Qashqai J11. Road wheels & tires - part 2

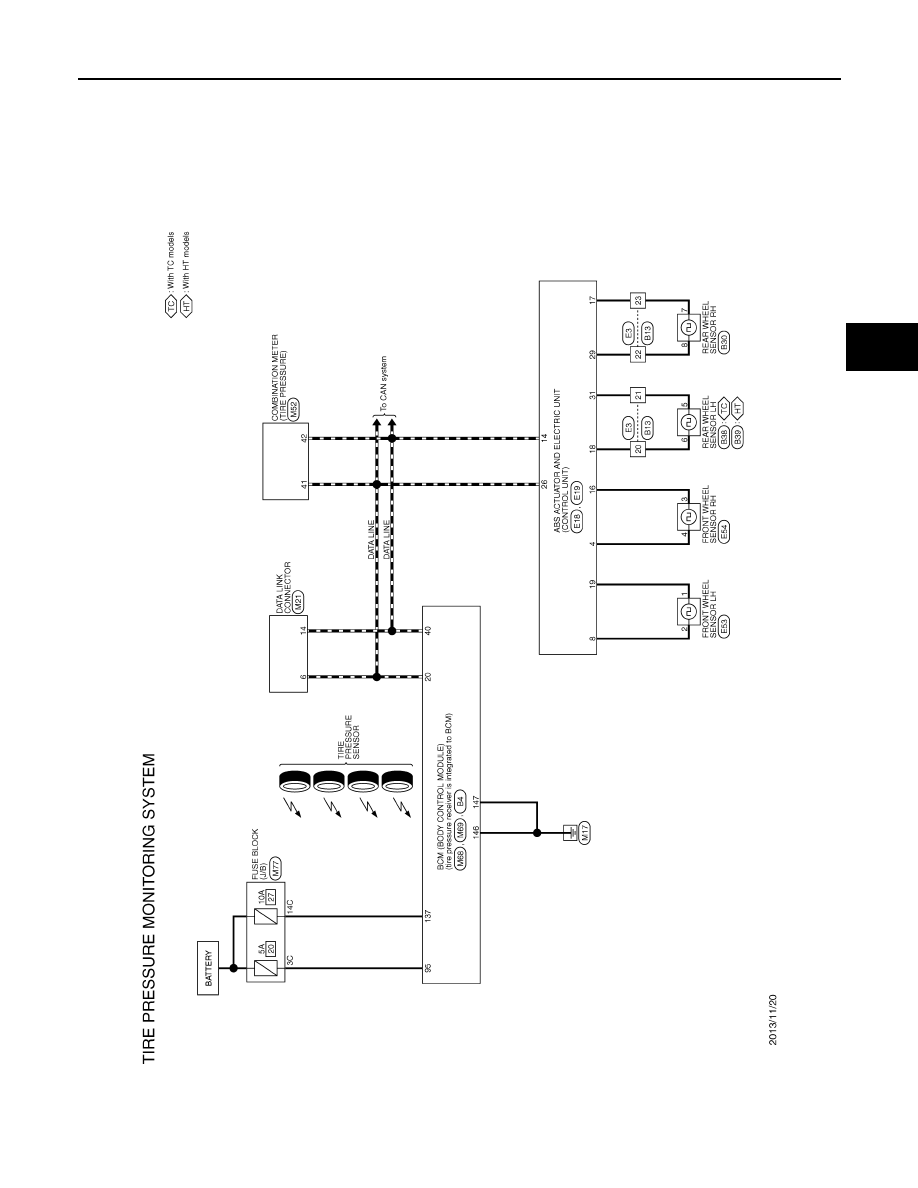

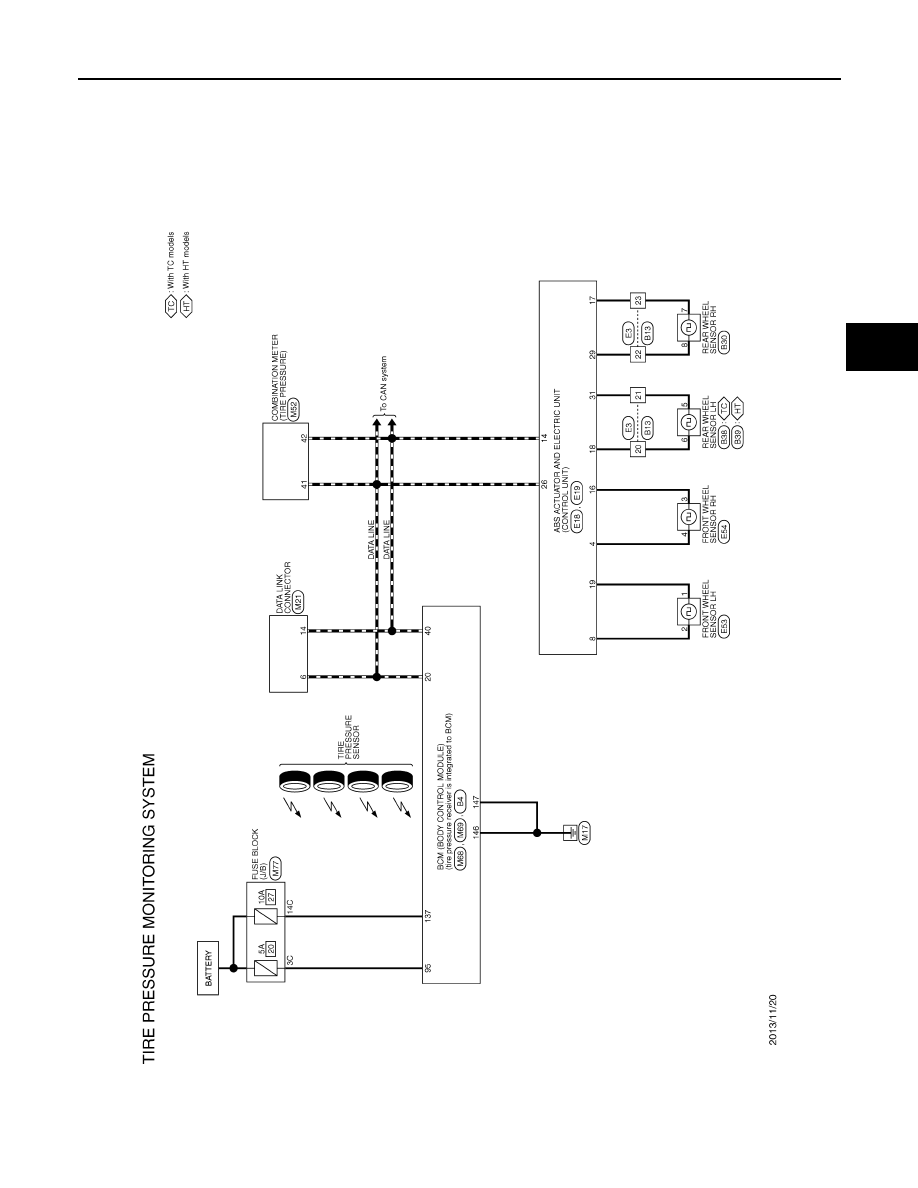

TIRE PRESSURE MONITORING SYSTEM

WT-21

< WIRING DIAGRAM >

[WITH TPMS]

C

D

F

G

H

I

J

K

L

M

A

B

WT

N

O

P

WIRING DIAGRAM

TIRE PRESSURE MONITORING SYSTEM

Wiring Diagram

INFOID:0000000010339518

JREWC0693GB

|

|

|

TIRE PRESSURE MONITORING SYSTEM WT-21 < WIRING DIAGRAM > [WITH TPMS] C D F G H I J K L M A B WT N O P WIRING DIAGRAM TIRE PRESSURE MONITORING SYSTEM Wiring Diagram INFOID:0000000010339518 JREWC0693GB |