Qashqai J11. Engine mechanical (HRA2DDT, K9K, MR20DD) - part 21

ENGINE ASSEMBLY

EM-321

< UNIT REMOVAL AND INSTALLATION >

[K9K]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

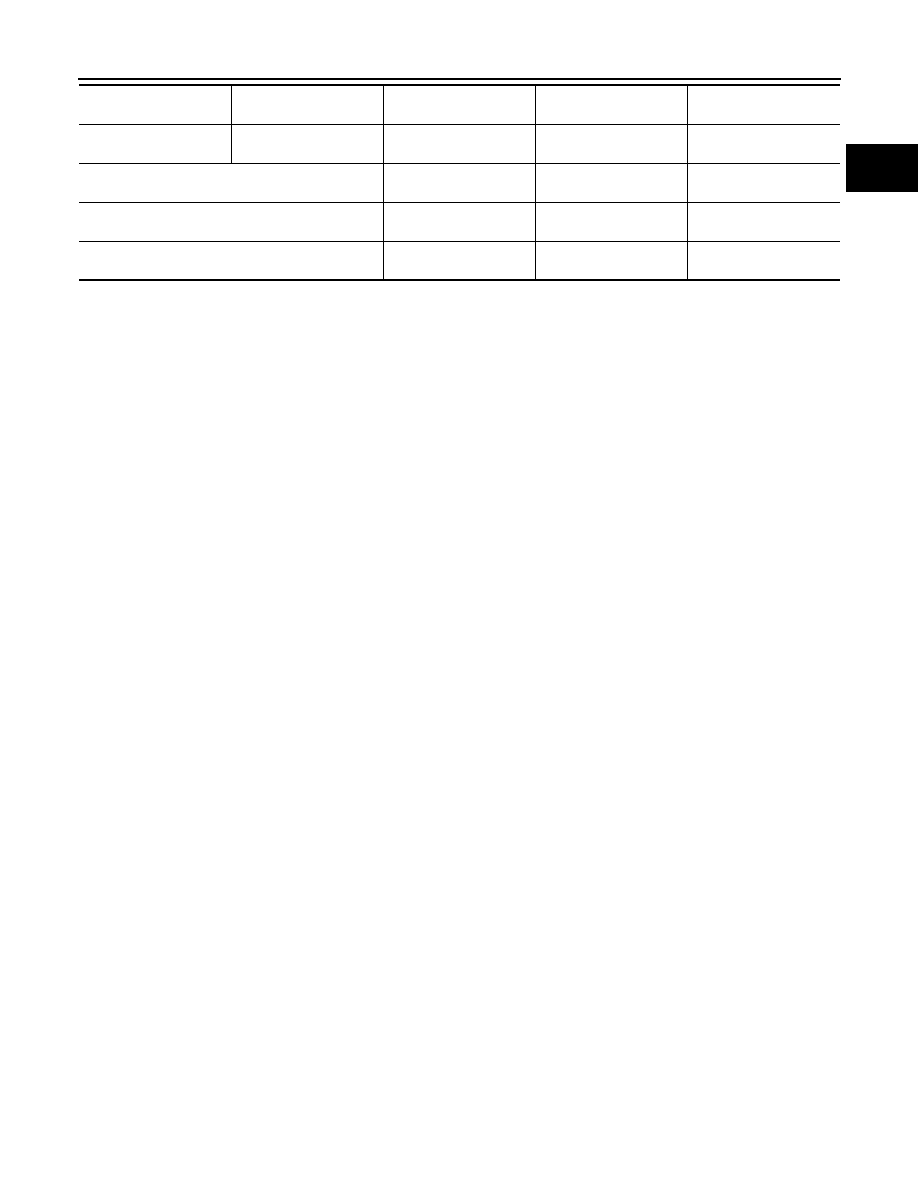

*: Power steering fluid, brake fluid, etc.

Transmission / transaxle

fluid

AT & CVT Models

Leakage

Level / Leakage

Leakage

Transmission / transaxle

fluid

MT Models

Level / Leakage

Leakage

Level / Leakage

Other oils and fluid*

Level

Leakage

Level

Fuel

Leakage

Leakage

Leakage

Exhaust gases

—

Leakage

—