Qashqai J11. Engine mechanical (HRA2DDT, K9K, MR20DD) - part 19

EXHAUST MANIFOLD

EM-289

< REMOVAL AND INSTALLATION >

[K9K]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

EXHAUST MANIFOLD

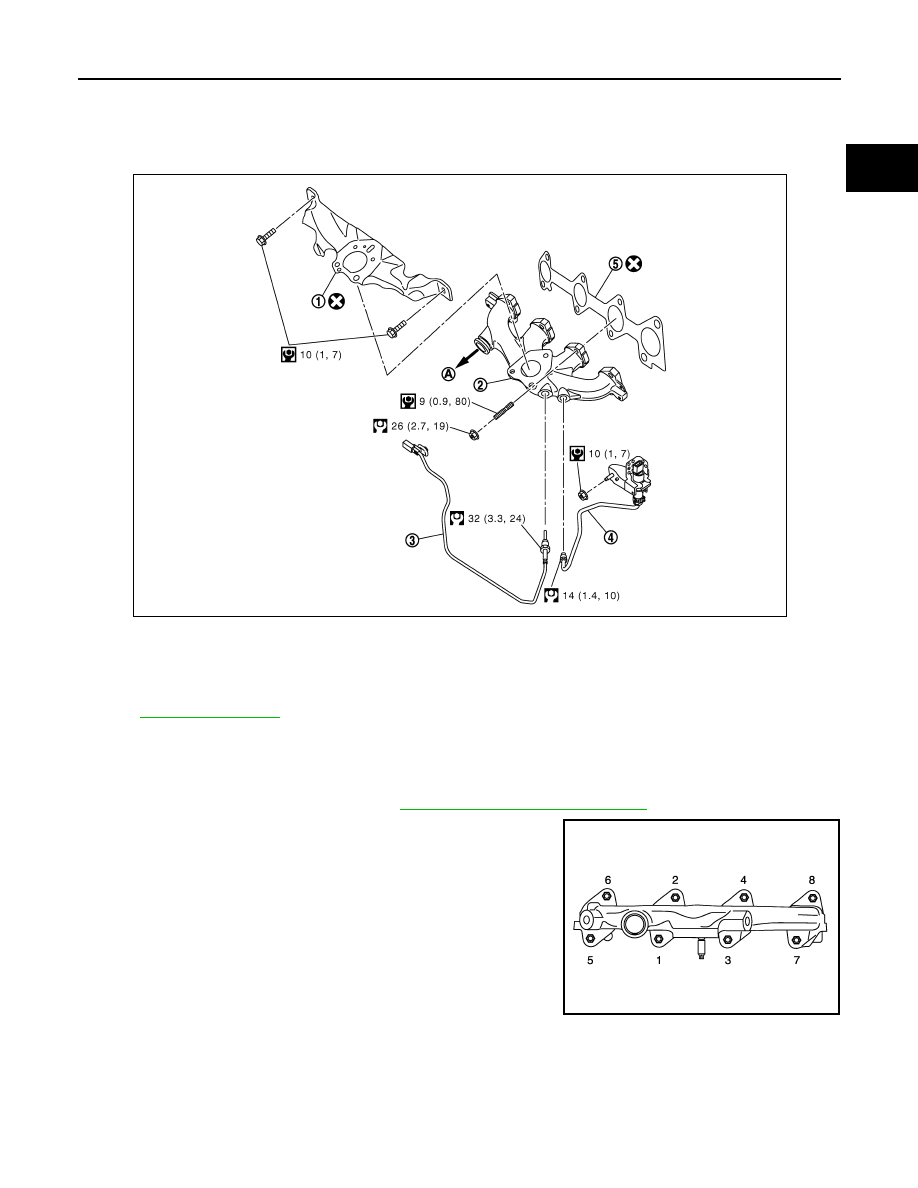

Exploded View

INFOID:0000000010287205

for symbol marks in the figure.

Removal and Installation

INFOID:0000000010282072

REMOVAL

1.

Remove turbocharger assembly. Refer to

EM-287, "Removal and Installation"

2.

Loosen exhaust manifold mounting nuts in the reverse order as

shown. Then remove exhaust manifold.

CAUTION:

Be careful not to deform each turbocharger piping when pulling

out the assembly.

INSTALLATION

1.

Clean the surface of exhaust manifold and cylinder head.

2.

Install new gasket to cylinder head.

1.

Gasket

2.

Exhaust manifold

3.

Exhaust gas temperature sensor 1

4.

Exhaust gas pressure sensor 1

5.

Gasket

A.

To high pressure EGR pipe

E1BIA0886GB

JPBIA3039ZZ