Qashqai J11. Engine mechanical (HRA2DDT, K9K, MR20DD) - part 17

SERVICE DATA AND SPECIFICATIONS (SDS)

EM-257

< SERVICE DATA AND SPECIFICATIONS (SDS)

[MR20DD]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

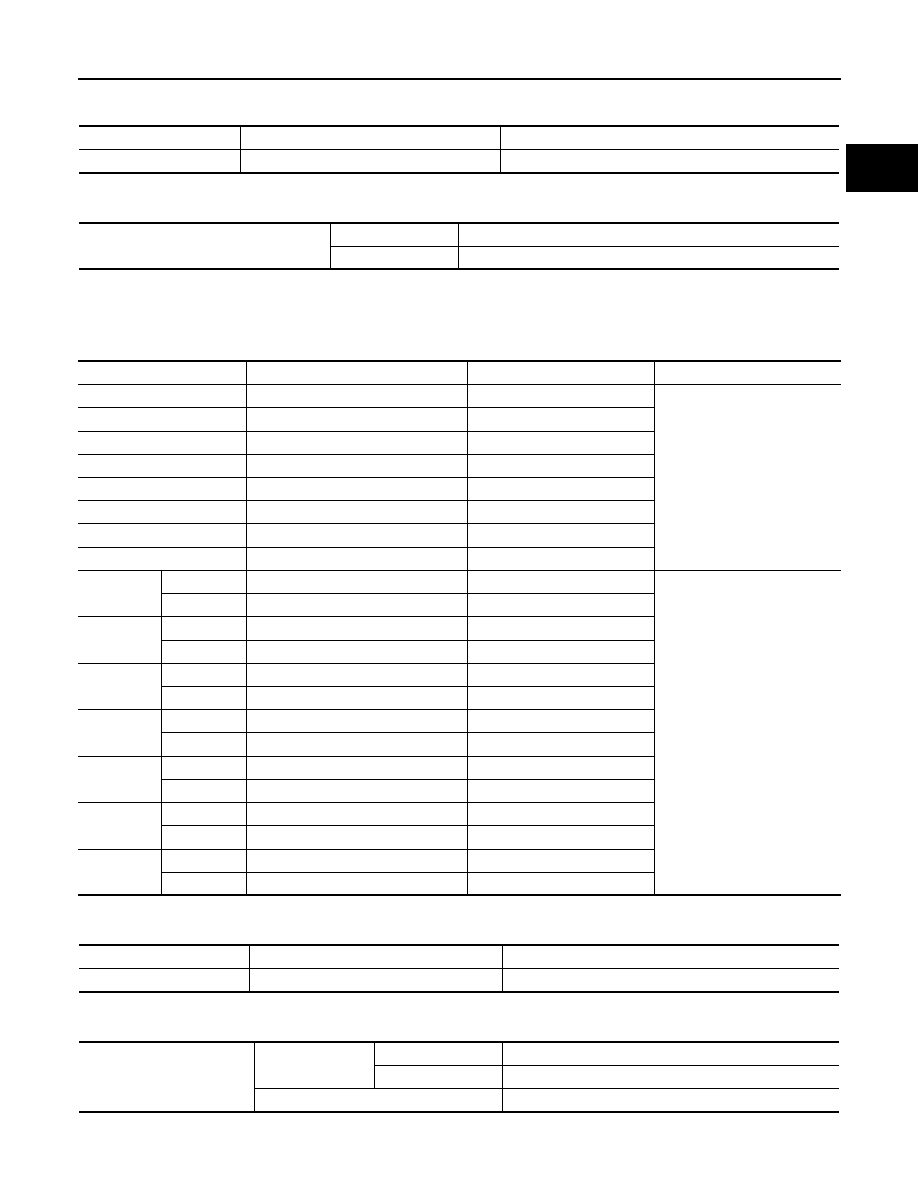

UNDERSIZE TABLE

Unit: mm (in)

CONNECTING ROD BEARING OIL CLEARANCE

Unit: mm (in)

Main Bearing

INFOID:0000000010735685

MAIN BEARING GRADE TABLE (ALL JOURNALS)

Unit: mm (in)

UNDERSIZE TABLE

Unit: mm (in)

MAIN BEARING OIL CLEARANCE

Unit: mm (in)

Items

Thickness

Crank pin journal diameter

US 0.25 (0.0098)

1.623 - 1.631 (0.0639 - 0.0642)

Grind so that bearing clearance is the specified value.

Connecting rod bearing oil clearance

Standard

0.037 - 0.047 (0.0015 - 0.0019)

Limit

0.07 (0.0028)

Grade number

Thickness

Identification color

Remarks

0

1.996 - 1.999 (0.0786 - 0.0787)

Black - Black

Grade and color are the same

for upper and lower bearings.

1

1.999 - 2.002 (0.0787 - 0.0788)

Brown - Brown

2

2.002 - 2.005 (0.0788 - 0.0789)

Green - Green

3

2.005 - 2.008 (0.0789 - 0.0791)

Yellow - Yellow

4

2.008 - 2.011 (0.0791 - 0.0792)

Blue - Blue

5

2.011 - 2.014 (0.0792 - 0.0793)

Pink - Pink

6

2.014 - 2.017 (0.0793 - 0.0794)

Purple - Purple

7

2.017 - 2.020 (0.0794 - 0.0795)

White - White

01

UPR

1.996 - 1.999 (0.0786 - 0.0787)

Black - Black

Grade and color are different

between upper and lower bear-

ings.

LWR

1.999 - 2.002 (0.0787 - 0.0788)

Brown - Brown

12

UPR

1.999 - 2.002 (0.0787 - 0.0788)

Brown - Brown

LWR

2.002 - 2.005 (0.0788 - 0.0789)

Green - Green

23

UPR

2.002 - 2.005 (0.0788 - 0.0789)

Green - Green

LWR

2.005 - 2.008 (0.0789 - 0.0791)

Yellow - Yellow

34

UPR

2.005 - 2.008 (0.0789 - 0.0791)

Yellow - Yellow

LWR

2.008 - 2.011 (0.0791 - 0.0792)

Blue - Blue

45

UPR

2.008 - 2.011 (0.0791 - 0.0792)

Blue - Blue

LWR

2.011 - 2.014 (0.0792 - 0.0793)

Pink - Pink

56

UPR

2.011 - 2.014 (0.0792 - 0.0793)

Pink - Pink

LWR

2.014 - 2.017 (0.0793 - 0.0794)

Purple - Purple

67

UPR

2.014 - 2.017 (0.0793 - 0.0794)

Purple - Purple

LWR

2.017 - 2.020 (0.0794 - 0.0795)

White - White

Items

Thickness

Main journal diameter

US 0.25 (0.0098)

2.126 - 2.134 (0.0837 - 0.0840)

Grind so that bearing clearance is the specified value.

Main bearing oil clearance

Standard

No. 1 and 4

0.024 - 0.034 (0.0009 - 0.0013)

No. 2, 3 and 5

0.012 - 0.022 (0.0005 - 0.0009)

Limit

0.065 (0.0026)