Qashqai J11. Engine control system (MR20DD) - part 12

ECM-178

< DTC/CIRCUIT DIAGNOSIS >

[MR20DD]

P0087, P0088, P0090 FRP CONTROL SYSTEM

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Replace high pressure fuel pump. Refer to

EM-159, "Removal and Installation"

2.

CHECK HIGH PRESSURE FUEL PUMP-2

WITH CONSULT

1.

Reconnect high pressure fuel pump harness connector.

2.

Start the engine.

3.

Check “FUEL PRES SEN” in “DATA MONITOR” of “ENGINE” with CONSULT.

WITHOUT CONSULT

1.

Start the engine.

2.

Check fuel rail pressure sensor signal voltage.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace high pressure fuel pump. Refer to

EM-159, "Removal and Installation"

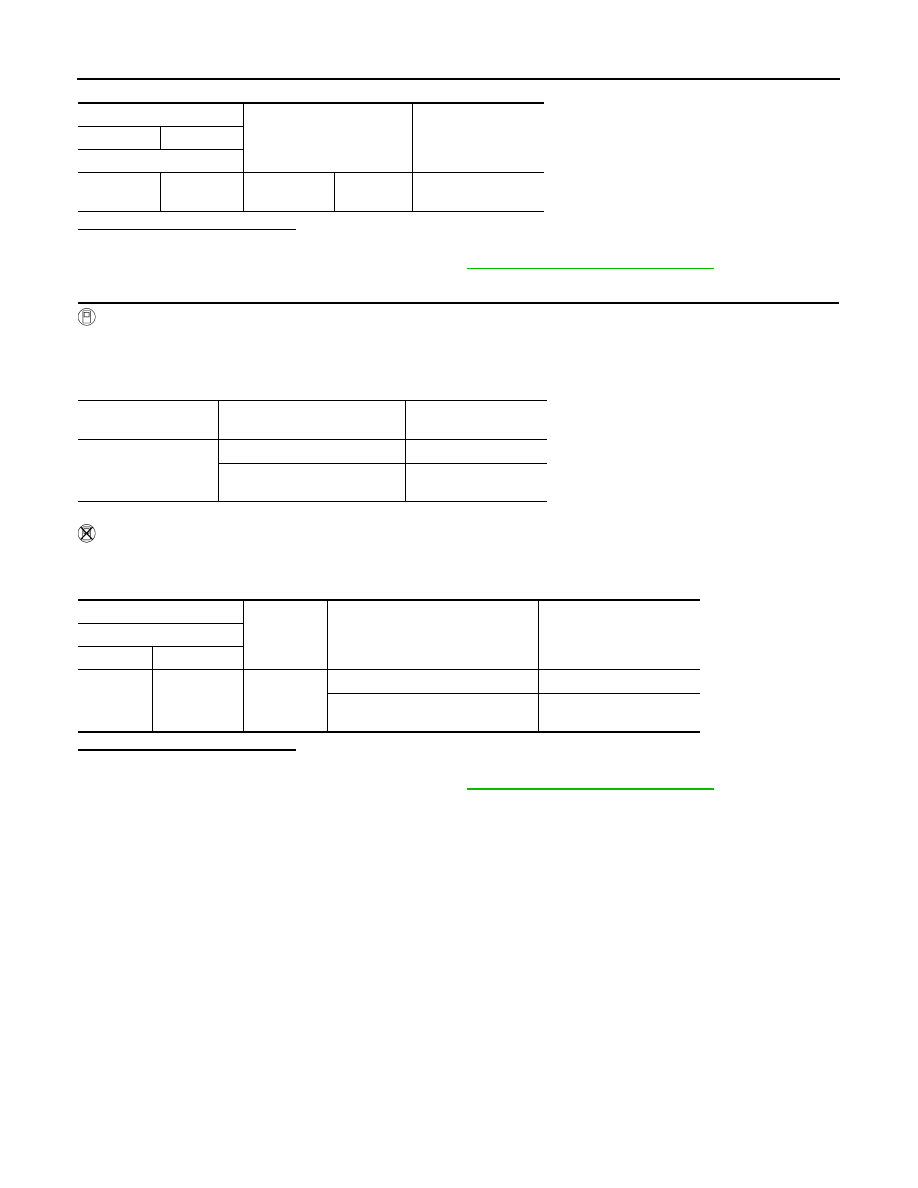

High pressure fuel pump

Condition

Resistance

+

−

Terminal

1

2

Temperature

°

C (

°

F)

20 – 30 (68

– 86)

0.46 - 0.51

Ω

Data monitor item

Condition

Voltage

(Approx.)

FUEL PRES SEN V

Engine speed: idle

820 – 1,140 mV

Engine speed: Revving engine

from idle to 4,000 rpm

820 – 2,900 mV

+

Ground

Condition

Voltage

(Approx.)

Fuel rail pressure sensor

Connector

Terminal

F95

2

Ground

Engine speed: idle

0.82 – 1.14 V

Engine speed: Revving engine

from idle to 4,000 rpm

0.82 – 2.9 V