Qashqai J11. Heater & Air conditioning Control System - part 10

COMPONENT PARTS

HAC-145

< SYSTEM DESCRIPTION >

[MANUAL AIR CONDITIONING]

C

D

E

F

G

H

J

K

L

M

A

B

HAC

N

O

P

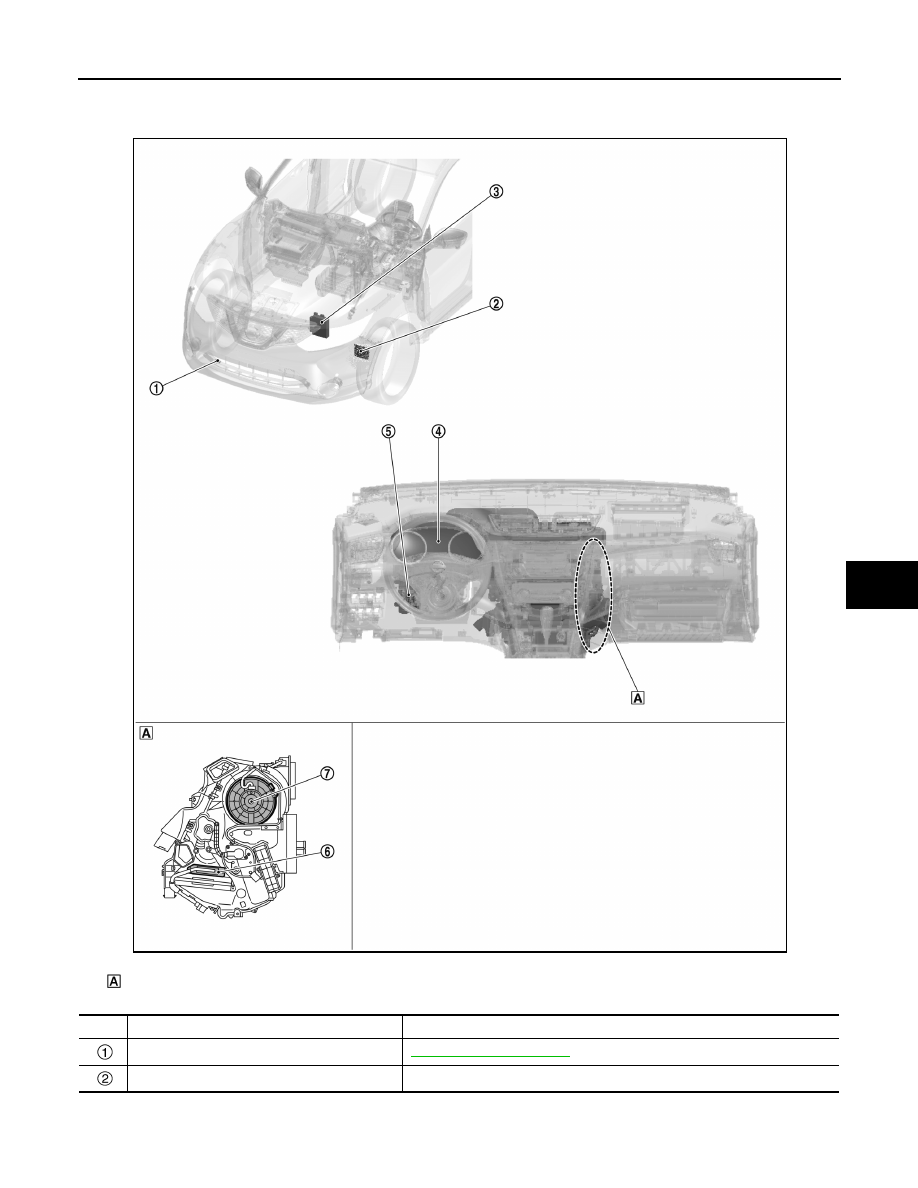

PTC HEATER CONTROL SYSTEM : Component Parts Location

INFOID:0000000010499399

Right side of A/C unit assembly

JMIIA3547ZZ

No.

Component

Function

Ambient sensor

PTC relay-1/2/3

PTC relay is controlled by BCM, and supplies power supply to PTC heater.