Qashqai J11. Exterior Lighting system - part 18

EXL-274

< DTC/CIRCUIT DIAGNOSIS >

[HALOGEN HEADLAMP]

HEADLAMP (HI) CIRCUIT

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair or replace harness.

4.

CHECK HEADLAMP (HI) BULB

Check the applicable headlamp (HI) bulb.

Is the inspection result normal?

YES

>> Check the corresponding headlamp (HI) bulb socket. Repair or replace if necessary.

NO

>> Replace the corresponding headlamp (HI) bulb. Refer to

.

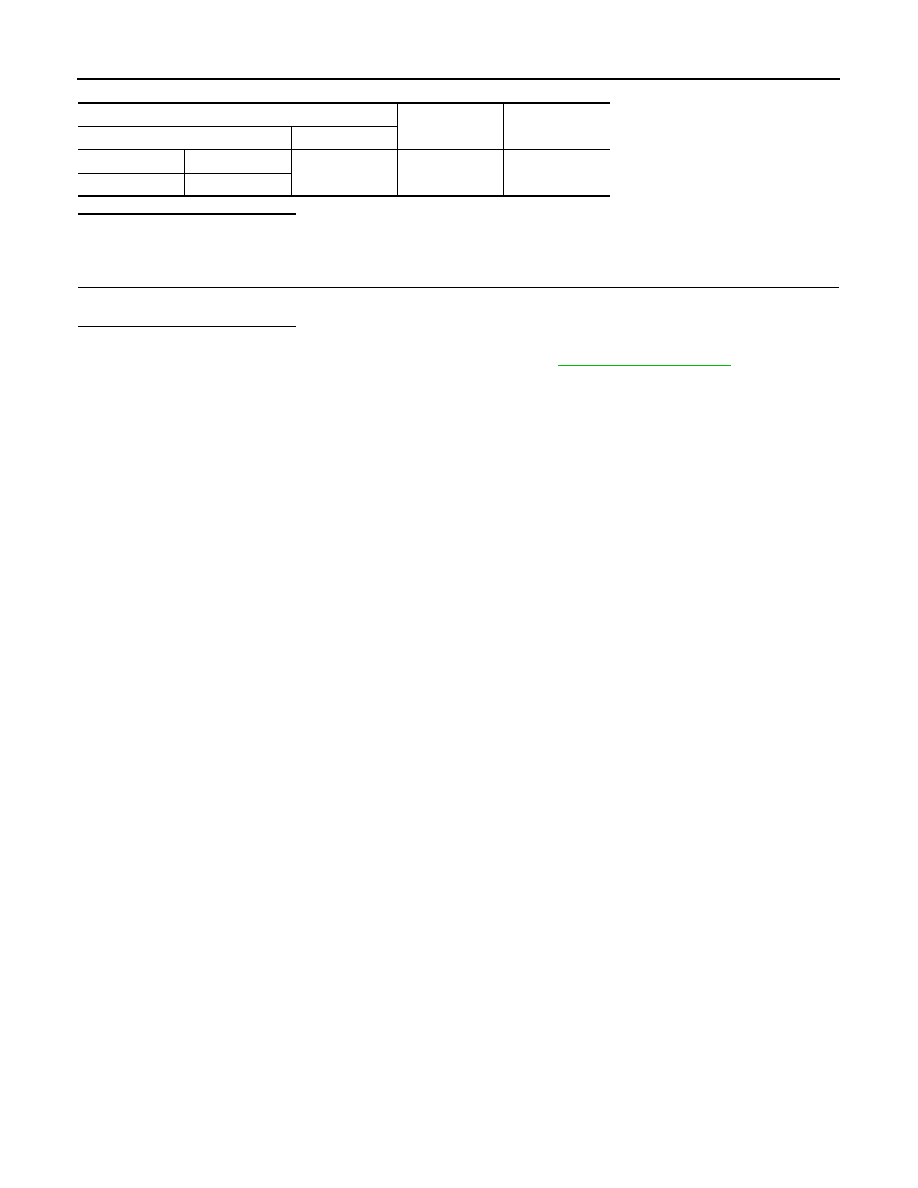

Front combination lamp

—

Continuity

Connector

Terminal

RH

E92

1

Ground

Existed

LH

E90