Qashqai J11. Heater & Air conditioning Control System - part 8

BLOWER MOTOR

HAC-113

< DTC/CIRCUIT DIAGNOSIS >

[AUTOMATIC AIR CONDITIONING]

C

D

E

F

G

H

J

K

L

M

A

B

HAC

N

O

P

YES

>> GO TO 2.

NO

>> Replace blower motor. Refer to

VTL-17, "Removal and Installation"

.

2.

CHECK BLOWER MOTOR-II

Check that there is not breakage or damage in the blower motor.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Replace blower motor. Refer to

VTL-17, "Removal and Installation"

.

3.

CHECK BLOWER MOTOR-III

Check that blower motor turns smoothly.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace blower motor. Refer to

VTL-17, "Removal and Installation"

.

Component Inspection (Blower Relay)

INFOID:0000000010432237

1.

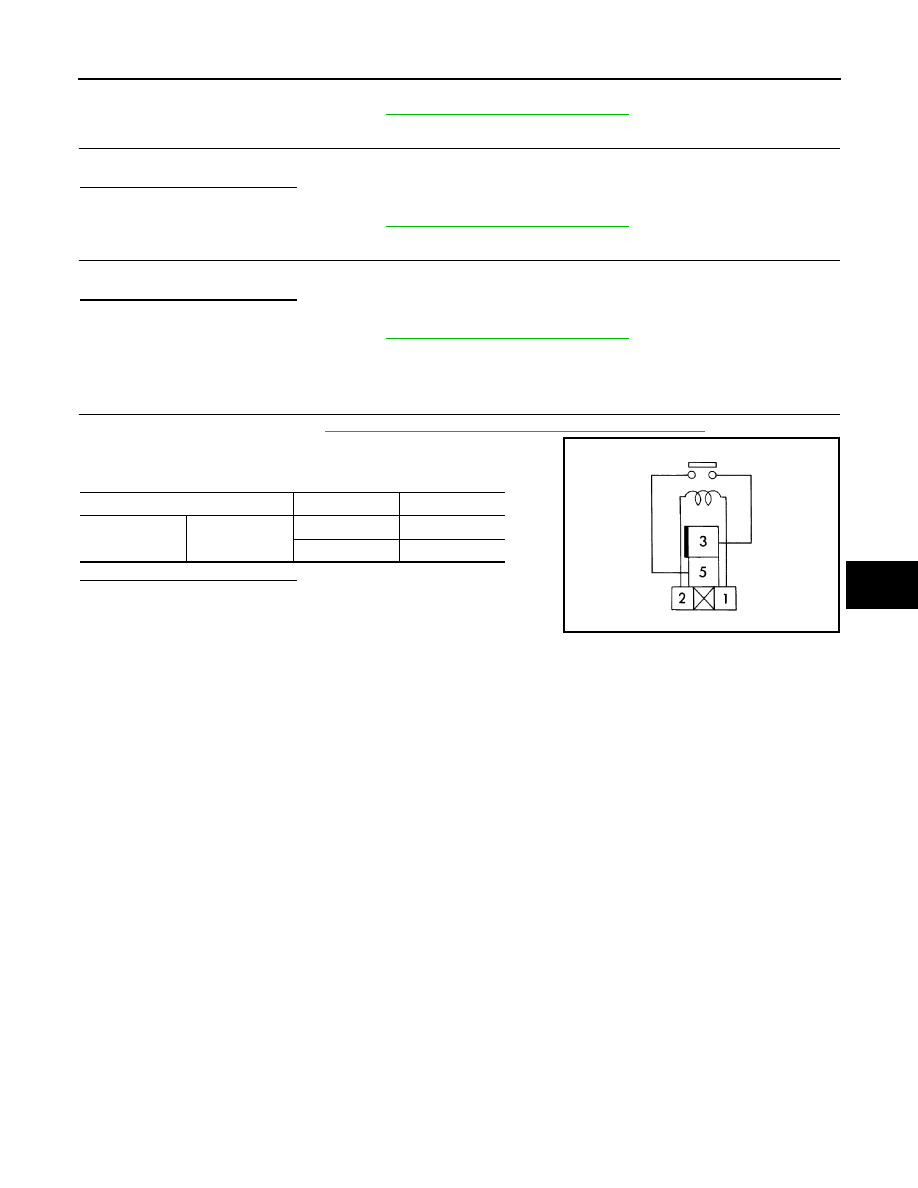

CHECK BLOWER RELAY

1.

Remove blower relay. Refer to

PG-104, "Fuse, Connector and Terminal Arrangement"

2.

Check continuity between blower relay terminal 3 and 5 when

the voltage is supplied between terminal 1 and 2.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace blower relay.

Terminal

Voltage

Continuity

3

5

ON

Existed

OFF

Not existed

JSIIA1551ZZ