Qashqai J11. Exterior Lighting system - part 19

EXL-290

< DTC/CIRCUIT DIAGNOSIS >

[HALOGEN HEADLAMP]

REAR FOG LAMP CIRCUIT

REAR FOG LAMP CIRCUIT

Component Function Check

INFOID:0000000010469989

1.

CHECK REAR FOG LAMP OPERATION

With CONSULT

1.

Select “HEAD LAMP” of “BCM” using CONSULT.

2.

Select “RR FOG LAMP” in “Active Test” mode.

3.

With operating the test items, check that the rear fog lamp is turned ON.

Is the inspection result normal?

YES

>> Rear fog lamp circuit is normal.

NO

>> Refer to

EXL-290, "Diagnosis Procedure"

.

Diagnosis Procedure

INFOID:0000000010469990

1.

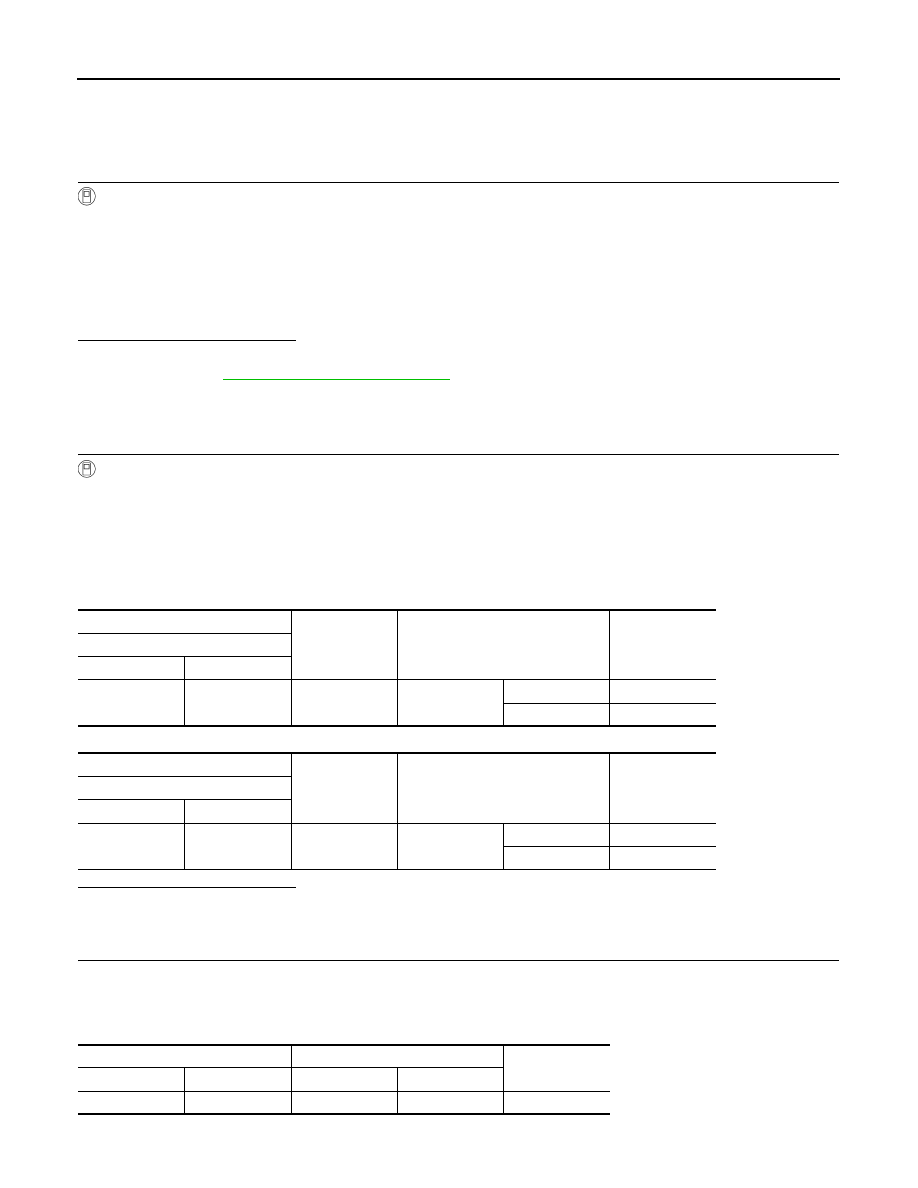

CHECK REAR FOG LAMP OUTPUT VOLTAGE

With CONSULT

1.

Turn ignition switch OFF.

2.

Disconnect rear fog lamp connector.

3.

Turn ignition switch ON.

4.

Select “HEAD LAMP” of “BCM” using CONSULT.

5.

Select “RR FOG LAMP” in “Active Test” mode.

6.

With operating the test items, check voltage between rear fog lamp harness connector and ground.

LHD models

RHD models

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> GO TO 2.

2.

CHECK REAR FOG LAMP POWER SUPPLY CIRCUIT (OPEN)

1.

Turn ignition switch OFF.

2.

Disconnect BCM connector.

3.

Check continuity between BCM harness connector and rear fog lamp harness connector.

LHD models

On

: Rear fog lamp ON

Off

: Rear fog lamp OFF

+

-

Test item

Voltage

Rear fog lamp

Connector

Terminal

B24

1

Ground

RR FOG LAMP

On

9 – 16 V

Off

0 V

+

-

Test item

Voltage

Rear fog lamp

Connector

Terminal

D83

1

Ground

RR FOG LAMP

On

9 – 16 V

Off

0 V

BCM

Rear fog lamp

Continuity

Connector

Terminal

Connector

Terminal

B3

122

B24

1

Existed