Qashqai J11. Engine mechanical (HRA2DDT, K9K, MR20DD) - part 24

PREPARATION

EM-369

< PREPARATION >

[R9M]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

PREPARATION

PREPARATION

Special Service Tools

INFOID:0000000010281961

NISSAN tool number

(RENAULT tool No.)

Tool name

Description

—

(Mot. 1979)

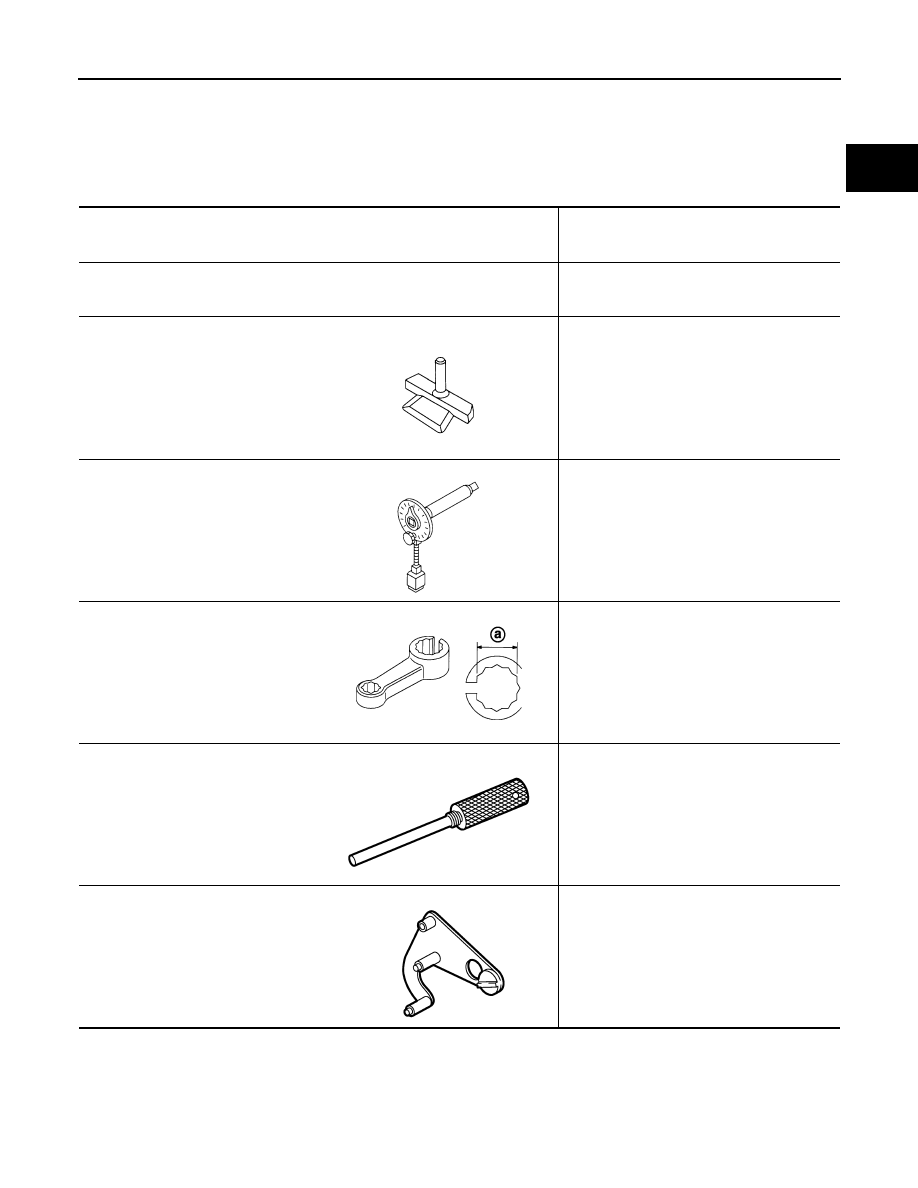

Piston ring compressor

Installing piston assembly into cylinder bore

KV10111100

(

—

)

Seal cutter

Removing oil pan and front cover. etc

KV10112100

(

—

)

Angle wrench

Tightening bolts for bearing cap, cylinder

head, etc. in angle

KV10114400

(

—

)

Heated oxygen sensor wrench

Loosening or tightening air fuel ratio sensor

a: 22 mm (0.87 in)

—

(Mot. 1970)

TDC set pin

To lock engine at TDC

—

(Mot. 1969)

Camshaft timing tool

To lock camshaft when changing timing chain

NT046

NT014

JPBIA0397ZZ

JPBIA0629ZZ

JPBIA0628ZZ