Qashqai J11. Security control system - part 12

SENSOR CANCEL SWITCH

SEC-177

< DTC/CIRCUIT DIAGNOSIS >

[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

M

A

B

SEC

N

O

P

NO

>> Replace sensor cancel switch.

5.

CHECK INTERMITTENT INCIDENT

GI-44, "Intermittent Incident"

.

>> INSPECTION END

Component Inspection

INFOID:0000000010462807

1.

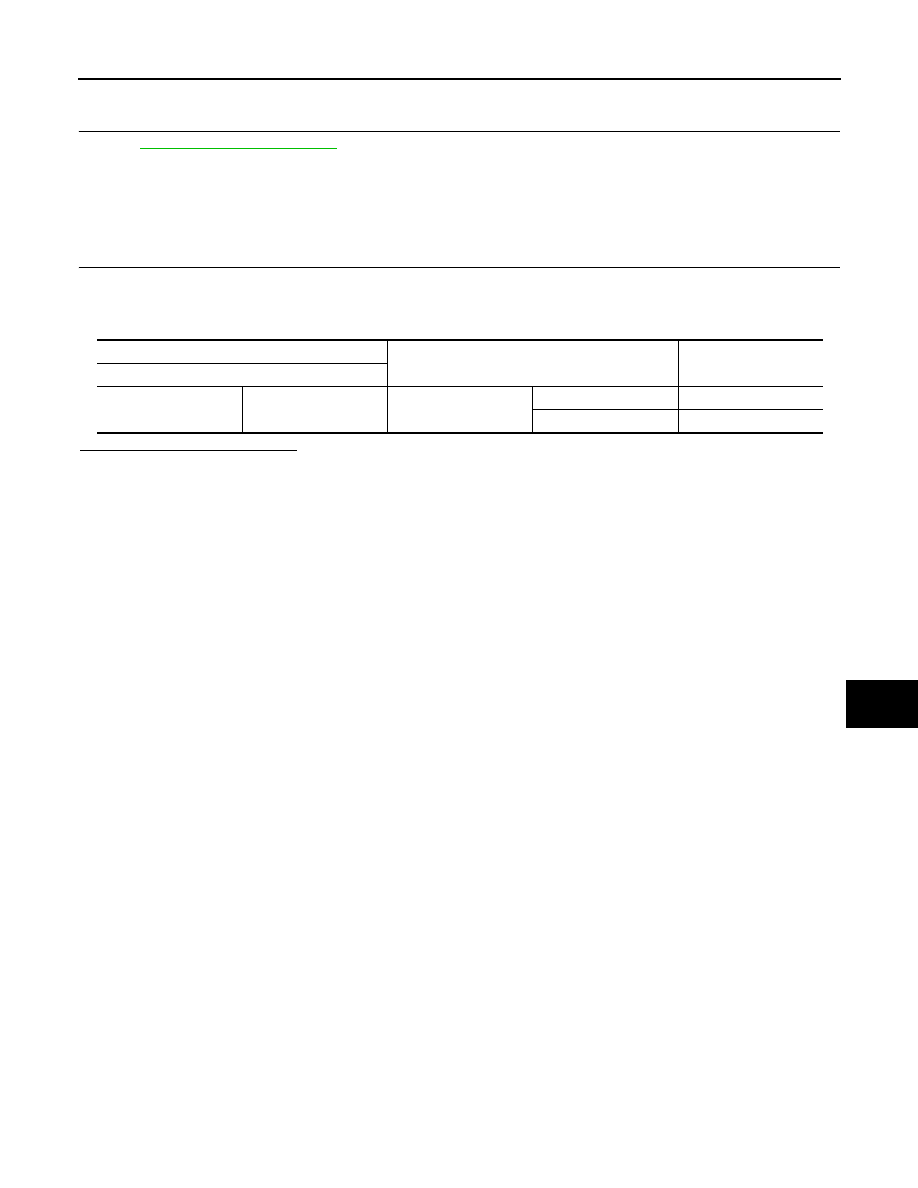

CHECK SENSOR CANCEL SWITCH

1.

Turn ignition switch OFF.

2.

Disconnect sensor cancel switch connector.

3.

Check continuity between sensor cancel switch terminals.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace sensor cancel switch.

Sensor cancel switch

Condition

Continuity

Terminal

5

6

Sensor cancel switch

Press

Existed

Release

Not existed