Qashqai J11. Door & Lock - part 12

FUEL FILLER LID OPENER

DLK-193

< REMOVAL AND INSTALLATION >

[TYPE 1]

C

D

E

F

G

H

I

J

L

M

A

B

DLK

N

O

P

2.

Remove fuel mounting pin (1).

3.

Remove fixing screws, and then remove fuel filler lid assembly.

INSTALLATION

Note the following items, and install in the reverse order of removal.

CAUTION:

• After installation, check fuel filler lid assembly open/close, lock/unlock operation.

• After installation, apply the touch-up paint (the body color) onto the head of the fixing screws.

• Apply anti-corrosion wax to mounting surface of fixing screw and fuel filler lid to prevent rust.

NOTE:

The following table shows the specified values for checking normal installation status.

Unit: mm [in]

FUEL FILLER LID LOCK

FUEL FILLER LID LOCK : Removal and Installation

INFOID:0000000010434742

REMOVAL

1.

Fully open fuel filler lid.

2.

Remove luggage lower finisher RH. Refer to

.

3.

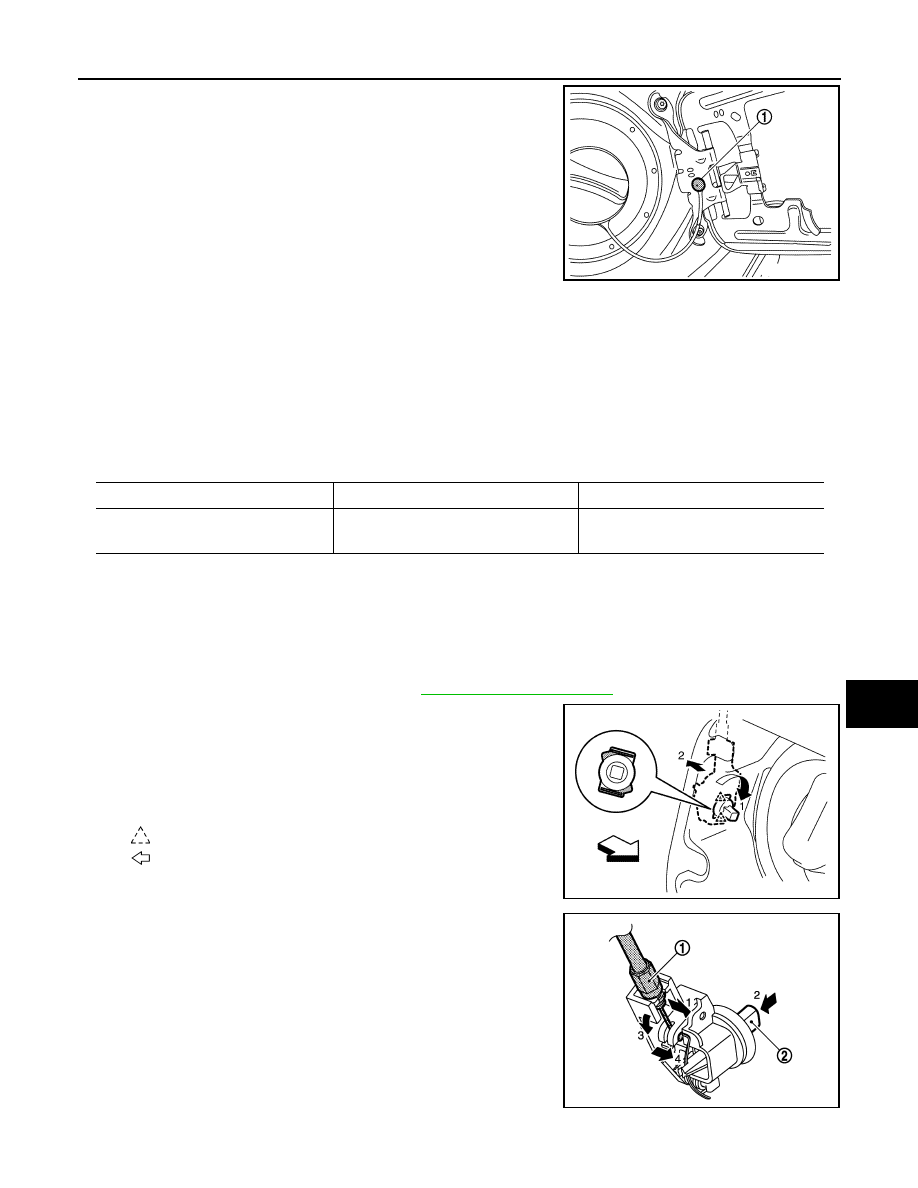

In the order of 1

→

2 as shown in the figure, rotate and disengage

fuel filler lid lock assembly, and then remove fuel filler lid lock

assembly.

NOTE:

Operation is performed easily when rotating fuel filler lid lock

from passenger room side.

4.

In the order of 1

→

4 as shown in the figure. Disengage fuel filler

lid opener cable (1). Remove fuel filler lid opener cable while

pressing stopper pin (2).

JMKIB3183ZZ

Clearance

Evenness

Fuel filler lid – Body side outer

3.7 – 5.3

(0.146 – 0.209)

(-1.0) – (+1.0)

[(-0.039) – (+0.039)]

: Pawl

: Vehicle front

JMKIB1094ZZ

JMKIA5719ZZ