Qashqai J11. Engine lubrication system (HRA2DDT, K9K, MR20DD) - part 4

ENGINE OIL

LU-49

< PERIODIC MAINTENANCE >

[R9M]

C

D

E

F

G

H

I

J

K

L

M

A

LU

N

P

O

5.

Check oil pressure with engine running under no-load.

NOTE:

When engine oil temperature is low, engine oil pressure becomes high.

If difference is extreme, check oil passage and oil pump for oil leakage.

6.

After the inspections, install oil pressure switch with the following procedure:

a.

Tighten oil pressure switch to specification.

b.

Check engine oil level.

c.

After warming up engine, check that there is no leakage of engine oil with running engine.

Draining

INFOID:0000000010284225

WARNING:

• Be careful not to get burned, as engine oil may be hot.

• Prolonged and repeated contact with used engine oil may cause skin cancer. Try to avoid direct skin

contact with used engine oil. If skin contact is made, wash thoroughly with soap or hand cleaner as

soon as possible.

1.

Warm up the engine, and check for engine oil leakage from engine components. Refer to

2.

Stop the engine and wait for 10 minutes.

3.

Remove engine undercover.

4.

Loosen oil level gauge.

5.

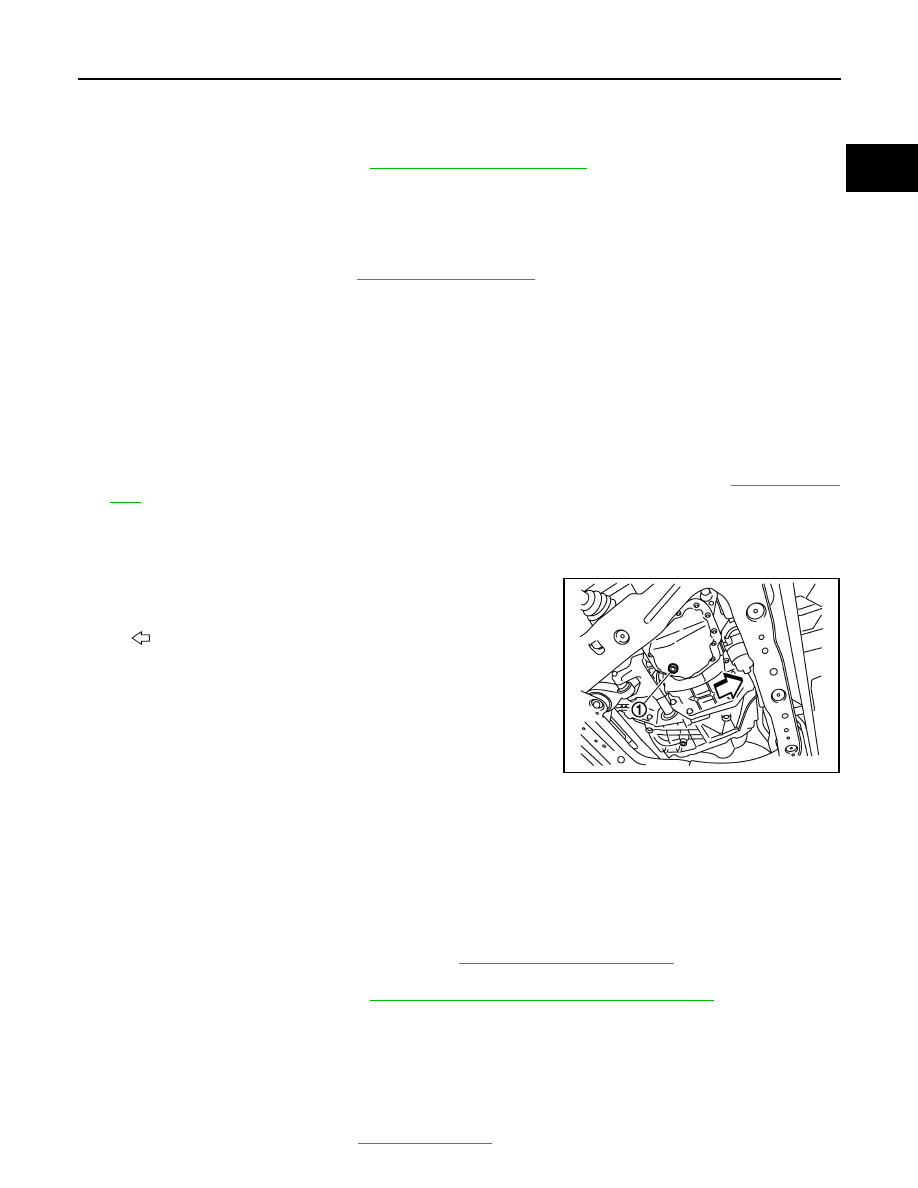

Remove oil pan drain plug (1) using a square driver [8 mm

(0.315 in)]. Drain engine oil.

Refilling

INFOID:0000000010284226

1.

Install drain plug with new washer.

CAUTION:

Be sure to clean drain plug and install with new washer.

2.

Refill with new engine oil.

Engine oil specification and viscosity: Refer to

MA-59, "Fluids and Lubricants"

.

CAUTION:

• The refill capacity depends on the engine oil temperature and drain time. Use these specifica-

tions for reference only.

• Always use oil level gauge to determine the proper amount of engine oil in the engine.

3.

Warm up engine and check area around drain plug and oil filter body for engine oil leakage.

4.

Stop engine and wait for 10 minutes.

5.

Check the engine oil level. Refer to

Engine oil pressure

: Refer to

Tightening torque

: Refer to

: Vehicle front

E1BIA0601ZZ

Tightening torque

: 50 N·m (5.1 Kg-m, 37 ft-lb)

Engine oil capacity

: Refer to