Lock - part 34

DOOR & LOCK SYSTEM

DLK-545

< WIRING DIAGRAM >

[TYPE 4]

C

D

E

F

G

H

I

J

L

M

A

B

DLK

N

O

P

JRKWE3990GB

|

|

|

DOOR & LOCK SYSTEM DLK-545 < WIRING DIAGRAM > [TYPE 4] C D E F G H I J L M A B DLK N O P JRKWE3990GB |