Qashqai J11. Engine control system (K9K) - part 18

P0627 FUEL PUMP

ECK-273

< DTC/CIRCUIT DIAGNOSIS >

[K9K]

C

D

E

F

G

H

I

J

K

L

M

A

ECK

N

P

O

YES

>> GO TO 5.

NO

>> Repair or replace error-detected parts.

5.

CHECK IPDM E/R HARNESS CONNECTOR CONNECTIONS

Check IPDM E/R harness connector connection.

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> Repair or replace error-detected parts.

6.

CHECK FUEL PUMP RELAY CIRCUIT FOR OPEN AND SHORT

1.

Turn ignition switch OFF.

2.

Check harness continuity between ECM harness connector and IPDM E/R harness connector.

Is the inspection result normal?

YES

>> Check intermittent incident. Refer to

GI-41, "Intermittent Incident"

.

NO

>> Repair or replace error-detected parts.

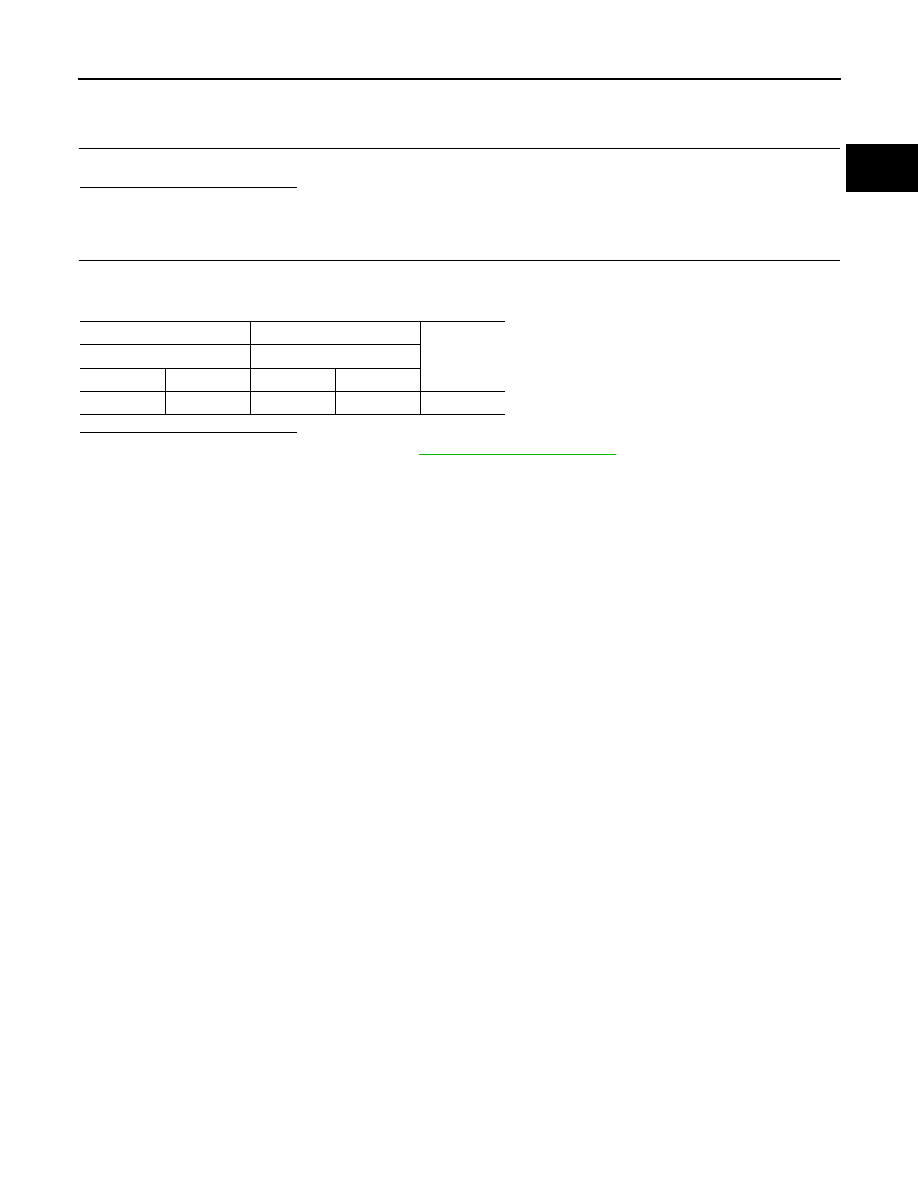

+

-

Continuity

ECM

IPDM E/R

Connector

Terminal

Connector

Terminal

F80

89

F90

106

Existed