Qashqai J11. Engine mechanical (HRA2DDT, K9K, MR20DD) - part 23

SERVICE DATA AND SPECIFICATIONS (SDS)

EM-353

< SERVICE DATA AND SPECIFICATIONS (SDS)

[K9K]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

VALVE LIFTER

Unit: mm (in)

VALVE CLEARANCE

Unit: mm (in)

AVAILABLE VALVE LIFTER

Unit: mm (in)

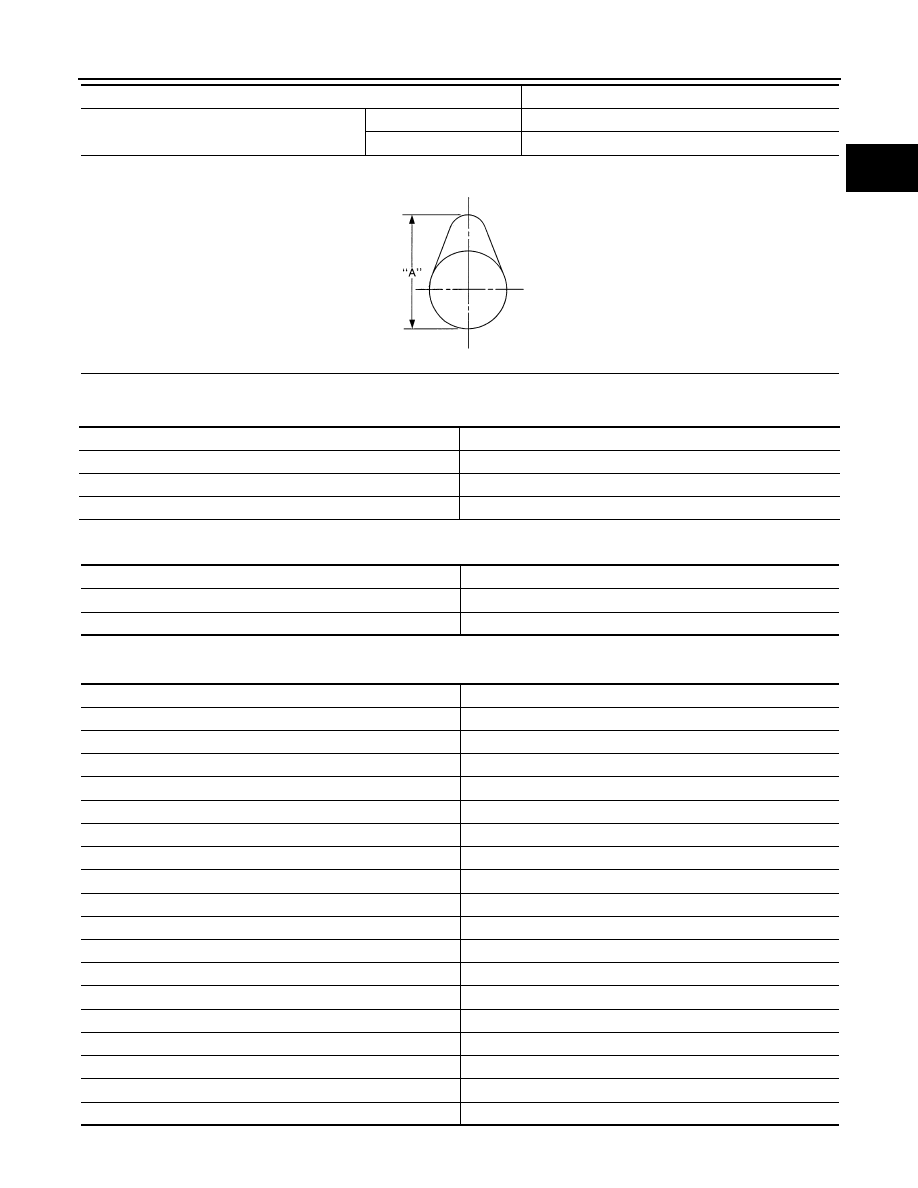

Camshaft cam height “A”

Intake

44.012 - 44.018 (1.7327 - 1.7329)

Exhaust

44.592 - 44.598 (1.7555 - 1.7557)

Items

Standard

SEM671

Items

Standard

Valve lifter outer diameter

34.965 - 34.985 (1.3767 - 1.3774)

Valve lifter hole diameter

35.000 - 35.040 (1.3780 - 1.3795)

Valve lifter clearance

0.015 - 0.075 (0.0006 - 0.0030)

Items

Cold

Intake

0.125 - 0.250 (0.0049 - 0.0098)

Exhaust

0.325 - 0.450 (0.0128 - 0.0177)

Part number

Thickness

13229BN700

7.550 (0.2972)

13229BN701

7.575 (0.2982)

13229BN702

7.600 (0.2992)

13229BN703

7.625 (0.3002)

13229BN704

7.650 (0.3012)

13229BN705

7.675 (0.3022)

13229BN706

7.700 (0.3031)

13229BN707

7.725 (0.3041)

13229BN708

7.750 (0.3051)

13229BN709

7.775 (0.3061)

13229BN710

7.800 (0.3071)

13229BN711

7.825 (0.3081)

13229BN712

7.850 (0.3091)

13229BN713

7.875 (0.3100)

13229BN714

7.900 (0.3110)

13229BN715

7.925 (0.3120)

13229BN716

7.950 (0.3130)

13229BN717

7.975 (0.3140)