Qashqai J11. Driveline - part 8

C1204 AWD SOLENOID

DLN-113

< DTC/CIRCUIT DIAGNOSIS >

[TRANSFER: TY30A]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

C1204 AWD SOLENOID

Description

INFOID:0000000010288274

Controls electric controlled coupling by command current from AWD control unit.

DTC Logic

INFOID:0000000010288275

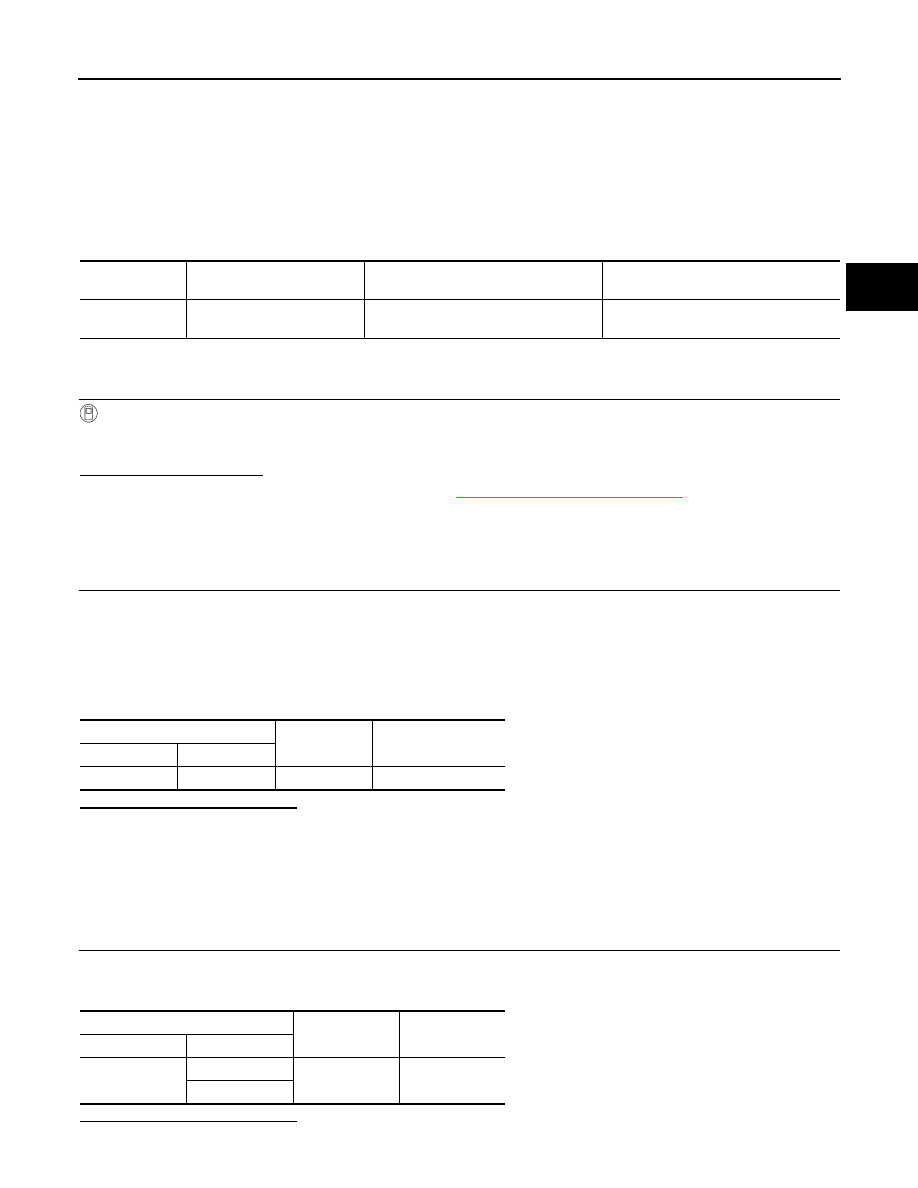

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

DTC REPRODUCTION PROCEDURE

With CONSULT

1.

Turn the ignition switch OFF to ON.

2.

Perform AWD control unit self-diagnosis.

Is DTC “C1204” detected?

YES

>> Proceed to diagnosis procedure. Refer to

DLN-113, "Diagnosis Procedure"

.

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000010288276

1.

CHECK AWD SOLENOID POWER SUPPLY

1.

Turn the ignition switch OFF.

2.

Disconnect AWD control unit harness connector.

3.

Turn the ignition switch ON.

CAUTION:

Never start the engine.

4.

Check the voltage between AWD control unit harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>>

Check the following. If any items are damaged, repair or replace damaged parts.

• 10A fuse (#28) open

- Short among 10A fuse (#28) connector, AWD control unit harness connector No. 9 terminal and

the ground

- Open between the battery and AWD control unit harness connector No. 9 terminal

2.

CHECK AWD SOLENOID GROUND

1.

Turn the ignition switch OFF.

2.

Check the continuity between AWD control unit harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 3.

DTC

Items

(CONSULT screen terms)

Diagnostic item is detected when...

Possible cause

C1204

AWDAWD SOLENOID

Malfunction related to AWD solenoid has

been detected.

Internal malfunction of electronic con-

trolled coupling

AWD control unit

Ground

Voltage (Approx.)

Connector

Terminal

B1

9

Ground

Battery voltage

AWD control unit

Ground

Continuity

Connector

Terminal

B1

10

Ground

Existed

11