Qashqai J11. Engine control system (K9K) - part 24

P2264 WATER IN FUEL SENSOR

ECK-369

< DTC/CIRCUIT DIAGNOSIS >

[K9K]

C

D

E

F

G

H

I

J

K

L

M

A

ECK

N

P

O

P2264 WATER IN FUEL SENSOR

DTC Logic

INFOID:0000000010290043

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 1 minute before conducting the next test.

>> GO TO 2.

2.

PERFORM DTC CONFIRMATION PROCEDURE

1.

Start engine.

2.

Drive the vehicle at least 15 seconds at 5 km/h (3.11 MPH) or more.

CAUTION:

Always drive the vehicle at safe speed.

3.

Check DTC.

Is DTC detected?

YES

>> Proceed to

ECK-370, "Diagnosis Procedure"

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000010290044

1.

PERFORM DIESEL FUEL FILTER WATER DRAINING

Perform diesel fuel filter water draining. Refer to

.

Water has been detected in the fuel filter?

YES

>> GO TO 2.

NO

>> GO TO 3.

2.

CHECK FUEL CONFORMITY

Check fuel conformity.

Is fuel normal?

YES

>> Replace fuel filter.

NO

>> Drain the fuel circuit and replace the fuel filter.

3.

CHECK HARNESS CONNECTOR CONNECTIONS

Check fuel heater and water level sensor harness connector connections.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair or replace error-detected parts.

4.

CHECK FUEL HEATER AND WATER LEVEL SENSOR POWER SUPPLY AND GROUND CIRCUIT

Check water level sensor power supply and ground circuit for open and short.

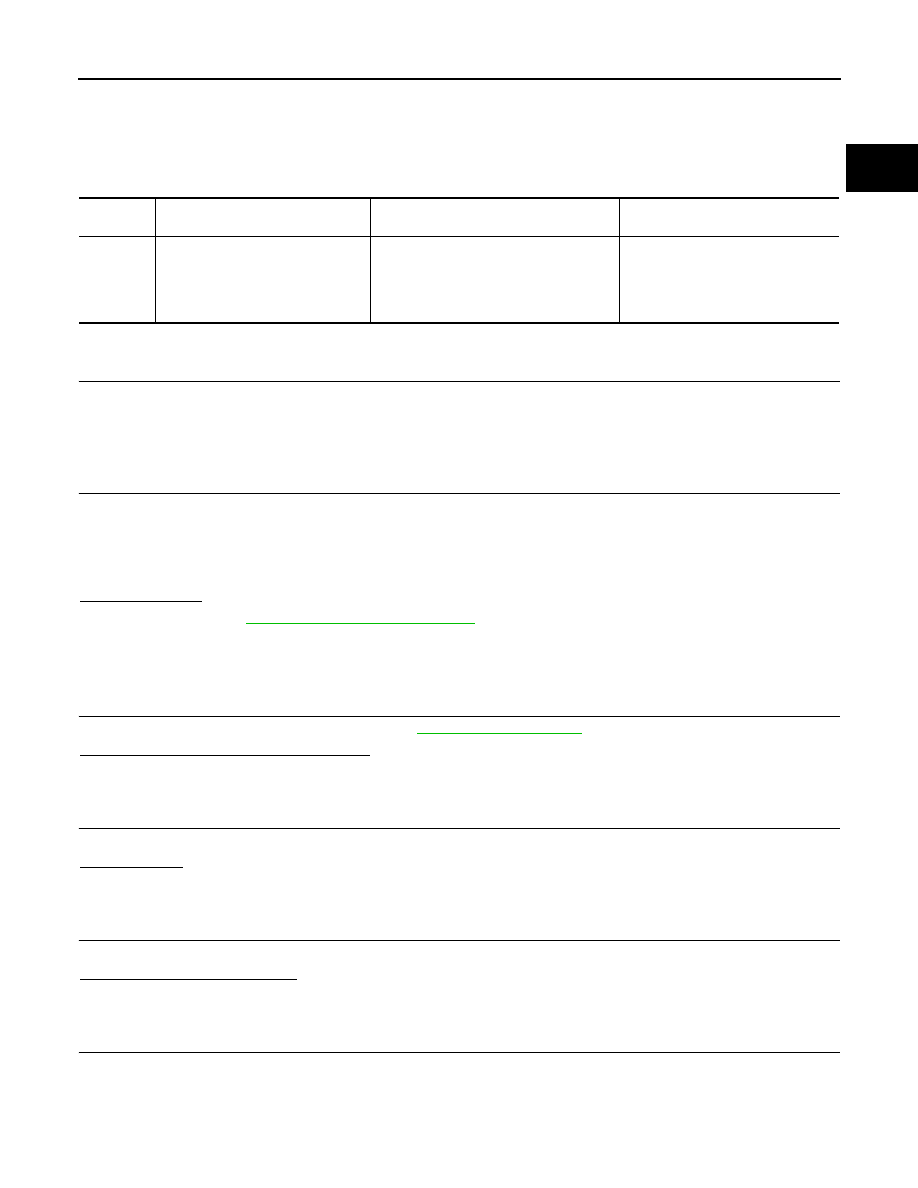

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P2264

WTR DIESEL DETECTR

(Water in fuel sensor circuit)

• CO: OPEN CIRCUIT ON THE

LINE OR PRESENCE OF WA-

TER IN THE DIESEL

• A signal from the detection sensor is

sent to ECM for 8 seconds.

• ECM detects detection sensor circuit is

open circuit for 8 seconds.

• Harness or connectors

(Detection sensor circuit is open.)

• Fuel heater and water in fuel level

sensor

• Fuel filter